What is 2D Vision?

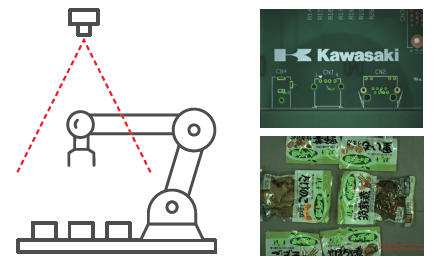

2D vision is used to accurately recognize parts and products on a flat surface and to correct their position and orientation. For example, it can locate products flowing on a conveyor, read QR codes and barcodes, and inspect labels for printing and defects. It does not handle height information, but is ideal for picking and aligning aligned workpieces.

| Object Recognition | Pattern Matching |

| Position Correction | XY Coordinates and Rotation Angle |

| Picking | Workpiece on a Plane |

| Workpiece on a Plane | Simple Operation |

Object Recognition / Position Correction and Guidance Function

- Correction of XY coordinates and angle of rotation

- (no height information)

- Workpiece misalignment (positioning on 2D coordinates)

- Alignment on plane

- Identification of objects based on the color and contour of the image

- Reading of QR codes and barcodes

- Label inspection (print confirmation and defect detection)

- Positioning of parts and workpieces on a flat surface

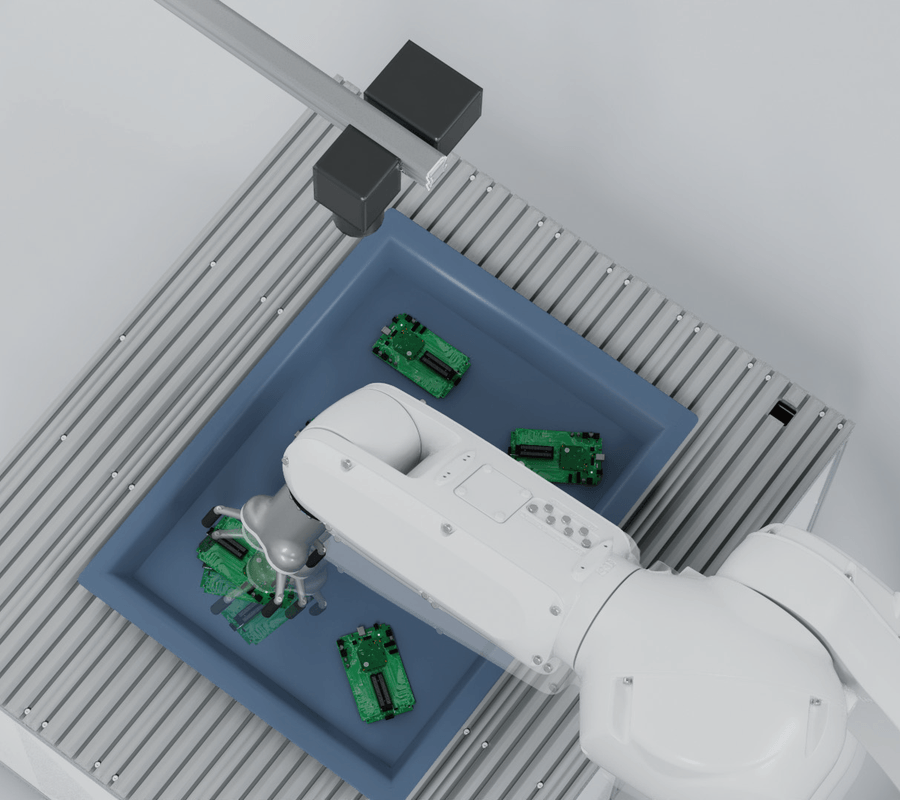

Picking / Depalletizing

- Picking of workpieces aligned on a flat surface

- Positioning of parts flowing on a conveyor

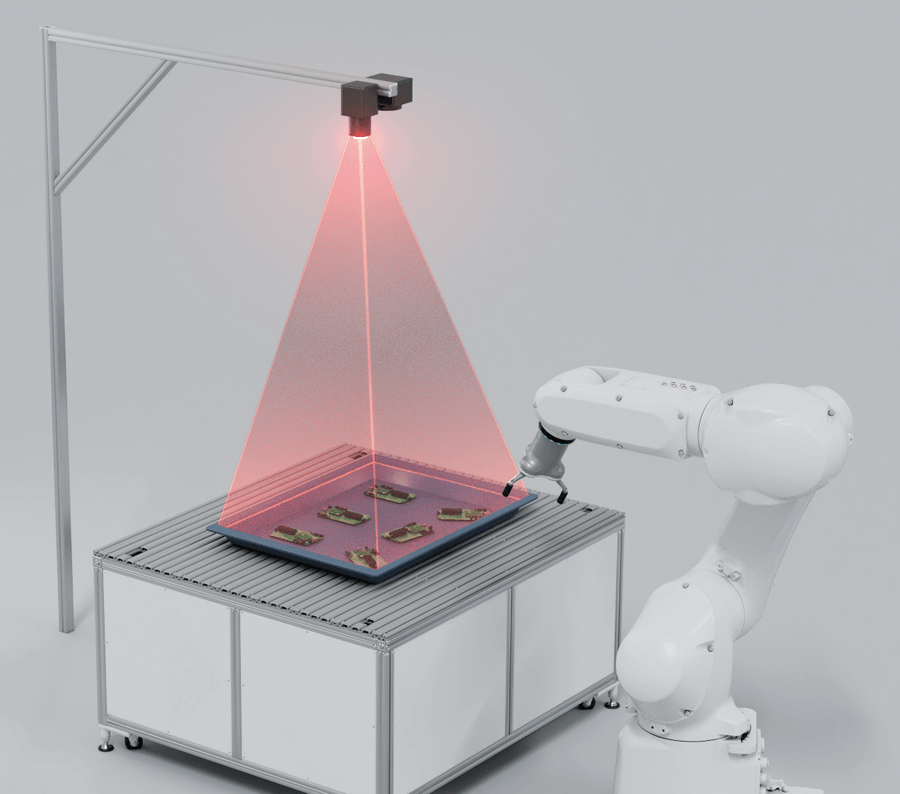

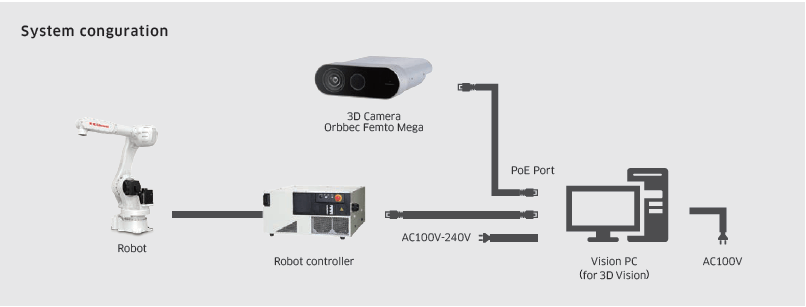

2D vision system configuration

Case Study

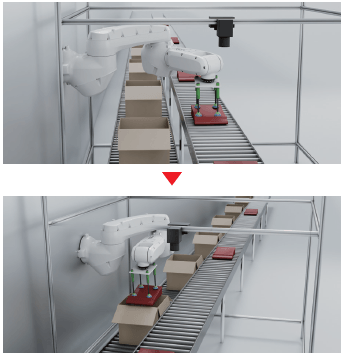

Cartoning system with vision recognition

MWES, a certified system integrator by Kawasaki Robotics based in Michigan, USA has built a flexible cartoning automation cell using conveyor trackers and vacuum grippers by combining Kawasaki’s small general-purpose robot RS007L with vision software “K-VFinder” to address labor shortages and the handling of various product types and box sizes in the food and beverage industry. The system accurately tracks the flowing bag product through vision recognition and determines the optimal picking position in real time, achievaing a high speed of 80 bags per minute and immediate response to different box sizes, reducing labor equivalent to three workers and achieving high productivity.