The new coronavirus continues to wreak havoc around the world. Economic activities are being restricted and there has been a significant impact on our lives.

According to one theory, it may take another three years before the movement of people returns to the levels before the appearance of COVID-19. It will be necessary to continue monitoring the situation of infections and reinforcing quarantine inspection systems during that time.

Kawasaki aims to realize a safe and secure society by using robots to automate PCR testing for COVID-19 virus.

Releasing medical personnel from the risk of infection

Conventionally, PCR testing has been conducted manually by medical personnel. In addition to this posing a risk of infection to the medical personnel performing the work, there were also cases where the need for human resources to conduct the testing puts pressure on the workplace. By automating the series of tasks in the testing, the risk of infection to the medical personnel is reduced and it also becomes possible to accurately perform a large number of tests.

Automated PCR testing robot system from Kawasaki

Features of the automated PCR testing robot system

- Highly accurate testing using the RT-PCR test method

- The use of robots for unmanned/automated operation makes it possible to stably perform a large number of tests in a short period of time, and to reduce the burden on medical personnel (tests are made in around 80 minutes)

- Simplified and labor-saving operation whilst maintaining safety through remote monitoring

- Large-volume testing by robots in a procedure in line with the methods recommended by the Ministry of Health, Labour and Welfare and the Medical Association.

- Use in small spaces

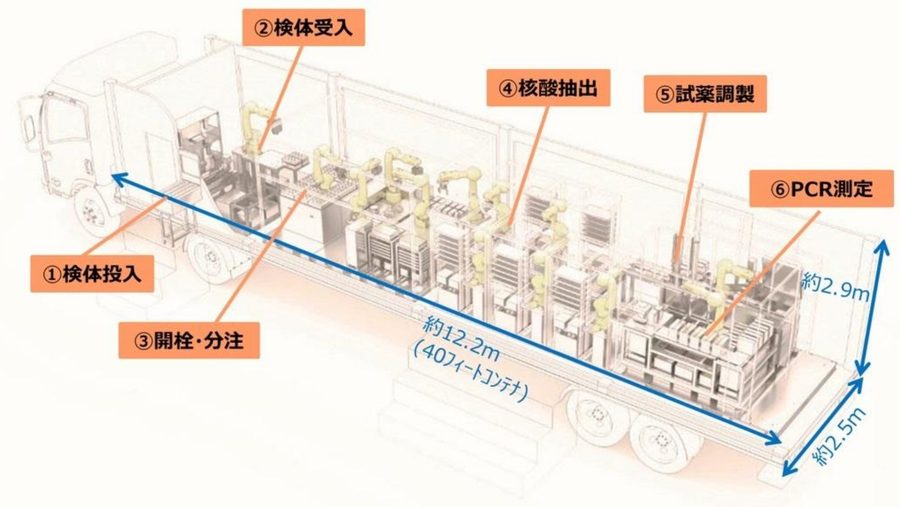

- Movement in a cargo container is possible, so utilization in various events and places is possible

The main flow of PCR testing is as follows:

Opening the lid of the container the specimen is stored in, Removing the specimen and transfer it to the culture solution container (Deep Well), and Dispensing the specimen with nucleic acid extracted to the test tubes (eight linked tubes) for the testing.

Kawasaki has used the RS Series of small general-purpose robots to construct a system that automates these tasks. This system makes it possible to reduce the time required for testing and the risk of foreign matter contamination in the specimens, and to release the medical personnel from dangerous work.

