▼ Accurate movement trajectory and tact time ▼

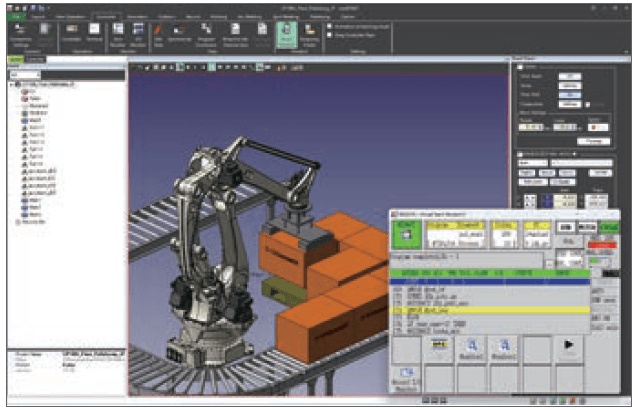

The virtual robot controller technology that Kawasaki has developed over many years enables highly accurate reproduction of movement trajectories and tact times.

▼ Supports multiple robots and external axes▼

You can simulate multiple robots with different controllers at the same time.

You can also freely reproduce external axes controlled by the robot controller.

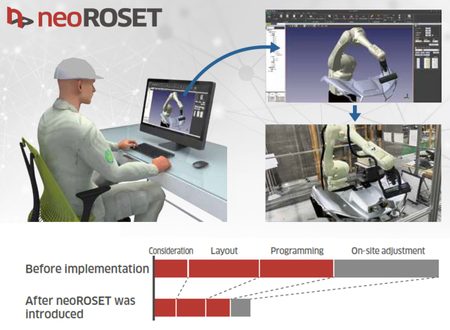

▼ Interference check, layout verification ▼

Before installing it on the actual device, you can check in advance whether there are any interference or operating range problems on your PC.

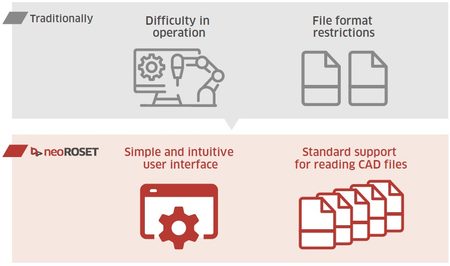

▼ CAD File Import ▼

It supports importing many types of CAD files as standard, which is useful for layout construction and CAD teaching.

▼ AS Language Editor ▼

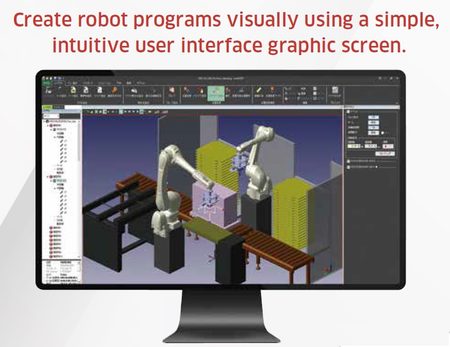

This is an editor that allows you to easily create Kawasaki robot language programs in conjunction with a graphic screen.

▼ 3D PDF Creation ▼

The actions during the simulation can be output to a file and played back in 3D using a standard PDF reader, making it useful for presentations and information sharing.

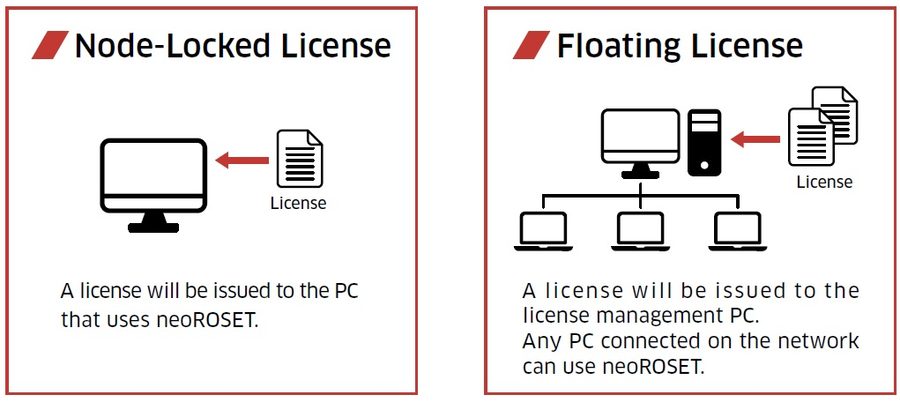

Subscription

There are two types of software licenses: node-locked and floating licenses.

