Reducing Costs, Improving Safety

As guardians of a critical resource - the world's food supply – food and beverage operators rely on predictable, easily replicated packaging, handling and transportation solutions to ensure the safety, quality and abundance of their products. In a globalized market for consumables, operators at every step of the supply chain must leverage cutting-edge robotics to remain profitable, competitive and flexible. Kawasaki robots can smooth out dramatic fluctuations in raw material costs and product mix and specifications with cost-effective and flexible in-process handling and end-of-line palletizing automation solutions.

Automation for Modern Food & Beverage Producers

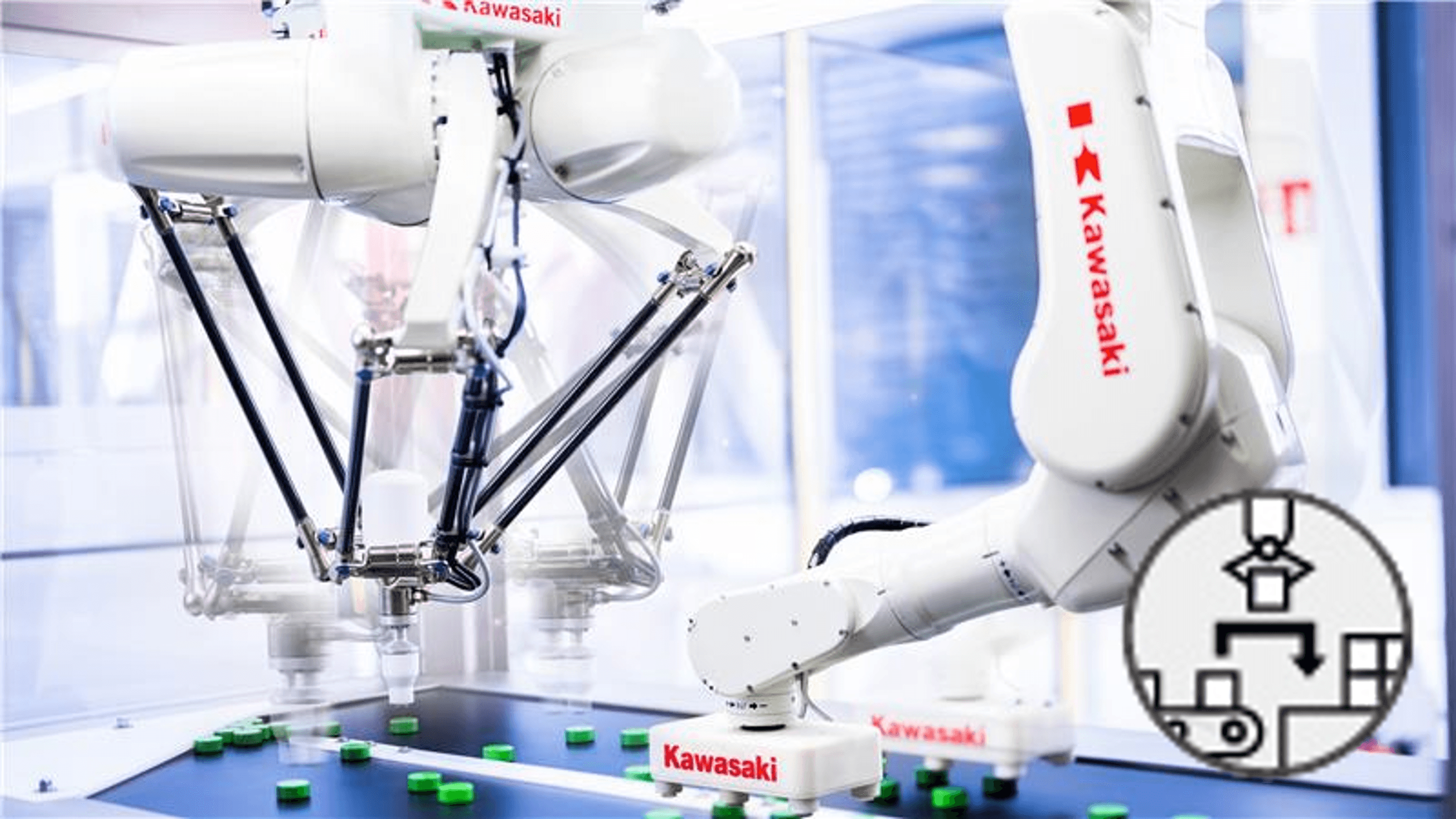

From soda bottling plants to dairy processing facilities, Kawasaki's food and beverage robots meet hygiene requirements and fulfill a wide range of handling processes, including bottle positioning, capping, filling, sterilizing and high-speed picking and sorting as well as repetitive but precise food handling operations like the packaging of irregularly shaped items and variety packs. Elsewhere on the production floor, our reliable robots assist with loading and unloading of packaging and sorting machines as well as palletizing of packaged dairy, meat and beverage products for transfer and shipment. Our cold- and heat-resistant robots can even execute dexterous materials processing and handling operations as well as packing and palletizing processes in adverse working environments in continuous fashion with speed, enhancing productivity and boosting fulfillment while improving worker welfare.

As food and beverage operators demand ever greater precision and safety from their production operations, Kawasaki Robotics continues to develop cutting-edge solutions that reduce waste, boost profit and enhance the safety of the food supply.

應用

物料搬運

將材料、零件和產品從一個地方移動到另一個地方的過程,材料處理幾乎在所有行業中進行,而不僅僅是在製造業中。

對於物料搬運,工業機器人最常用於各種用途,包括小零件的高速運輸和人類無法搬運的重物的搬運。

堆棧

在托盤上堆放箱子、袋子、瓶子和其他產品的過程,碼垛通常用於製造業以及物流業的運輸。另一方面,卸垛是相反的過程,產品按順序從托盤上卸下。

取放(揀選)

揀選,也稱為“拾取和放置”,是從輸送帶上抓取工件並高速分揀的過程。

為此,使用了稱為平行連桿型(或三角型)的獨特形狀的機器人。