- IndustriesAutomotive

- ApplicationsMaterial Handling

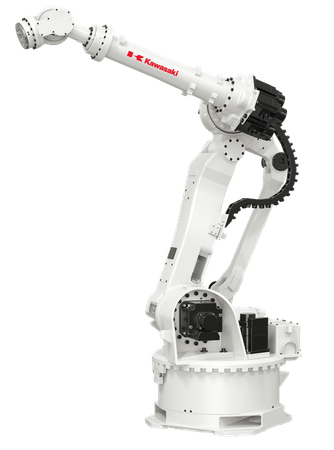

- Robot SeriesZX series

In manufacturing, the appearance quality of a product is a critical factor that influences brand value.

For leisure-use ATVs (all-terrain vehicles), it is essential to balance distinctive design aesthetics with the stability required for mass production.

To meet these needs, Kawasaki Motors, Ltd. took the bold step of automating the hydrographic transfer process at its newly established ATV manufacturing plant in Mexico.

This process is extremely important as it determines the product’s appearance. Traditionally, it was performed manually by skilled workers.

However, achieving uniform patterns on complex shapes has its limitations. To ensure both consistent quality and mass production capability, precise robotic control and advanced integration with painting systems are indispensable.

The challenge of automating this process was taken on by Kawasaki Heavy Industries’ Robot Division and IEC, a company specializing in painting systems.

This article introduces how these three parties tackled the unprecedented task of automating hydrographic transfer in Japan and achieved success at the new Mexico plant, featuring interviews with both companies.

Project Background — A Challenge Driven by Growth Vision and Technical Responsibility

Kawasaki Motors, Ltd. has set forth a growth vision toward 2030, accelerating global expansion and advancing manufacturing technologies. One of the core initiatives was the launch of the new plant in Mexico.

While production in Japan mainly focuses on motorcycles, the Mexico plant manufactures larger, design-oriented products such as ATVs and personal watercraft (PWC).

As a result, the introduction of hydrographic transfer—a process directly linked to appearance quality—was considered for the painting line.

The person responsible for painting-related technologies, including hydrographic transfer and FRP design, was Mr. Kei Kitada from the Advanced Technology Department.

Kitada explains:

“Our company has a growth vision toward 2030, and the launch of the Mexico plant is a key part of that. Painting, hydrographic transfer, and FRP design fall under my responsibility, and this project was a challenge for me as well.”

Hydrographic transfer was a technology Kitada had never worked with before.

Therefore, at the start of the project, he visited Kawasaki Motors Manufacturing Corp., U.S.A. (KMM) in the United States and spent one to two months learning technical know-how on-site.

“The hands-on training at KMM was extremely valuable. Experiencing the hydrographic transfer process and quality control on an actual line gave me a clear image of what was needed for the Mexico launch.”

Kitada’s technical perspective and on-site experience became the driving force behind this unprecedented challenge of automating the hydrographic transfer process.

What is Hydrographic Transfer? — Technology for Applying Patterns to Curved Surfaces

