Case studies

1/1 Pages

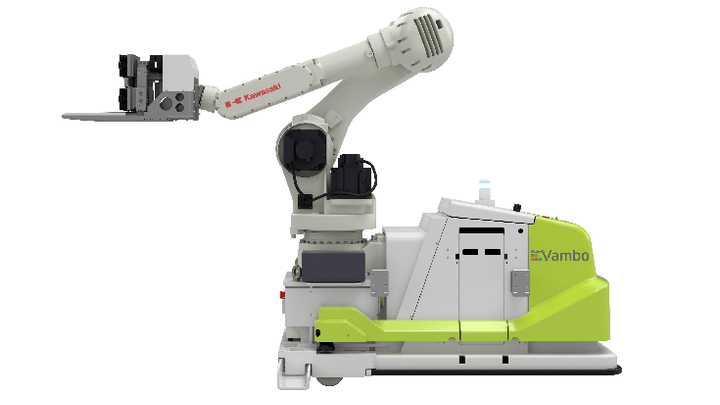

Due to the spread of COVID-19, the logistics industry has seen an explosive increase in the volume of goods handled, and automation in this industry is advancing rapidly with a focus on warehouses. By combining the versatility of robot arms with the mobility of trackless unmanned transport vehicles, Kawasaki can offer measures for the automation and optimization of logistics processes that involve automated warehouses including product receiving and shipping. Taking on the challenge of the “barriers to warehouse entry and shipment”in logistics automation In recent years, factors such as the expansion of the EC market have led to increasingly serious labor shortages in the logistics industry. Logistics labor saving and automation […]

Kawasaki Heavy Industries, or Kawasaki, is well known for its“Kawasaki”motorcycle brand. As the “Heavy Industries” in its name suggests, Kawasaki is a manufacturer of a wide range of machines from motorcycles to ships to aircraft. However, did you know that one of the core products in its lineup is robots? Kawasaki produces industrial robots that operate mainly in manufacturing sites, contributing FA. No, FA does not stand for Full Armor. It stands for Factory Automation. These robots, which Kawasaki was the first to domestically produce in Japan, are working hard in factories around the world today. Needless to say, these robots are part of the workforce in Kawasaki’s motorcycle factory as well. […]