RS Series robot arm

An arm which is compact but operates at high speed and with a large motion range

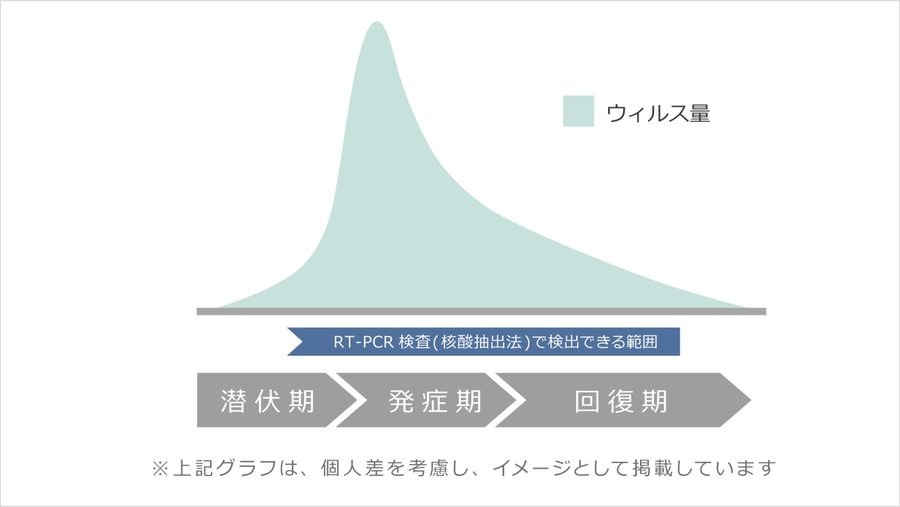

What is RT-PCR

For the method used in the PCR testing, Kawasaki has selected RT-PCR, which is the most accurate. This can detect the virus in the specimen from relatively low amounts and detection is possible immediately after infection and before symptoms appear.

Project Story: Why is Kawasaki doing PCR testing?

In March 2020, when the first wave of the new coronavirus started to wreak havoc in Japan, Kawasaki established a project within the company to utilize robot development knowledge to help medical personnel.

As part of that, the project team became aware of the situation that medical personnel were themselves being exposed to the risk of infection as they inspected large numbers of specimens. At that time, the rapid spread of infections also meant that it was a time when medical personnel resources were tight.

This became strong motivation for the project team and they presented a demonstration machine in the autumn of that same year, realizing the development in the short period of around six months from the conception.

The project makes use of Kawasaki’s robotics technology and was advanced rapidly. On January 31, 2021, the full-scale introduction to medical workplaces began. The automated PCR testing robot system from Kawasaki was installed at Fujita Health University, which had been requested by Aichi Prefecture to increase the number of PCR tests it performed, and the “Kawasaki Heavy Industries Fujita Health University PCR Testing Center” was established within the university. This made it possible to perform up to 2,500 PCR tests per day.

Kawasaki and medical care

The medical sector is a special field where detailed verification and PDCA are required. In addition, the automated PCR testing robot system also needs a cleanroom compliant and sterilization with hydrogen peroxide. Thus, the development of the system also requires expert knowledge in the medical sector, which is different from the field of industrial robots.

We were able to advance this project without delay thanks to Medicaroid Corporation (hereinafter called “Medicaroid”), which was established as a joint venture between Kawasaki Heavy Industries and Sysmex Corporation (hereinafter called “Sysmex”), which has technology in testing and diagnosis and an extensive network in the medical sector.

Medicaroid combines the knowledge in industrial robots of Kawasaki with the knowledge in the medical care and health care fields at Sysmex.

Kawasaki, Sysmex and Medicaroid will continue to support the medical field with surgical assisting robots, the PCR testing robot system and much more.

Expanding usage locations with the automated PCR testing robot system

Kansai International Airport

On May 20, 2021, the automated PCR testing robot system was installed in the departure terminal entrance of Kansai International Airport. It began offering the first PCR testing service for passengers departing on international flights in an airport in Japan.

In September 2021, we formed a business collaboration with the medical corporation TOMOHIROKAI and established a PCR testing center. We opened the “Kansai International Airport PCR Test Clinic, Medical Corporation TOMOHIROKAI” on the fourth floor of Terminal 1 at Kansai International Airport.

The PCR testing is entrusted to Kawasaki by TOMOHIROKAI and is implemented with the automated PCR testing robot system already installed in the airport. It supports a system that can issue a certificate of a negative result within three hours from the test application at the earliest.