提高生產力並提高運營效率

The aerospace industry continues to experience impressive growth. Most of the increased demand comes from airlines and private clients in emerging markets like China, India and Brazil. Additionally, aging fleets in developed markets suggest that growth may pick up there as well. Modern aerospace clients demand nothing short of perfection from their suppliers. Even as rising costs for materials and skilled labor squeeze manufacturers' margins, buyers facing their own cost pressures - expensive fuel, bulky labor contracts and regulatory hurdles - are balking at higher prices for finished equipment. Robotic automation of production and inspection processes helps aerospace manufacturers meet these demands and keep one step ahead of the competition by increasing productivity, lowering finished product costs and improving quality.

Unlike human employees, Kawasaki robots can detect minuscule variations in the thickness, patency and integrity of airfoils and aircraft skins; they can also uniformly apply paint coatings and remove thin layers of material within extremely tight tolerances, improving aircraft fuel efficiency by reducing in-flight drag. Our flexible, high-precision robots are quickly gaining widespread acceptance for their ability to execute sensitive, repetitive tasks, including bolting, riveting and welding interior and exterior sections of aircraft, as well as general assembly processes - all while meeting strict international standards of precision and quality that ensure passenger and crew safety.

應用

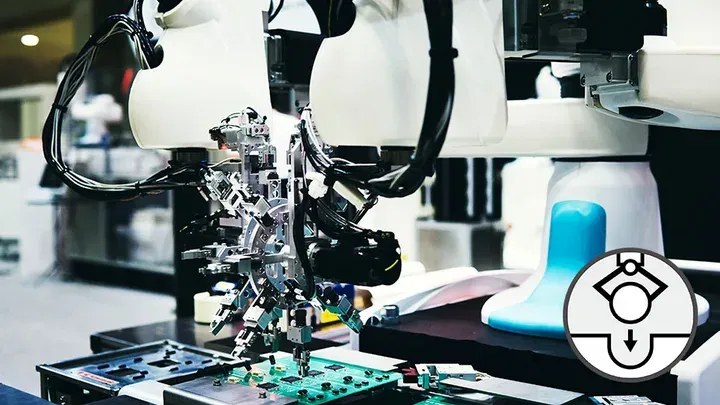

組裝

將多個零件組合起來製造零件或產品的過程,組裝在各種製造業中進行,包括機械、電子和電氣行業。

組裝涵蓋各種任務,包括小型精密零件和大型重型工件的組裝。

物料搬運

將材料、零件和產品從一個地方移動到另一個地方的過程,材料處理幾乎在所有行業中進行,而不僅僅是在製造業中。

對於物料搬運,工業機器人最常用於各種用途,包括小零件的高速運輸和人類無法搬運的重物的搬運。

機台上下料

作為機械行業的一個關鍵過程,機器維護包括將零件裝載到 NC 機床中,並在加工完成後卸載它們。將加工材料裝入和取出鍛壓機和壓力機也被歸類為機器維護。

堆棧

在托盤上堆放箱子、袋子、瓶子和其他產品的過程,碼垛通常用於製造業以及物流業的運輸。另一方面,卸垛是相反的過程,產品按順序從托盤上卸下。

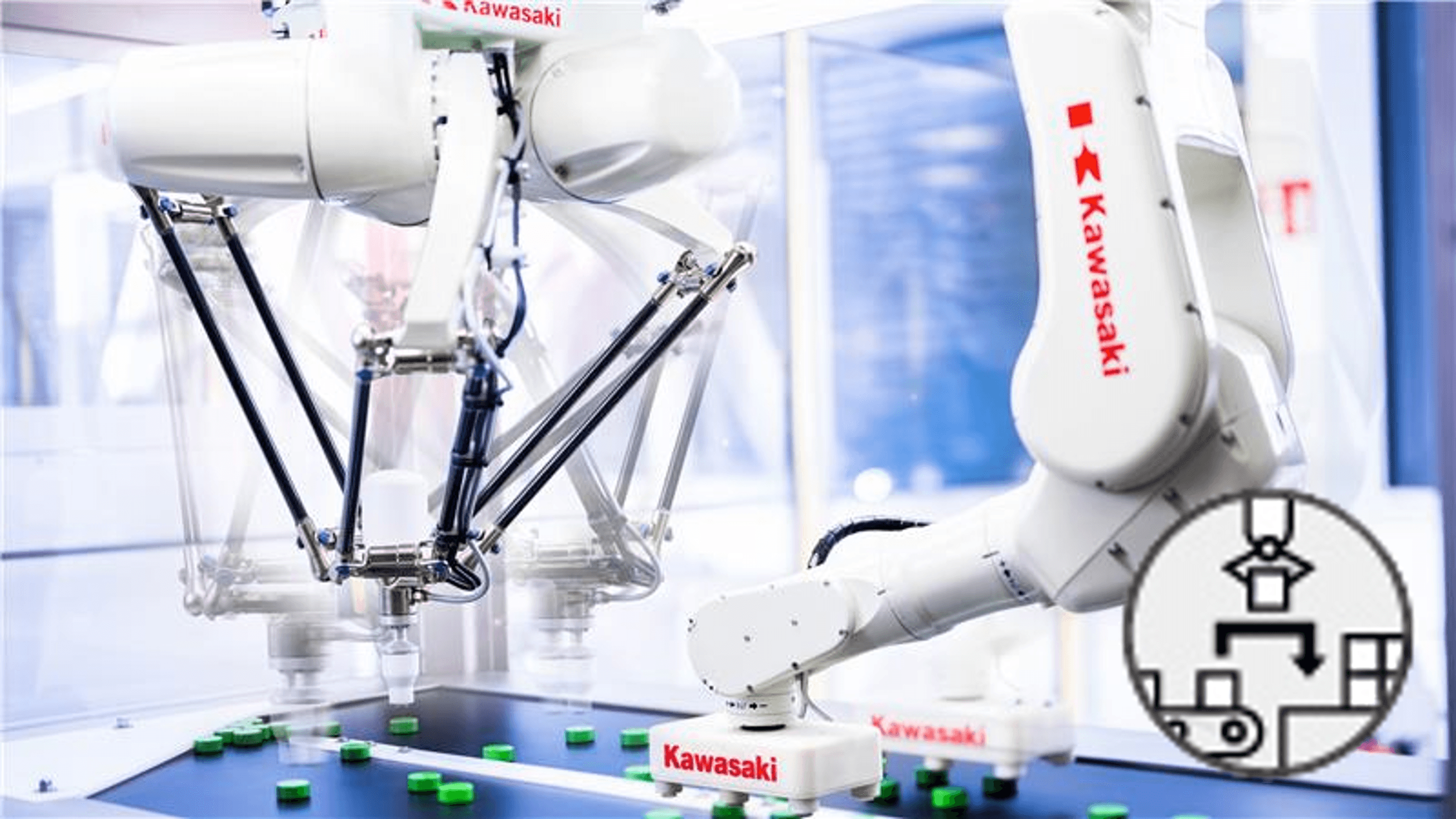

取放(揀選)

揀選,也稱為“拾取和放置”,是從輸送帶上抓取工件並高速分揀的過程。

為此,使用了稱為平行連桿型(或三角型)的獨特形狀的機器人。

塗裝

塗裝是將油漆塗在產品表面,形成塗膜或面漆的過程。

由於大多數油漆材料具有高度揮發性,因此該過程使用防爆機器人和塗裝設備。

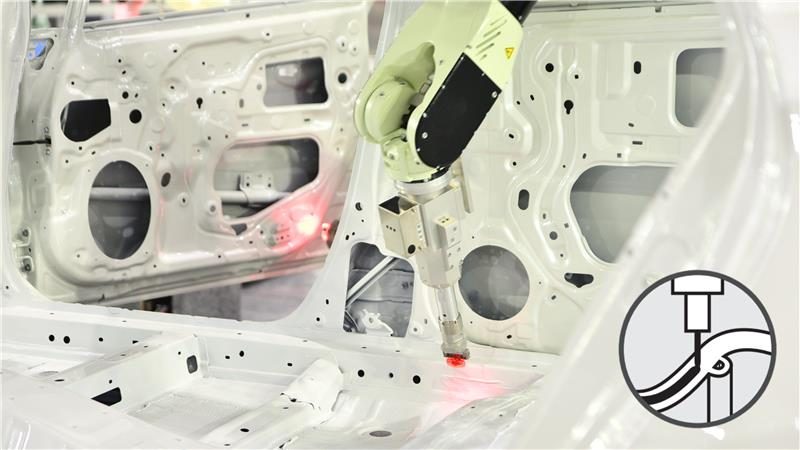

封裝/塗膠

密封是應用密封劑或黏合劑以增強氣密性並填充材料之間空間的過程。

許多產品都需要進行密封,例如乘用車和家用電器。

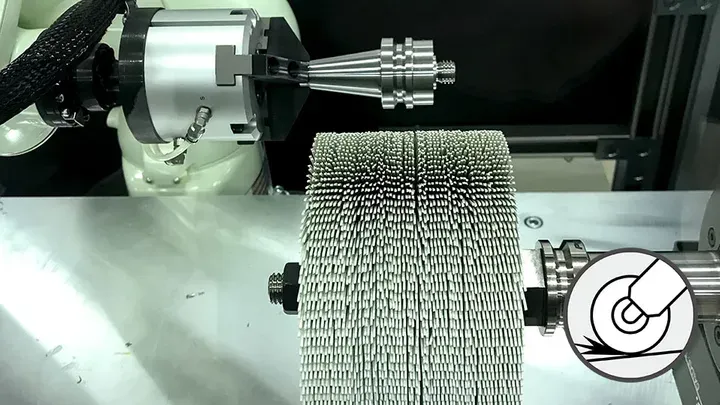

材料去除

打磨去毛邊是去除鑄鍛件表面以及焊接後表面突出毛邊的製程。

涉及用磨床刮掉毛刺,這個過程可能很髒、危險且要求很高,而機器人可以在其中發揮重要作用。