Arc Welding

Robots

The Complete guide to finding future-ready robots-for arc welding.

What is Arc Welding?

Arc welding is the process of joining metals using the heat generated from an electric arc, and this can be done using different techniques such as MIG (Gas Metal Arc Welding), TIG (Gas Tungsten Arc Welding), PAW (Plasma Arc Welding) and more. It is a go-to method for anyone working with metal, whether in the automotive industry, construction or industrial equipment manufacturing.

How Manufacturing Companies Can Overcome ARC Welding Challenges

One of the major challenges today is the shortage of skilled welders; the American Welding Society (AWS) projects that 330,000 new welding professionals are needed by 2028 with 82,500 average welding jobs to be filled annually between 2024 and 2028 in the United States to meet the increasing demands from industry sectors such as infrastructure, energy, automotive and construction.

Now combine that with rising and constantly fluctuating material costs, supply chain disruptions and the need for customization and part flexibility, and it comes as no surprise that keeping production costs down and profit margins up is a major challenge.

Technological advancements—such as automation and advanced manufacturing processes—are needed in order to stay competitive. However, navigating this landscape can feel daunting, considering it requires time, investment and training.

The Kawasaki Robotics Difference

We have been developing our robotic welding capabilities since the 1960s, with continuous improvements in technology, techniques and quality to simplify the process of adopting arc welding technology. This helps combat labor shortages, customer demands and market conditions.

You can combine our arc welding robots with any major welding power supply. We offer a full suite of modular K positioners and K tracks, plus features like start sensing, touch sensing and adaptive fill technology—all of which come standard. Our support capabilities include through-life engineering services, training, service and support to ensure your automation project is successful.

Another key differentiator is our integrator and technology partnerships. To help remove any technology adoption barriers, we have a library of integration partners that specialize in arc welding and add another level of support. Our technology-agnostic stance and software suite allow us to work with all types of technology partners—whether you need adaptive laser vision to track the joint geometry in real time or post-process weld inspection capabilities.

Our advanced automation technology, paired with our partners, allows us to create the solution you need to reach the quality and output that you expect from an arc welding system.

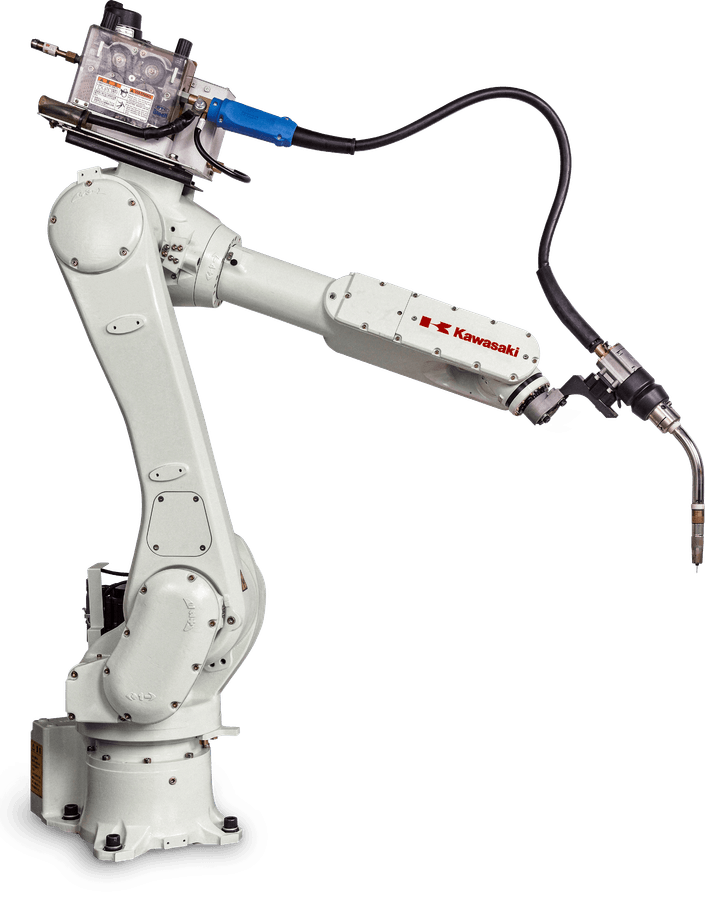

Our Arc Welding Robots

(and What Makes Them Special)

Using open architecture and state-of-the-art technology, our line of arc welding robots fully match the quality of a skilled welder. Address labor shortages, meet production goals and improve quality.

Arc Welding Robot FAQ

What is the best power supply to use for a robotic application?

What sensors are used in robotic arc welding applications?

How do I ensure precise and adaptive control of robotic welding processes?

What are the benefits of using robots for welding?

How do I optimize cycle time in robotic welding?

What safety precautions should I take when operating welding robots?

How do I handle weld seam tracking with robots?

What are the common challenges in robotic welding?

What future trends can we expect in robotic arc welding?

TALK TO KAWASAKI ROBOTICS

If your arc welding jobs are consistently pressured by labor shortages and the uncertainty of the supply chain and material costs, talk to us. Our line of arc welding robots is equipped to be a mainstay on your floor for years, if not decades.