INCREASE PRODUCT QUALITY

WITH AUTOMATED MATERIAL REMOVAL

Automated material removal applications include polishing, grinding, trimming, cutting, and deburring to only name a few. These processes are challenging due to motion and positioning requirements, tool wear error, and force control. Kawasaki has developed software options to solve many of the challenges with material removal applications.

Kawasaki offers feedback control to apply the correct amount of force between the workpiece and the material removal equipment. Also offered is motion cooperation between multi-axis positioners and the robot to solve a variety of motion constraints during the material removal process. Kawasaki can provide custom material removal solutions to fit your specific application. The robot controller includes standard options for communicating with the material removal equipment.

Kawasaki can help your company achieve consistent product appearance and quality through automated material removal.

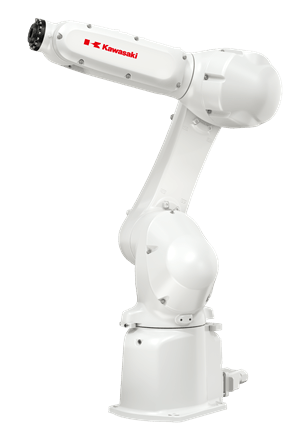

Robots for Material Removal

Small-to-medium robots up to 80kg payload

Small to medium-sized general-purpose robots with payload capacity from 3 to 80 kg.

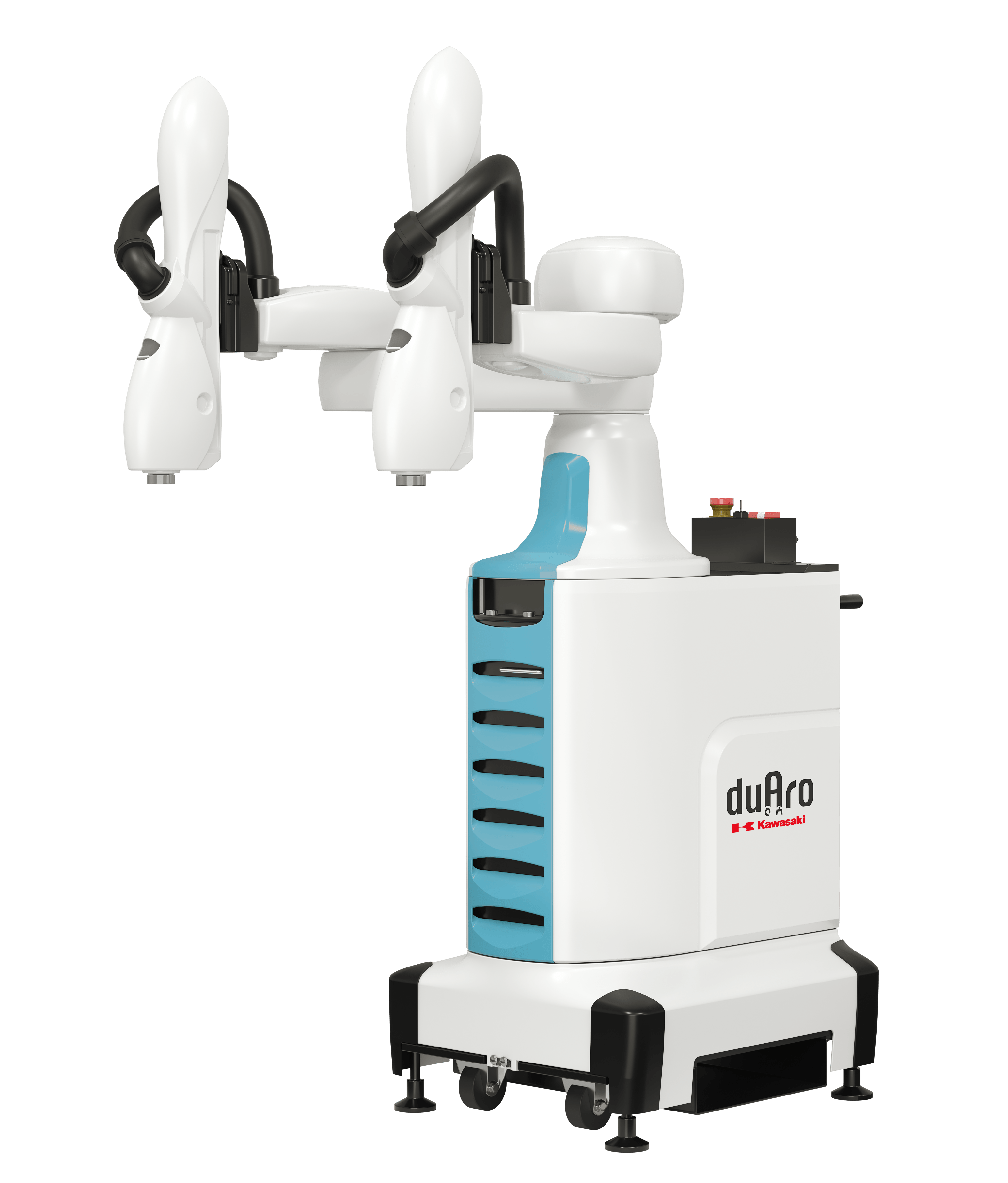

Dual-arm Collaborative robots

Kawasaki’s uniquely developed dual-armed SCARA robot can coexist and collaborate with humans.