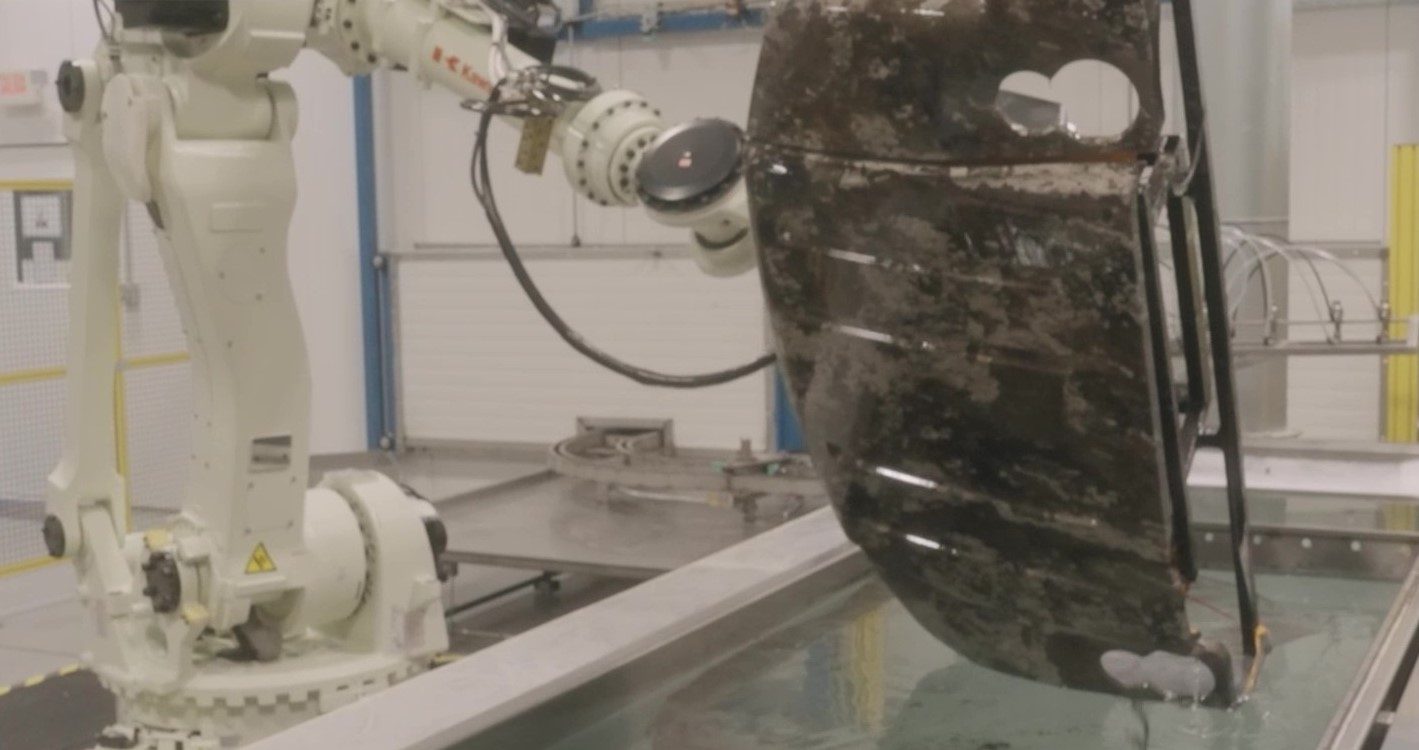

Hydrographic transfer is a technique that floats a printed film on water and transfers its pattern onto the product’s surface.

This process is not just painting—it enables uniform pattern application on three-dimensional shapes and complex curves, making it ideal for design-focused products.

