Efficient Automation Solutions for a More Caring Future

Medical, pharmaceutical and biotechnology manufacturers stand on the cutting edge of science and technology. The broad field of life sciences is a challenging but rewarding sector: while the potential for new innovations to extend lifespans and alleviate suffering is nearly limitless, small and large firms alike face logistical, practical and regulatory hurdles. Kawasaki Robotics offers powerful and robust yet precise and flexible automation solutions that allow innovations to be scaled quickly, efficiently and profitably. For cleanroom environments, Kawasaki’s clean robots meet the healthcare industry's processing equipment specifications for accuracy, consistency and cleanliness, making them ideal for a wide range of assembly, dispensing, inspection and material handling applications.

Closing Productivity Gaps, Enhancing Outcomes

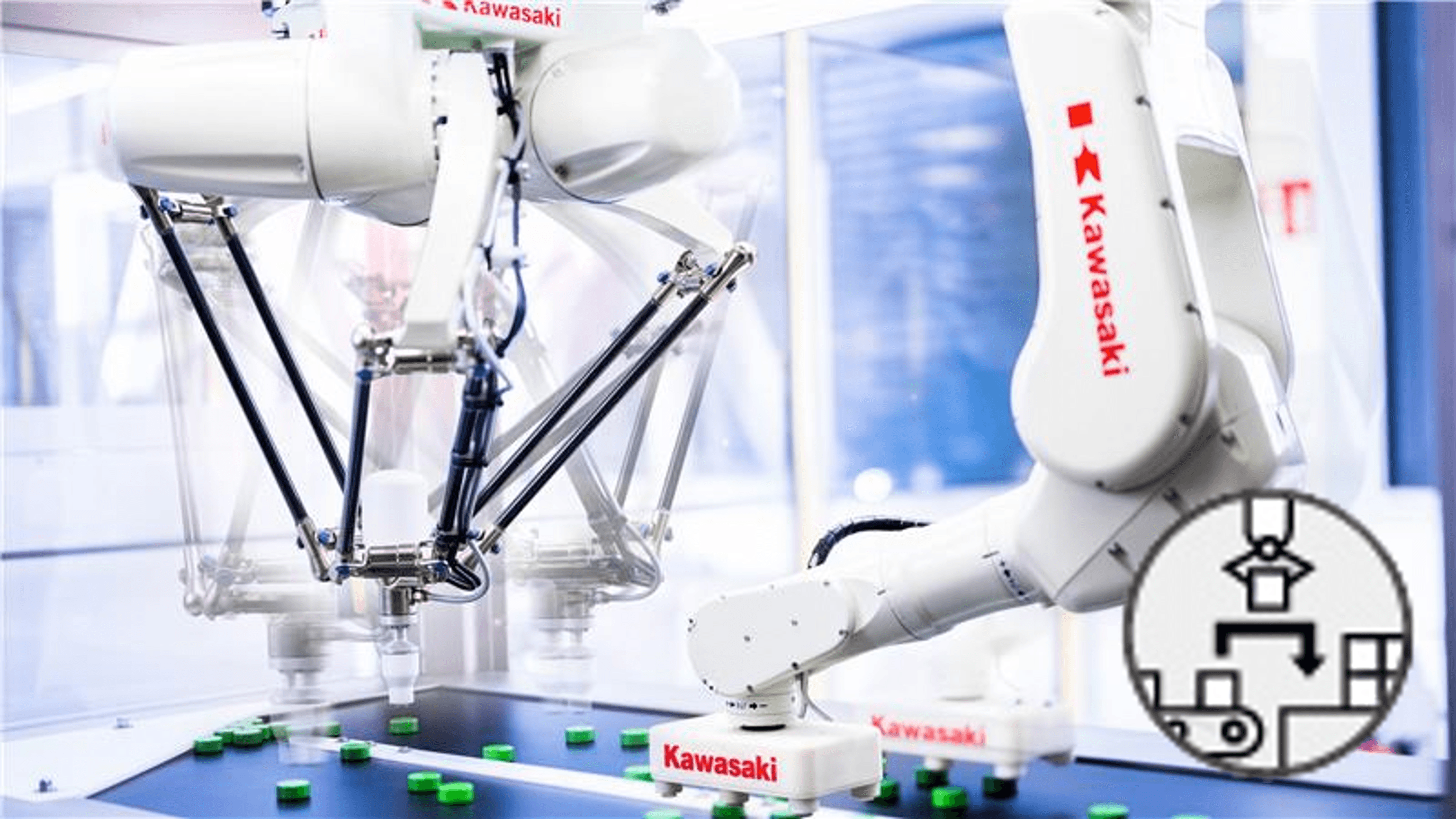

From the assembly of medical device implants and sensitive dispensing of pharmaceutical compounds to rapid, repeatable packing and palletizing operations, our precise, easily scaled life sciences automation solutions reduce profit-sapping human error while enhancing productivity, product quality and time-to-market. Kawasaki’s 6- and 7-axis robots can carry payloads of between 2 kg and 1,500 kg, making them suitable for packing and dispensing medication as well as manipulating bulky liquid containers during large-scale pharmaceutical compound production. Meanwhile, Kawasaki’s powerful software enables our gripper-equipped robots to manipulate vials, test tubes, petri dishes and assays in sensitive testing operations in cleanroom environments, including laboratories, boosting testing speed while reducing human error.

The life sciences segment is of the modern economy’s most dynamic, exciting sectors, and Kawasaki Robotics is committed to developing automation solutions that allow cutting-edge innovations to be scaled and accelerated for global good.

Ansøgninger

Materiel håndtering

Processen med at flytte materialer, dele og produkter fra et sted til et andet, materialehåndtering udføres i næsten alle industrier, ikke kun i fremstillingsindustrien.

Til materialehåndtering er industrirobotter oftest brugt til forskellige formål, herunder højhastighedstransport af små dele og håndtering af tunge genstande, som mennesker ikke kan bære.

Maskinpleje

En kritisk proces i maskinindustrien, maskinpleje involverer indlæsning af dele i NC-værktøjsmaskiner og aflæsning af dem, efter at deres bearbejdning er færdig. Ind- og udlæsning af forarbejdningsmaterialer ind og ud af smede- og pressemaskiner er også klassificeret som maskinpleje.

Pick & Place

Plukning, også kendt som "pluk og placer", er processen med at gribe emner fra et transportbånd og sortere dem ved høj hastighed.

Til dette formål bruges unikt formede robotter kaldet parallellink-typen (eller delta-typen).