RIDUZIONE DEL 20% DEL TEMPO DI CICLO CON UN MAGGIORE CONTROLLO DEGLI SPOT

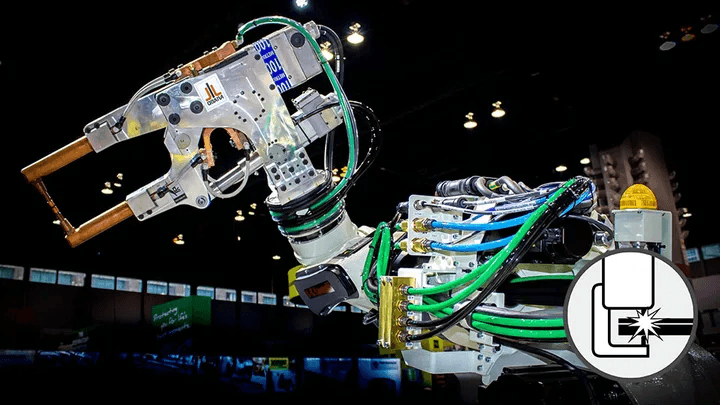

Spot welding is a resistance welding process that uses large electrical current to join two or more sheets of metal in a single location. Spot welding technology has evolved through its extensive use in automobile manufacturing using articulated robots. Kawasaki is pushing the envelope by developing spot welding automation that offers through arm cable routing, reduces cycle time, allows greater control, and reduces cost.

Kawasaki robots use an additional servo motor with a high resolution encoder to precisely control the motion of a spot welding gun. The Kawasaki spot welding software accurately controls the position, acceleration, and force of the gun. The position control and force calibration allow for different thicknesses and types of material to be welded. Kawasaki's advanced servo gun software optimizes the gun motion profile which results in an average cycle time reduction of 20%.

Kawasaki's experience with industry-leading spot welding technology can help you increase product quality, reduce production cycle time, or design and build a custom turnkey spot welding solution.

Robot per Saldatura a punti

Robot industriali per carichi medi

Per lavorazioni più impegnative, questa gamma copre carichi da 100 a 300 kg, mantenendo velocità e precisione in ambienti produttivi complessi.