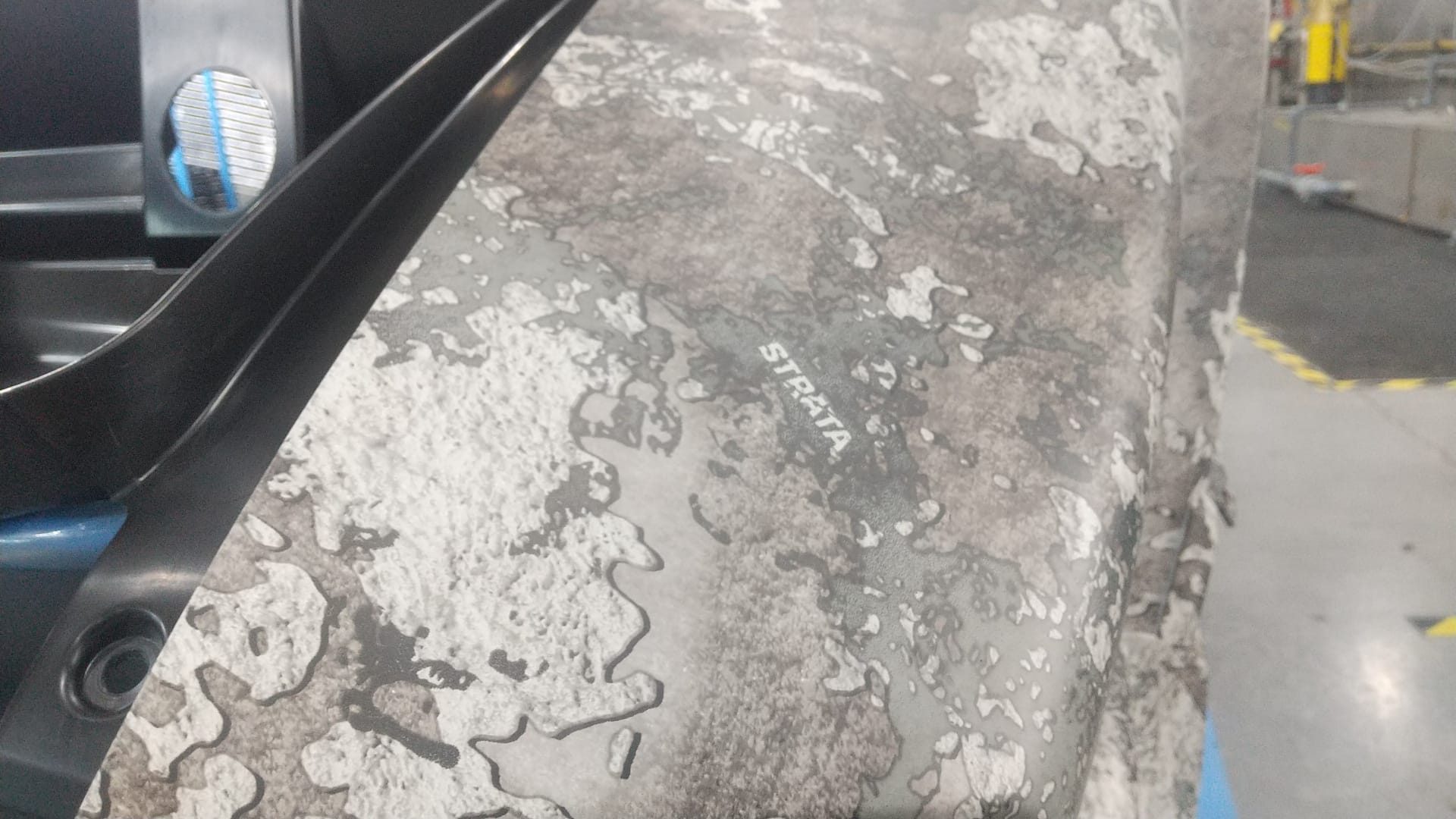

In this project, high-precision transfer was required to achieve camouflage patterns, which are in high demand in the Mexican market.

Camouflage patterns have complex, blurred color boundaries, so precise control of application pressure, angle, and speed is essential for a uniform finish.

However, at Kawasaki’s Akashi plant in Japan, there were almost no examples of automated hydrographic transfer. This project was a technical challenge for both Kawasaki Heavy Industries’ Robot Division and IEC, which handled robot system integration.

Manual hydrographic transfer heavily depends on operator skill, often resulting in pattern misalignment or uneven film thickness.

To ensure stable quality at mass-production levels, precise robotic motion control and painting system integration were indispensable.

IEC’s Challenge — A “Never Say No” Spirit and On-Site Capability

The painting system for the hydrographic transfer process was handled by IEC, a robot system integrator (SIer) with expertise in painting equipment design and installation, as well as strong capabilities in robot integration and a proven track record with Kawasaki robots.

