Efficient Automation Solutions for a More Caring Future

Medical, pharmaceutical and biotechnology manufacturers stand on the cutting edge of science and technology. The broad field of life sciences is a challenging but rewarding sector: while the potential for new innovations to extend lifespans and alleviate suffering is nearly limitless, small and large firms alike face logistical, practical and regulatory hurdles. Kawasaki Robotics offers powerful and robust yet precise and flexible automation solutions that allow innovations to be scaled quickly, efficiently and profitably. For cleanroom environments, Kawasaki’s clean robots meet the healthcare industry's processing equipment specifications for accuracy, consistency and cleanliness, making them ideal for a wide range of assembly, dispensing, inspection and material handling applications.

Closing Productivity Gaps, Enhancing Outcomes

From the assembly of medical device implants and sensitive dispensing of pharmaceutical compounds to rapid, repeatable packing and palletizing operations, our precise, easily scaled life sciences automation solutions reduce profit-sapping human error while enhancing productivity, product quality and time-to-market. Kawasaki’s 6- and 7-axis robots can carry payloads of between 2 kg and 1,500 kg, making them suitable for packing and dispensing medication as well as manipulating bulky liquid containers during large-scale pharmaceutical compound production. Meanwhile, Kawasaki’s powerful software enables our gripper-equipped robots to manipulate vials, test tubes, petri dishes and assays in sensitive testing operations in cleanroom environments, including laboratories, boosting testing speed while reducing human error.

The life sciences segment is of the modern economy’s most dynamic, exciting sectors, and Kawasaki Robotics is committed to developing automation solutions that allow cutting-edge innovations to be scaled and accelerated for global good.

Aplicaciones

Manipulación de materiales

El proceso de mover materiales, partes y productos de un lugar a otro, el manejo de materiales se realiza en casi todas las industrias, no solo en la industria manufacturera.

Para el manejo de materiales, los robots industriales se usan más comúnmente para varios propósitos, incluido el transporte a alta velocidad de piezas pequeñas y el manejo de objetos pesados que los humanos no pueden transportar.

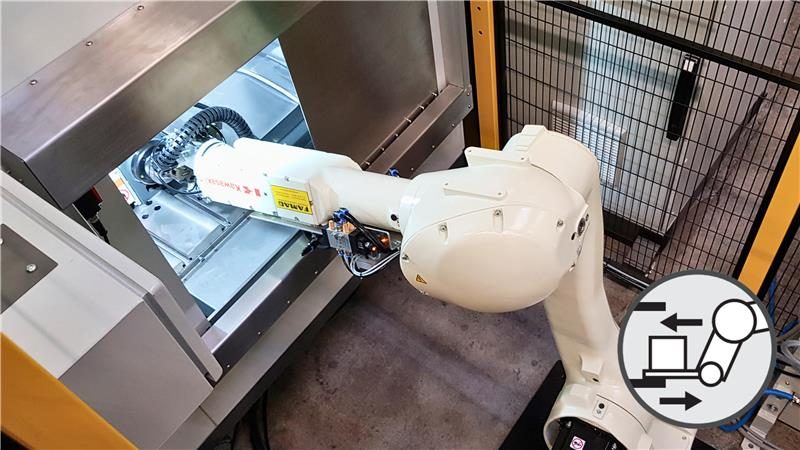

Cuidado de la máquina

Un proceso crítico en la industria de la maquinaria, la atención de máquinas implica cargar piezas en máquinas herramienta NC y descargarlas una vez que se completa el mecanizado. La carga y descarga de materiales de procesamiento dentro y fuera de las máquinas de forjado y prensado también se clasifica como cuidadora de máquinas.

