Increase Productivity and Boost Your Operation's Efficiency

The aerospace industry continues to experience impressive growth. Most of the increased demand comes from airlines and private clients in emerging markets like China, India and Brazil. Additionally, aging fleets in developed markets suggest that growth may pick up there as well. Modern aerospace clients demand nothing short of perfection from their suppliers. Even as rising costs for materials and skilled labor squeeze manufacturers' margins, buyers facing their own cost pressures - expensive fuel, bulky labor contracts and regulatory hurdles - are balking at higher prices for finished equipment. Robotic automation of production and inspection processes helps aerospace manufacturers meet these demands and keep one step ahead of the competition by increasing productivity, lowering finished product costs and improving quality.

Unlike human employees, Kawasaki robots can detect minuscule variations in the thickness, patency and integrity of airfoils and aircraft skins; they can also uniformly apply paint coatings and remove thin layers of material within extremely tight tolerances, improving aircraft fuel efficiency by reducing in-flight drag. Our flexible, high-precision robots are quickly gaining widespread acceptance for their ability to execute sensitive, repetitive tasks, including bolting, riveting and welding interior and exterior sections of aircraft, as well as general assembly processes - all while meeting strict international standards of precision and quality that ensure passenger and crew safety.

Applications

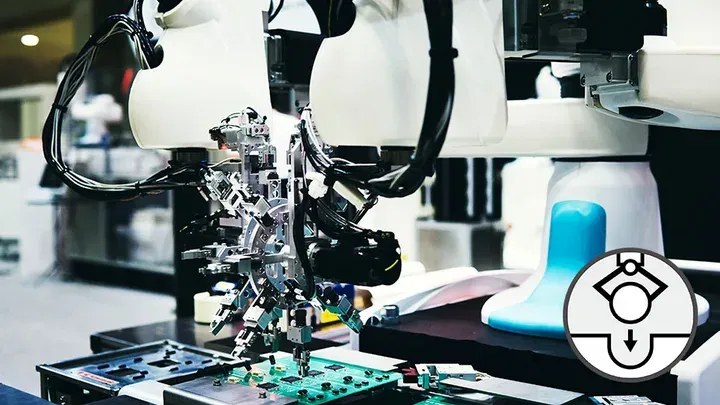

Assembly

The process of combining multiple parts to make components or products, assembly is performed in various manufacturing sectors, including machinery, electronics, and electrical sectors.

Assembly covers various tasks, including assembly of small precision parts and large and heavy workpieces.

Material Handling

The process of moving materials, parts, and products from one place to another, material handling is performed in almost all industries, not just in the manufacturing industry.

For material handling, industrial robots are most commonly used for various purposes, including high-speed transport of small parts and handling of heavy objects that humans cannot carry.

Machine Tending

A critical process in the machinery industry, machine tending involves loading parts into NC machine tools and unloading them after their machining is complete. Loading and unloading processing materials into and out of forging and press machines are also classified as machine tending.

Palletizing

The process of stacking boxes, bags, bottles, and other products on pallets, palletizing is commonly performed for shipping in the manufacturing industry as well as in the logistics industry. On the other hand, depalletizing is the opposite process, where products are unloaded from pallets in order.