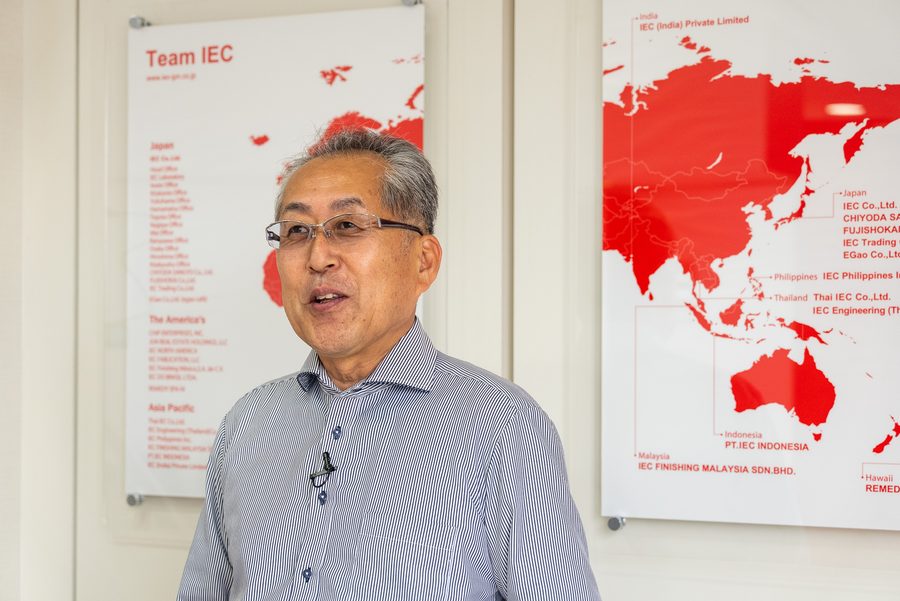

Mr. Kazuhiro Takeda, Director of IEC’s Osaka Sales Office, recalls:

“IEC is also a robot integrator, so we were approached with the expectation that ‘IEC can do it.’ Since we also handle automated machines, we earned their trust.”

In fact, IEC had no prior experience with hydrographic transfer, making this their first attempt.

Nevertheless, Takeda emphasizes IEC’s corporate culture of “basically never saying no,” and their determination to take on unknown technical fields.

“Even though hydrographic transfer was unprecedented for us and there were doubts internally about whether we could do it, we decided to proceed with strong internal support and help from partner companies.”

IEC leveraged not only technical expertise but also on-site adaptability and a culture of challenge to drive the project forward in collaboration with Kawasaki Heavy Industries’ Robot Division.

Despite the high difficulty of launching a process at an overseas site, they delivered with trust and execution power.

On-Site Trials and Technical Challenges

Hydrographic transfer involves more than just applying a film. IEC cites film activation as the most difficult part of the process.

“Activating the film by dissolving it with solvent required extremely precise adjustments of application amount and speed. Robot teaching was also challenging—too fast or too slow would ruin the film thickness. We repeated countless trials and errors on-site to find optimal conditions. This project truly tested our adaptability.”

Selecting the right robot and handling on-site troubleshooting were also tough, but thanks to Kawasaki Robot Division’s quick support, they met the deadline.

These steady efforts were key to successfully launching an automated hydrographic transfer process with no prior track record.

Looking Ahead — Delivery Is Not the End

This project was not just about installing equipment.

For IEC, it was their first hydrographic transfer project, yet they demonstrated strong technical and on-site capabilities, successfully launching the process at the Mexico plant in collaboration with Kawasaki Robot Division.

Following this success, IEC clearly states their commitment:

“We opened a new office in Monterrey, Mexico this year to strengthen local after-sales support. We aim to stay close to the site through maintenance and build lasting trust with our customers.”

This approach is highly valued by Kitada of Kawasaki Motors:

“Hydrographic transfer was an unknown process for us, but IEC’s ‘never say no’ attitude gave us confidence to entrust them. Their ability to respond quickly to issues was extremely reassuring.”

Providing ongoing support and immediate response to challenges—this “partner-style” technical assistance is the foundation of trust in manufacturing and will remain crucial for global expansion.

Conclusion

This hydrographic transfer automation project was a collaborative effort by IEC, Kawasaki Heavy Industries’ Robot Division, and Kawasaki Motors, Ltd., tackling an unprecedented technical domain.

By combining their expertise and on-site capabilities, they achieved a high-quality, stable production system at the new Mexico plant.

IEC comments on the future of manufacturing:

“As automation advances in the age of AI, IEC must strengthen its technical and sales capabilities accordingly. We also focus on product development that meets customer needs by sharing feedback internally and working closely with our development team.”

Meanwhile, Kawasaki Motors plans to further increase production of core products such as PWCs at the Mexico plant.

To achieve this, improving productivity across all processes, including FRP, is essential—and the success of hydrographic transfer automation marks the first step.

This project was not just equipment installation—it was a result of collaboration built on technology and trust.

Its success will serve as a solid foundation for future global expansion and the evolution of manufacturing.