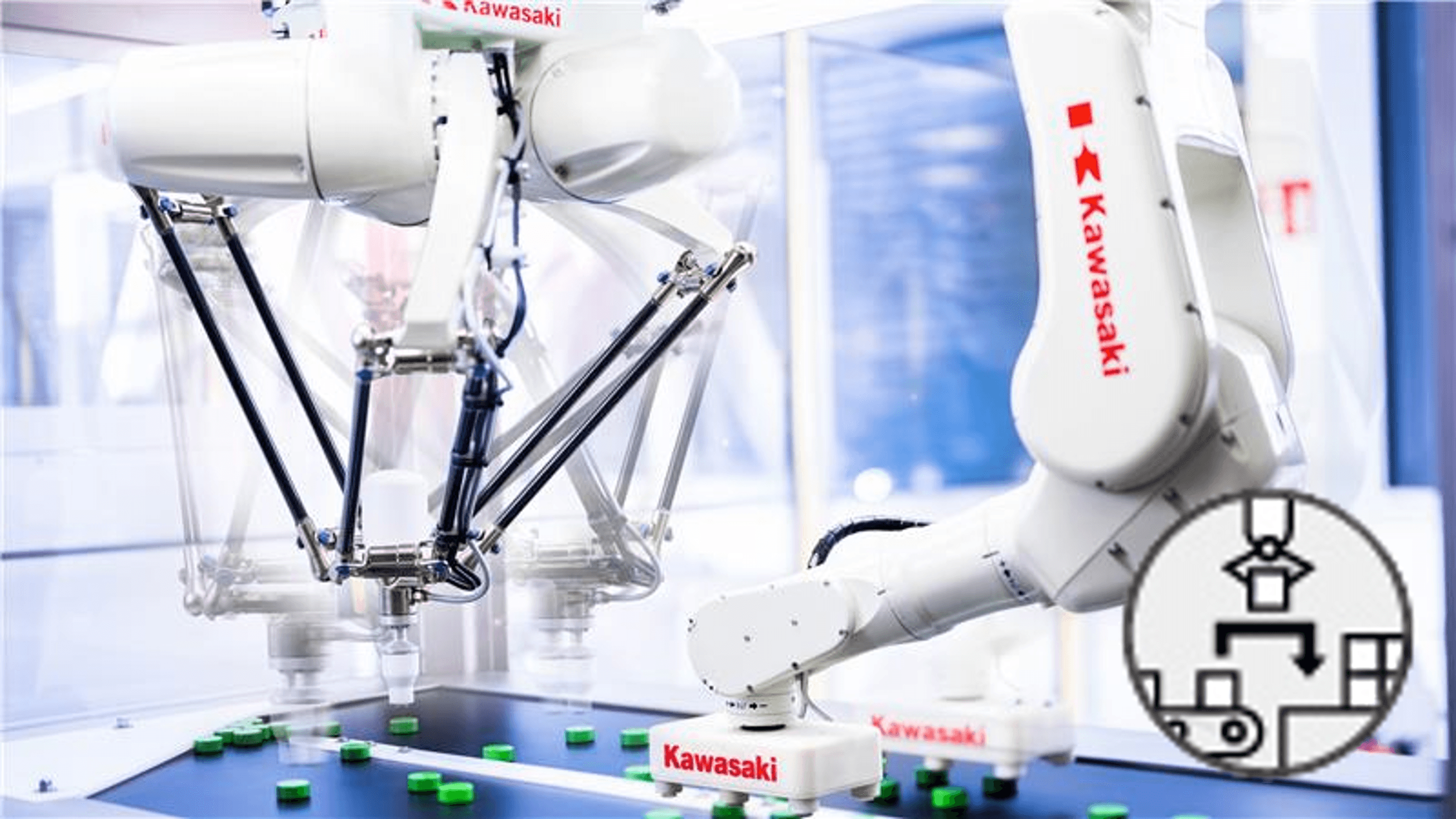

Escoger y colocar

La recolección, también conocida como "recoger y colocar", es el proceso de tomar piezas de trabajo de una cinta transportadora y clasificarlas a alta velocidad.

Para este propósito, se utilizan robots de forma única llamados tipo de enlace paralelo (o tipo delta).