System Requirements

| Item | Contents |

|---|---|

| Operating System (OS) | Windows🄬11Pro×64/WIndows(R)11 Enterprisex64 Japanese version / English version / Chinese version / German version |

| CPU | Intel Core i5 or higher recommended |

| Memory | Minimum 8GB RAM, 16GB or more recommended |

| Free space | 30GB or more, Solid State Drive (SSD) recommended |

| Resolution | 1920 x 1080 or higher recommended |

| Video card | Intel UHD Graphics or higher NVIDIA Quadro series recommended |

| Other requirements | Mouse (with wheel recommended) or equivalent pointing device PDF Reader such as Adobe® Acrobat® Reader |

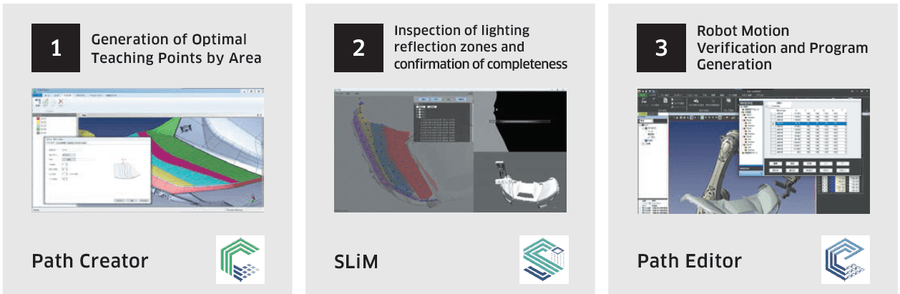

VI Planner: A Specialized Option for Visual Inspection

Previously, it was difficult to teach the robot tool to be perpendicular to complex curved surfaces, and checking the lighting reflection range with line cameras was also challenging.Kawasaki’s “neoROSET VI Planner” supports perpendicular teaching based on the target shape and automatic generation of optimal inspection paths.This enables anyone to easily and efficiently teach high-accuracy visual Inspection robots.

Note: Additional optional license is required in addition to the standard neoROSET license.

Path Creator

PathCreator is a function that automatically divides the inspection target into areas and generates the optimal inspection path for each area.

Even for complex shapes or wide inspection targets, efficient paths can be constructed based on CAD data, significantly reducing the workload of teaching operations.

SLiM

SLiM is a function that allows visual confirmation of the lighting reflection range and missed areas in the inspection paths created by PathCreator.

Since it enables verification of lighting reflections in the inspection paths generated by PathCreator, it helps reduce trial-and-error on-site and shortens startup time.

Path Editor

PathEditor is a function that allows editing of inspection paths created by PathCreator and verified by SLiM, and automatically generates robot programs.

From the verified motion, robot programs that can be used on actual machines are automatically generated.

Palletizing-Specific Optional Functions

Previously, defining palletizing patterns and handling product variations required complex layout design and programming,

often leading to errors such as collisions or misplacements.Training and operation at the site were also challenging.Kawasaki’s

neoROSET Palletizing Function simplifies this process, allowing anyone to easily configure palletizing settings. It supports

smooth and efficient implementation of palletizing robots.

※This function requires an additional optional license in addition to the standard neoROSET license.

6-Step Setup for Accurate and Efficient Palletizing

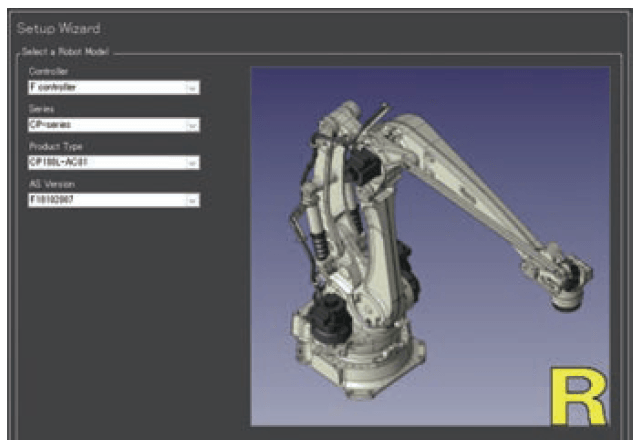

1.Select robot and material-hand

Automatically applies settings for Kawasaki R, B, Z, and M series robots, considering model-specific

motion characteristics and constraints.

