適用於惡劣環境的重型機器人技術解決方案

As a persistent economic slump trims global demand, nimble, cost-competitive foundry operators across the developing world have increased competitive pressure for ferrous and non-ferrous metal castings. For manufacturers in the developed world, this supports the business case for the adoption of robust, heat-resistant robots that can withstand the hostile environments and heavy workpieces of modern foundries, provide the flexibility needed to produce quality castings that meet each client’s specifications, and reduce production costs. Kawasaki Robotics’ foundry automation solutions help foundry operators achieve a critical competitive edge while ensuring the safety of their employees.

削減成本,提高質量

Our heavy-duty foundry robots can handle payloads of up to 1,500 kg and feature ultra high-torque wrists that effectively, safely manipulate bulky payloads at every step of the manufacturing process. Kawasaki robots use an advanced link design to eliminate the need for an unwieldy counterweight that reduces turning radiuses and shrinks side-to-side clearance. These heat-resistant pieces of equipment can operate in hostile environments while executing delicate handling of molds, casting extraction operations, core assembly and setting, ladling of molten and cooling metal, and additional material removal tasks such as deburring, grinding and polishing. Thanks to flexible positioning capabilities and responsive software programming, these machines can easily be redeployed to handle changing production objectives.

Foundry operators contend with hostile working environments and increasingly competitive global markets, leaving little room for error. Kawasaki Robotics’ foundry automation solutions offer uncompromising performance without sacrificing efficiency, product quality or worker safety.

應用

物料搬運

將材料、零件和產品從一個地方移動到另一個地方的過程,材料處理幾乎在所有行業中進行,而不僅僅是在製造業中。

對於物料搬運,工業機器人最常用於各種用途,包括小零件的高速運輸和人類無法搬運的重物的搬運。

機台上下料

作為機械行業的一個關鍵過程,機器維護包括將零件裝載到 NC 機床中,並在加工完成後卸載它們。將加工材料裝入和取出鍛壓機和壓力機也被歸類為機器維護。

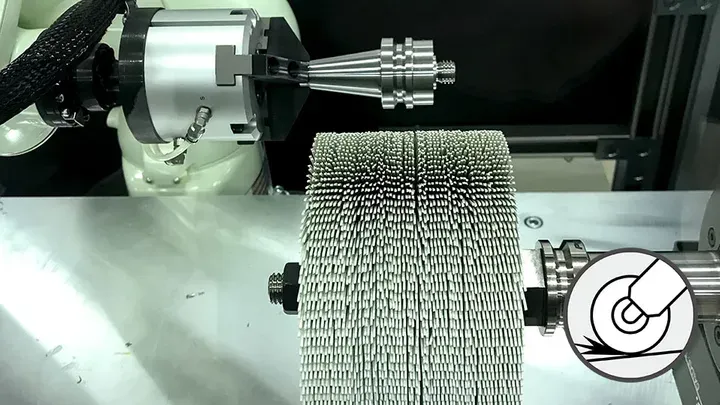

材料去除

打磨去毛邊是去除鑄鍛件表面以及焊接後表面突出毛邊的製程。

涉及用磨床刮掉毛刺,這個過程可能很髒、危險且要求很高,而機器人可以在其中發揮重要作用。