What is AI Vision?

AI vision enables higher perception by combining AI with images acquired by 2D and 3D cameras. It can flexibly respond to workpieces with irregular shapes and arrangements, which were difficult in the previous vision, as well as new products that have not been registered. AI analyzes images and automatically determines the type and orientation of objects, streamlining complex picking and sorting tasks. It is especially effective in logistics, food, pharmaceuticals, and other sites where there are many product variations.

| 物体Object Recognition | Identification by AI, support for unregistered work |

| Position Correction | Flexible position and posture recognition with AI inference |

| Picking | Automatic identification of products with multiple types and random placement |

| Robot Cooperation | Automatic generation of efficient operation plans |

Kawasaki’s in-house AI vision system specializes in robotic picking.

It is a technology that enables complex recognition and judgment that is difficult to achieve with conventional 2D and 3D vision. The biggest features are “flexibility” and “learning ability”.

Features

Masterless operation

There is no need to register varieties and stacking patterns in advance,

and it can handle unknown workpieces and random placements.

Expandable with additional learning

Even if new shapes or special cases are distributed, recognition accuracy can be maintained by additional training by AI.

Supports unregistered or irregularly arranged workpieces

No complex programming is required, shortening the system start-up time. It can also handle unknown workpieces and random placement.

Advanced recognition capabilities

Combining 2D and 3D information with AI inference, it accurately recognizes shapes, tilts, and overlapping workpieces.

Specialty Applications

- Logistics : Unloading of consolidated containers, sorting of cardboard

- Manufacturing : Picking and assembly of various types of parts

- Food and Pharmaceuticals : Randomly placed product sorting

Case Study

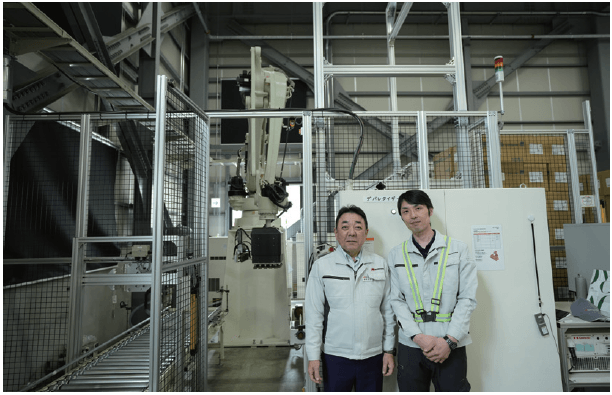

Matsuura Packing & Transportation Co., Ltd.

The Okazaki Higashi Logistics Center introduced Kawasaki’s depalletization solution to reduce the physical burden of labor shortages and heavy material handling. This system uses AI vision to recognize cases and achieve masterless operation without the need for prior variety registration or stacking pattern setting. It can flexibly handle different sizes and shapes of the case, and the robot will automatically operate by simply registering the placement position. This shortens the system start-up time and streamlines the unloading of heavy loads. In the field, the physical strain on workers is greatly reduced, contributing to a safer and more comfortable working environment.