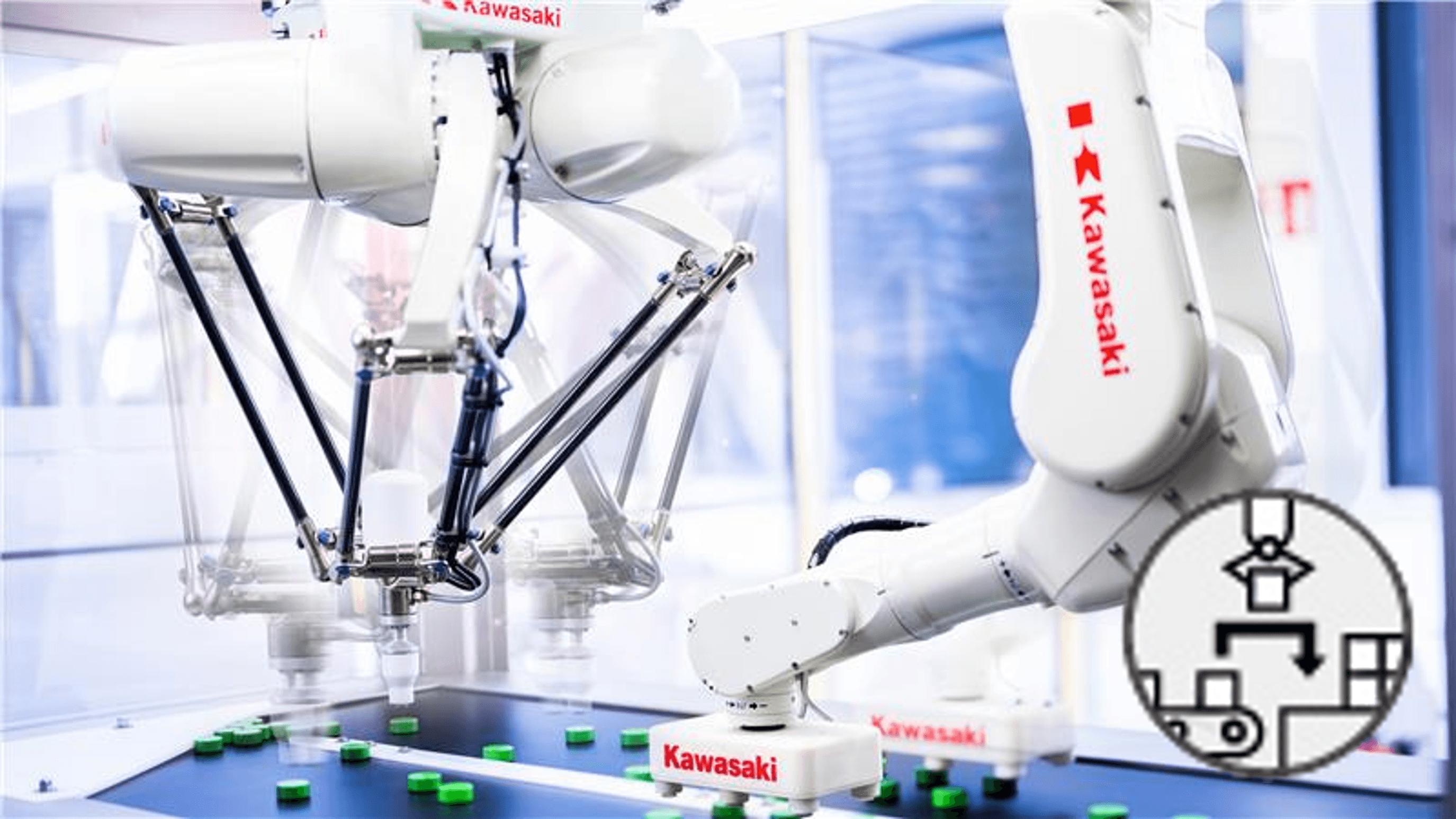

Pick & Place

Picking, also known as “pick and place,” is the process of grabbing workpieces from a conveyor belt and sorting them at high speed.

For this purpose, uniquely shaped robots called the parallel link type (or delta type) are used.

Painting

Painting is the process of applying paint on product surfaces, forming a coating film or finish.

Because most paint materials are highly volatile, explosion-proof robots and painting equipment are used for this process.

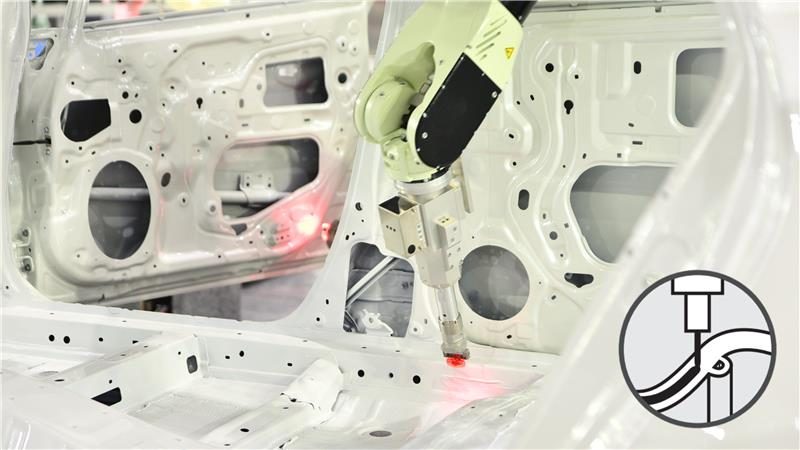

Sealing / Dispensing

Sealing is the process of applying sealant or adhesive to enhance airtightness and fill the space between materials.

Sealing is performed for many products, such as passenger vehicles and home appliances.

Material Removal

Grinding and deburring is the process of removing protruding burrs from the surfaces of casting and forged products as well as post-welding surfaces.

Involving scrapping off burrs with a grinder, this process can be dirty, dangerous, and demanding where robots can play important roles.