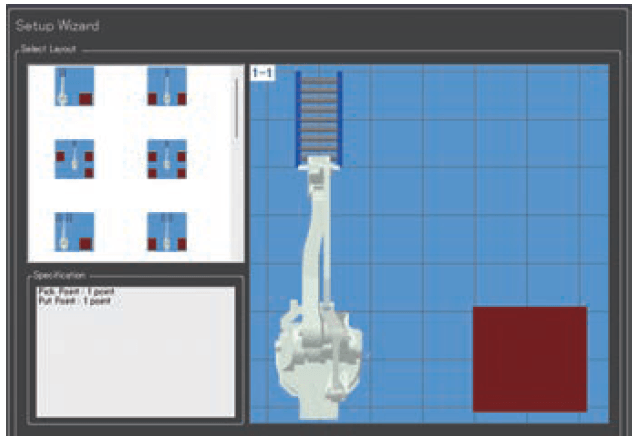

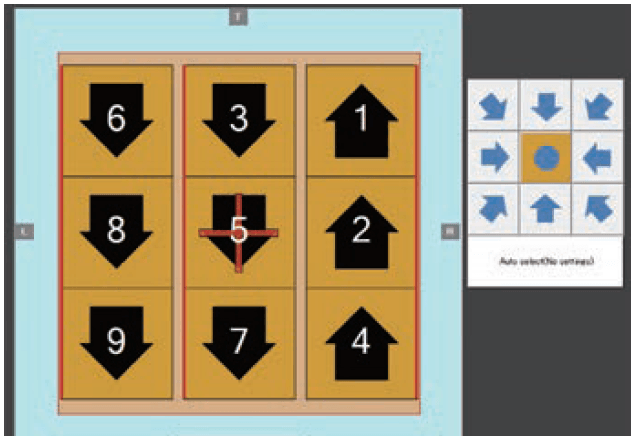

2.Choose layout pattern

Multiple layout templates are available. Simply selecting one applies the optimal configuration, significantly reducing design time.

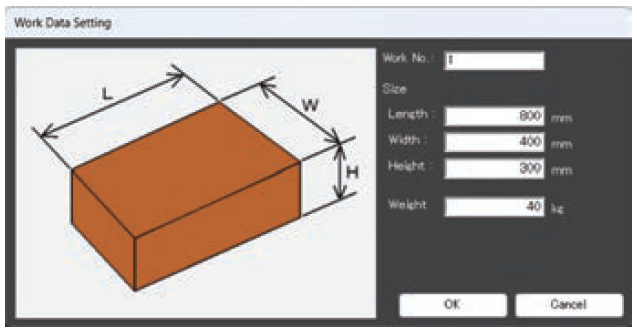

Set workpiece and pallet dimensions

Supports various shapes such as boxes and bags. Entering dimensions automatically defines stacking

conditions (height, spacing, stability, etc.).

4.Automatically generate palletizing positions

Choose from over 100 built-in patterns. Positions are generated automatically, enabling high-precision

setup even without specialized knowledge.

5.Load positions into the robot

Automatically generated position data is transferred to the robot, preventing manual input errors and enabling accurate cycle time analysis.

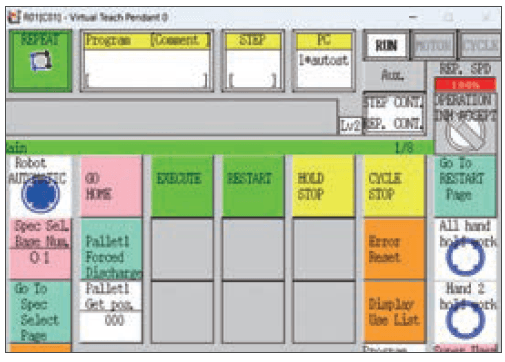

6.Execute the program

Use the virtual teach pendant (TP) for intuitive operation. Product types and pallet numbers can be set and simulated. Standard signal assignments for interlocks between upper-level controllers and the robot are also available, facilitating on-site deployment.