- IndustriesFabrication de machines et de métaux

- ApplicationsMachines spé, Enlèvement de matière

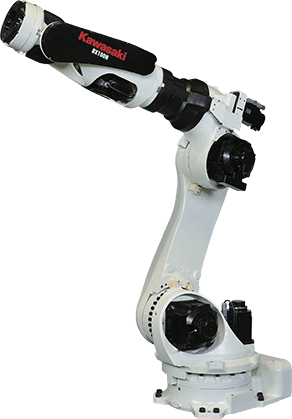

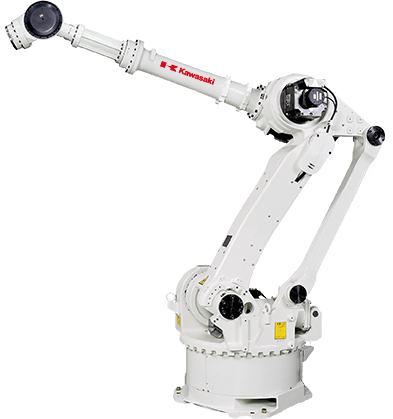

- Robot Sériesérie BX/BT, série ZX

OVERVIEW

With their double-walled underground storage tanks, German company Haase Group has been a market leader in the tank industry for more than 50 years and relies on a unique combination of traditional manual work and modern automation technology.

Since their start in 1999, Haase has recorded strong growth says Managing Director Thomas Falkenbach: « We looked for and found a market niche. This has enabled us to position ourselves successfully as a pioneer in the field of tanks – regarding material, quality and flexibility. » But in 2010, they decided to enhance their tank finishing process using Kawasaki robots and safety software.

Since the integration of the first Kawasaki robot in 2010, the traditional manufacturer has not only been able to significantly optimize its production and efficiency, but also to support its sustained growth in many industries and international markets.

CHALLENGES

Issues Stemming from Aging Robots

Haase was an early adopter of robotics, installing their first robot in 1991. This upgrade brought a noticeable relief for the company, so they continued down the path of automation. As time went on and the robots grew older, maintenance and servicing became increasingly difficult. When it was no longer possible to guarantee reliable procurement of spare parts in the long term, they knew it was time to upgrade.

Safer Work Environment for Employees

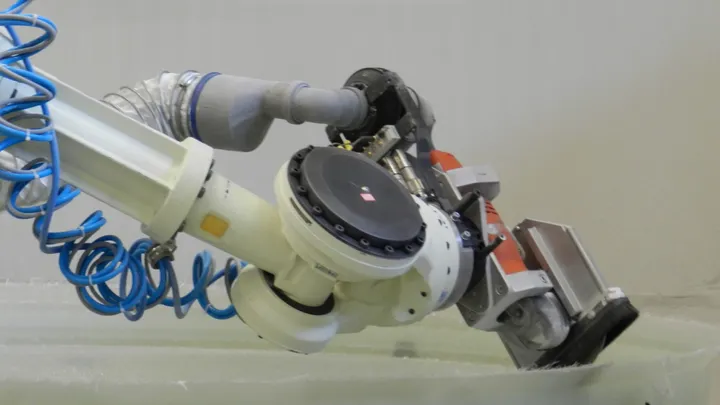

A central challenge in the construction and operation of the plant was the considerable amount of dirt and dust produced during processing. They needed a robot arm suitable for a dusty environment and a controller that didn’t require constant cleaning.

SOLUTION

- Installation of Kawasaki shelf-mounted ZT130S robot led to automating more processes

- Automatic tool change station allows robot to swap out four different tools

Haase installed the Kawasaki ZT130S robot to spray glass fiber reinforced plastic (GRP) onto the double-walled cellar and underground storage tanks during the finishing process. The robot is shelf-mounted next to a turntable where the parts are fixed, making it easy to apply an even coat of GRP.

The ZT130S robot provides the payload (130 kg) and a horizontal/vertical reach (3,230 mm/4,571 mm) needed for this application. However, its wide wide working range and high precision capabilities make it perfect for the spraying process specifically. The robot can process both single or multiple lids and bases in series, offering maximum flexibility and efficiency.

Due to the robot’s success, Haase added a Kawasaki BX100L robot to the production site to apply resin and glass fibers to a mold. They also added another ZT130L for working lids and bottoms with the automatic tool change system. This system provides them the flexibility they need to manufacture approximately 100 different tank types as needed.

Kawasaki First

Jürgen Krell, technical director at Haase, decided to go with Kawasaki Robotics after interacting with them at the Automatica trade show. « For us, the attractive price, the robust design and the specific but precisely fitting requirement profile of the robot were the deciding factors. With a proven Kawasaki partner in the neighboring town, the available service was also excellent for us. And the technical support provided by Kawasaki itself has quickly proven to be particularly reliable and flexible »

A Cleaner & Safer Environment

A suction system ensures continuous and effective extraction of dirt during the finishing process, which removed 60% of airborne dirt. The robots run on Kawasaki’s E series controller, which only needs weekly cleanings for optimal performance.

Automatic Tool Change

Haase also developed and built a special tool change station. This allows the robot to efficiently switch between four different tools needed for finishing. The shelf-mounted ZT130L robot is not dependent on special tools. It uses commercially available machines such as a milling tool to prepare the manhole in the tank and an angle grinder to prepare the tank surface for lamination and further processing. The robot also uses two saws for precise cutting and grinding, and a suction attachment for cleaning lids and bases.

Maximum Safety Enhances Human-Robot Collaboration

A light barrier effectively protects the working area of the robot in combination with the Kawasaki Cubic-S safety system. Cubic-S ensures that robots and workers can work together safely and without hesitation. The software enables the installation of particularly space-saving applications and security areas without complex external security measures. Cubic-S combines eight safety functions – including the individual definition and precise limitation of the available working space. The robot cannot exceed the specified working range limits at any time.

For this safety system to work, they must electronically monitor each individual axis of the robot. Predefined axis values form the limits of possible movements. If the system exceeds a predefined speed, engages previously stopped axes, or tools leave their intended orientation, Cubic-S automatically switches off the robot. « For us, manual work and automation are closely interwoven. Therefore, we are continuously optimizing Cubic-S and our safety setup in order to make the joint work of man and robot even easier, more effective and safer, » says Krell.

RESULTS

- Production output has more than doubled

- More automation to come due to success of initial install

Once Haase made the decision to automate, they quickly restructured their plant. In less than three months, they completed their new robot integration. Since then, Haase has successfully automated all spraying stations in production as well.