Kawasaki Robotics, driven by its purpose “Unlocking human ingenuity to create robotics that enrich the future” has long pursued the development of technologies that enable robots and people to coexist. The ultimate form of this coexistence is the humanoid robot—capable of moving on two legs and performing tasks with two arms, giving it the versatility necessary to take on work traditionally done by humans.

This article introduces the lineage of Kawasaki’s humanoid robots, from the first prototype to the eighth generation.

Origins of Kawasaki’s Humanoid Development

Kawasaki, the company that built Japan’s first industrial robot, has long led the field of industrial robotics for factory production lines. Drawing on more than half a century of experience in developing and manufacturing industrial robots, Kawasaki has also expanded into human‑centric robotics—creating systems that provide value outside traditional factory cells. These include the duAro dual-arm collaborative robot, designed to work safely beside humans, and Successor, a remote‑cooperation system that removes the difficulty of conventional robot teaching.

As the ultimate extension of these efforts, Kawasaki is developing humanoid robots.

Because humanoids walk on two legs and perform tasks with two arms, they offer a high degree of freedom and the potential to take on work traditionally performed by humans.

2015 — The First Prototype

Kawasaki began developing humanoid robots around 2015. For a company that had long specialized in industrial robots, creating a robot capable of bipedal locomotion represented a major challenge.

To determine how to reproduce a human‑like form mechanically, the team first explored how motors and joint mechanisms should be arranged. However, the deeper we studied human anatomy, the more we realized just how complex and flexible the human body truly is. This led to a shift in design philosophy: instead of trying to replicate human motion directly, we extracted only the essential functions of the human body and recreated them using motors and mechanical structures. This conceptual shift ultimately enabled the realization of stable bipedal walking.

One of the biggest differences between industrial robots and humanoid robots is the load they must support. A typical industrial robot with a 100‑kg payload often weighs more than 600 kg and is designed to lift objects lighter than itself. In contrast, a humanoid must lift loads greater than its own body weight, making extreme weight reduction critically important.

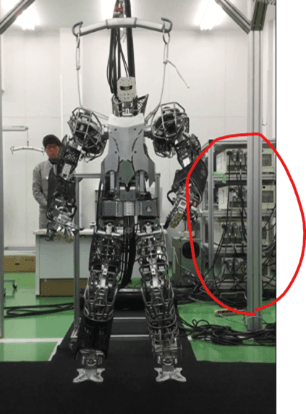

The first prototype had insufficient leg rigidity, and its knee mechanism in particular was vulnerable to torsion, resulting in unstable walking.

Up to the third prototype, those were used the E‑controller designed for industrial robots. However, it was large, had a control cycle too slow for humanoid applications, and required four separate units, which meant the controllers alone occupied a significant amount of space. These issues were later resolved by transitioning first to the F‑controller and eventually to a dedicated humanoid controller.

Falling poses the greatest risk to a humanoid robot, as it can lead to serious damage to the machine. To ensure the robot could withstand such incidents, we conducted repeated tests in which the robot was intentionally made to fall while performing controlled break‑fall motions.

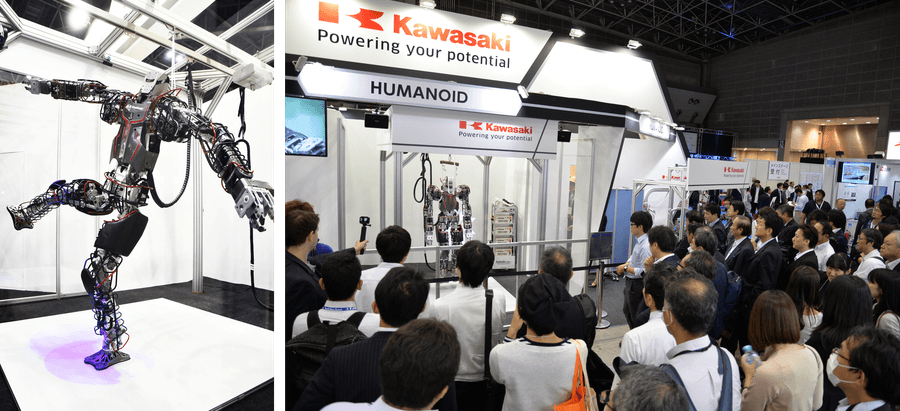

2017 — First Public Debut at iREX

Kawasaki publicly unveiled Kaleido at the 2017 International Robot Exhibition (iREX 2017), demonstrating actions such as stand‑up motions and pull‑ups.

