Driving Innovation and Creating Value in a Competitive Industry

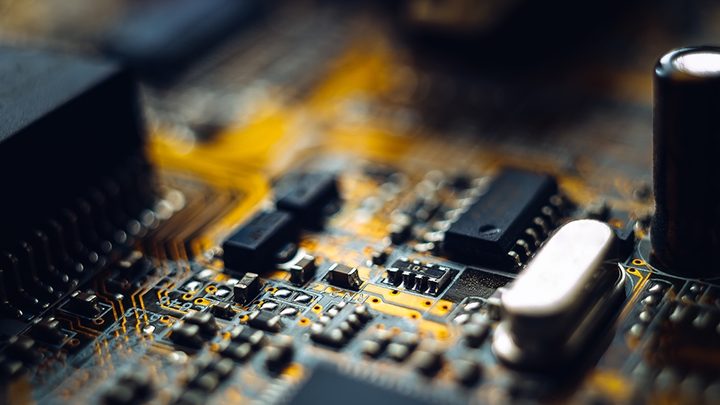

Since the development of the first semiconductors, the electronics industry has benefited from one groundbreaking innovation after another. As the cost of raw materials for chips, fiber cables, circuits and other critical electronics components falls, manufacturers have turned to next-generation robotics solutions to enhance operational efficiency and reduce labor costs without harming the quality and precision of finished equipment. Kawasaki Robotics has leveraged advancements in miniaturization and production speed to develop flexible, precise automation solutions for a variety of electronics applications.

Efficient Production, Consistent Results

Kawasaki Robotics' multi-position robots leverage human-quality dexterity to stamp, etch, press and handle small, lightweight semiconductor electronic components. Since they can be moved to multiple positions along the production line, they can easily execute component and final assembly tasks for consumer electronics like microwave ovens, desktop and laptop computers, mobile devices and location-finding systems with precision that far exceeds the capabilities of human workers. Meanwhile, their next-generation machine vision and sensing capabilities make Kawasaki robots ideal for inspection and quality control processes. After assembly, our flexible robots expertly palletize and pack sensitive equipment for delivery while disposing of leftover materials. Kawasaki's solutions augment every facet of the electronic assembly process.

電子創新步伐不斷加快。隨著 RFID、手持通信設備、寬帶連接器、片上系統應用和其他有前途的技術製造商出現新的機遇,川崎機器人公司承諾為互聯的未來開發靈活、精確的自動化解決方案。

應用

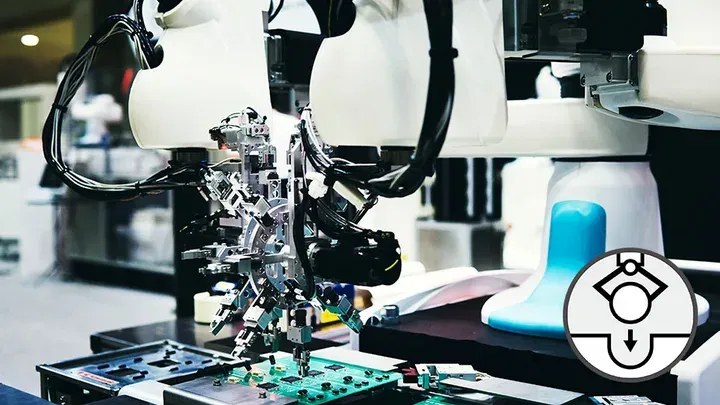

組裝

The process of combining multiple parts to make components or products, assembly is performed in various manufacturing sectors, including machinery, electronics, and electrical sectors.

Assembly covers various tasks, including assembly of small precision parts and large and heavy workpieces.

來料搬送

將材料、零件和產品從一個地方移動到另一個地方的過程,材料處理幾乎在所有行業中進行,而不僅僅是在製造業中。

對於物料搬運,工業機器人最常用於各種用途,包括小零件的高速運輸和人類無法搬運的重物的搬運。

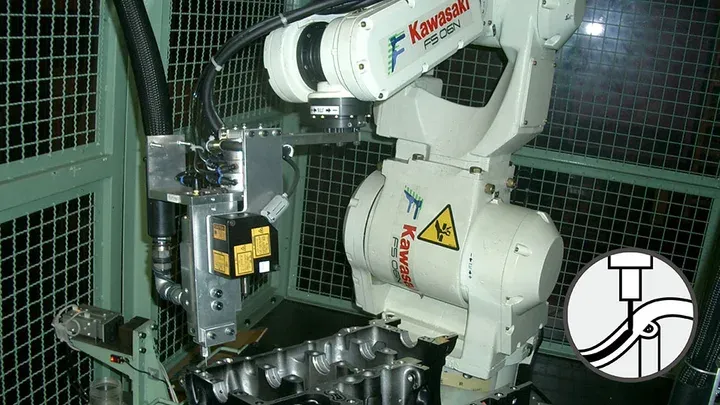

機台上下料

作為機械行業的一個關鍵過程,機器維護包括將零件裝載到 NC 機床中,並在加工完成後卸載它們。將加工材料裝入和取出鍛壓機和壓力機也被歸類為機器維護。

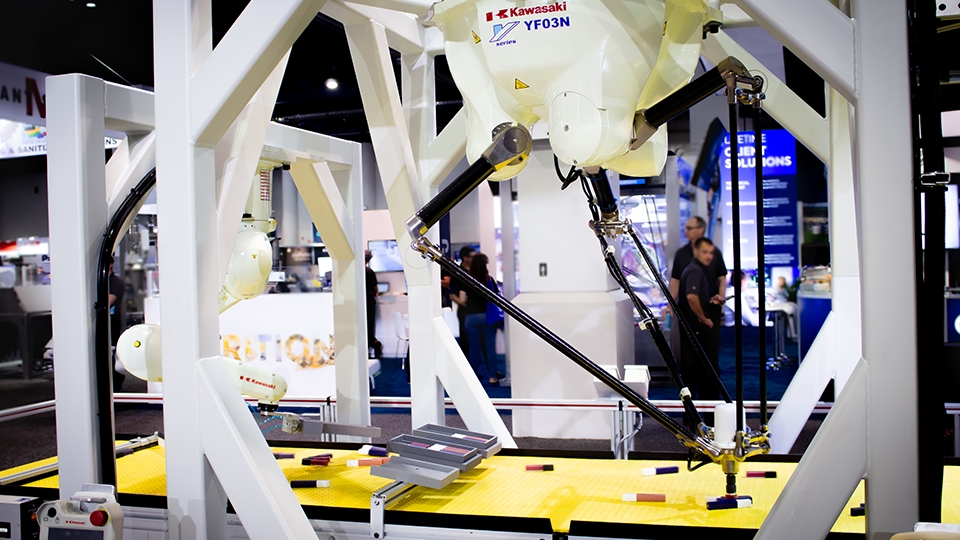

取放

拾取,也稱為“拾取和放置”,是從傳送帶上抓取工件並高速分揀的過程。

為此,使用了稱為平行連桿型(或三角型)的獨特形狀的機器人。

塗裝

Painting is the process of applying paint on product surfaces, forming a coating film or finish.

Because most paint materials are highly volatile, explosion-proof robots and painting equipment are used for this process.

封裝/塗膠

Sealing is the process of applying sealant or adhesive to enhance airtightness and fill the space between materials.

Sealing is performed for many products, such as passenger vehicles and home appliances.

矽晶片處理

晶圓轉移是半導體製造設備前端工藝中晶圓的搬運。

這個過程使用乾淨的機器人,需要高精度、高速和平穩的運動。