- Height: 175 cm

- Weight: 85 kg

- Power: External tethered supply

The robot suffered issues until the eveniBehind the scenes:

The robot suffered issues until the evening before the exhibition, forcing the team to consider reducing the demo drastically.

A final round of adjustments worked, enabling a successful full demonstration on opening day.

Although switching to the F‑controller made the system somewhat more compact,

it still weighed about 30 kilograms—far too heavy to be mounted inside a humanoid robot.

2019 — Battery Integration and the Path to Lightweight Design

Kawasaki unveiled its first fully untethered bipedal walking demo with an onboard battery. At that time, Kaleido stood 178 cm tall and weighed 85 kg. While maintaining this weight, the team replaced the four external controllers with compact, high‑performance amplifiers and motor drivers, and integrated all electrical components into the robot’s body. By adopting an onboard battery as the power source, Kaleido achieved complete stand‑alone operation.

To realize stand‑alone operation without increasing the overall weight, numerous development efforts were undertaken. The first focus was the skeleton and exterior design. Magnesium alloy—lighter than aluminum—was used for structural components. Additionally, the metal‑frame exterior panels were replaced with 3D‑printed resin parts, resulting in significant weight reduction. Producing resin components in‑house also dramatically accelerated the prototyping cycle.

Beyond these major improvements, the team performed countless incremental weight‑saving refinements. At times, components became too fragile after being lightened, forcing the team to revert them to stronger, heavier versions. It was extremely difficult to predict where issues would arise, so the team repeatedly built, tested, and refined the design through persistent trial and error.

Walking Control Development and Custom Force Sensors

Once hardware reached maturity, the team began developing advanced gait control. Humanoids typically rely on 6‑axis force/torque sensors at the ankles, but commercial sensors were:

- Highly accurate

- Too heavy

- Expensive

- Susceptible to shock damage

For a humanoid performing steps, stomps, or jumps, lighter and shock‑resistant sensors were a necessity. Kawasaki therefore developed custom 6‑axis force/torque sensors optimized for humanoid walking.

2021 — Introduction of the “Friends”

Compared to the powerful and robust Kaleido, the Friends series focused on a slimmer, more approachable humanoid designed for tight spaces and potential future roles in caregiving and daily-life assistance.

A Friendly, Approachable Design

Friends was designed with soft, curved lines so it can blend naturally into human environments such as homes and care facilities. To create a friendly impression, the robot uses a display for its eyes, allowing it to express emotions in a human‑like way. The name “Friends” reflects the idea behind the project—a robot that can truly become a friend to people.

Conversational and Gesture Interaction

In collaboration with Osaka University’s Nagai Laboratory, we developed conversational and gesture‑based interaction capabilities. This was the first attempt of its kind among the humanoid robots we had created. Using AI, Friends generates spoken responses to questions posed by users. At the same time, it performs gestures synchronized with its replies, enabling more human‑like communication.

At an event held at the National Museum of Emerging Science and Innovation, Friends answered questions from children in the audience. Although the conversational quality was not perfect, the venue was packed, and the robot’s humorous interactions often drew laughter from the crowd.

2023 — Achieving Stable Walking

Kawasaki upgraded both software and hardware, adding real-time footstep adjustment to correct landing positions when balance is disturbed. This significantly reduced the risk of falling and improved robustness.

The Future of Humanoid Robot Development

Robots are expected to help people by taking on work that is dangerous, dirty, or physically demanding. However, robots are traditionally good at repeating tasks that have been pre‑taught, which makes it challenging for them to handle work that cannot be predicted in advance.

If humanoid robots can be operated remotely, they could take over hazardous tasks at dangerous sites, while operators remain safely in urban areas and control them from anywhere in the world. This capability is especially valuable in disaster‑response scenarios, where unstable terrain and the risk of secondary accidents make human entry extremely dangerous.

Kawasaki’s booth is dedicated to realizing a future where humanoid robots work right alongside you.