4/6 Pages

About 70 years have passed since the birth of Astro Boy, the son of science. People have long dreamed of a future in which humanoid robots that look like them will become everybody’s friends. And now, in the industrial world, research and development of humanoid robots is accelerating. The day when the son of science coexists with human society may be approaching reality. How far have humanoid robots come and where are they going? Let’s follow their footsteps. Robots in a fantasy world In short, robots are defined differently in academic, industrial, and artistic worlds. In particular, it seems the robots that live in the world of science fiction are […]

Society has been expanding its expectations of the role robots play, looking at them to combat issues such as a declining population due to an aging society and frequently occurring natural disasters.Collaborative robots (cobots) are attracting the attention of industries—some can coexist and work in the same space as humans, and others cooperate with humans working on the same operations. With robots helping take over tasks physically demanding on humans, or supporting humans in an operation, new approaches in how humans and robots work together and new social systems are gradually appearing. Kawasaki Heavy Industries, or Kawasaki, whose robotics business has a history dating back over 50 years, is a […]

Imagine a future where humanoid robots are dispatched to disaster sites or play a key support role in elderly care. Although a scene from a science-fiction movie might spring to mind, many people may find it hard to imagine how robots would actually function in the real world. One company working in earnest to practicalize humanoid robots is Kawasaki Heavy Industries, or Kawasaki. Two years have passed since the company debuted its concept humanoid robot at the International Robot Exhibition (iREX) 2017. At iREX 2019, held at Tokyo Big Sight from December 18 to 21, 2019, Kawasaki unveiled Kaleido, an evolved version humanoid robot equipped for a role in real-world […]

duAro2 makes its debut In June 2018, a new model of the dual-arm SCARA robot “duAro” series, the duAro2, was released. The duAro is a collaborative robot (cobot) first launched by Kawasaki Heavy Industries, or Kawasaki, in June 2015. Like humans, it has two arms and is capable of working alongside humans in the same environment. While the series’ inaugural duAro1 model specializes in horizontal motion, the duAro2 improves upon its capabilities, extending the range of its arms’ vertical stroke from 15cm to 55cm, and increasing the maximum payload of each arm from 2kg to 3kg. Shogo Hasegawa (GM of FA Solution Second Department of Robot Business Division in Precision […]

The World Robot Summit Warm-Ups Get Underway The World Robot Summit 2018 (WRS2018), an international competition for robots, was held at the Tokyo Big Sight for 5 days from October 17 to 21, 2018. The World Robot Summit, or WRS, is a major event for robotics hosted by the Ministry of Economy, Trade and Industry, and the New Energy and Industrial Technology Development Organization (NEDO), with the goal of accelerating the social implementation of robots amidst a rapidly aging society, and the 2018 summit served as a precursor to the main competition (WRS2020) set to take place in 2020, the same year Japan will host the Tokyo Olympic and Paralympic […]

There are only two years to go until the opening of the 2020 Tokyo Olympic and Paralympic Games, and preparations are in full swing. There is also another big international event which will be held in Japan around the same time that should not be forgotten. That is an international robotics event, the World Robot Summit (WRS) which is hosted by the Ministry of Economy, Trade and Industry and the New Energy and Industrial Technology Development Organization (NEDO). Although various international robotics exhibitions have been organized, the WRS is the first international robotics exhibition organized by a nation. The WRS’s aim is “to promote a world where robots and humans […]

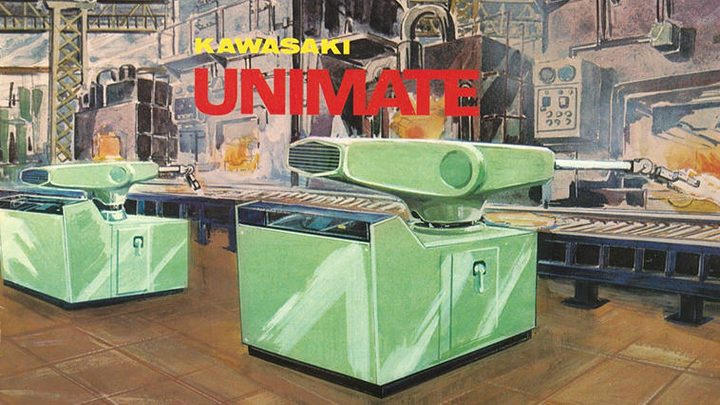

Another story of robots during the period of rapid economic growth In the 1960s, Japan was at a fever pitch with its dramatic economic growth. With the opening of the Tokyo Olympic Games not too far off, inaugurations of things like expressways and the Shinkansen (high-speed bullet train) were happening one after another and people were living increasingly enriched lives. At that time, Astro Boy, the wildly popular robot animation series, had just started its TV broadcast on the airwaves, bringing much excitement into living rooms all across Japan. For most Japanese people, robots were a source of inspiration and represented an image of the future. But behind the scenes, […]

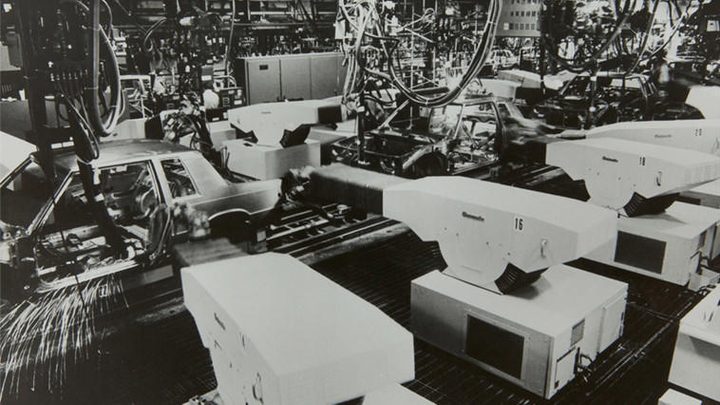

“Kawasaki-Unimate”, Japan’s first domestically manufactured industrial robot Industrial robots have strongly supported businesses in Japan. Although today it becomes common for many companies to implement robot systems, the road to widespread adoption was by no means a smooth one. As a matter of fact, the first industrial robot domestically manufactured in Japan was the Kawasaki-Unimate launched by Kawasaki Heavy Industries, or Kawasaki, in 1969. This article will introduce some of the stories behind the development of this home-grown Unimate. An industrial robot is a machine with multiple, freely-moveable, operable joints capable of performing tasks such as welding and handling heavy objects. Once movements are configured through teaching and programming, industrial […]

“Special training” required to use industrial robots Like driving schools, there are also robot schools. These robot schools deal with industrial robots such as robotic arms. Today, the use of collaborative robots (cobots) which work with humans in the same workspace is gradually increasing. Some of these cobots are made with materials that won’t hurt people if they come in contact with each other or are able to stop immediately when they sense a collision with humans. On the other hand, since industrial robots used at factories are extremely powerful and move at high speed, operation without proper training may cause serious accidents. To prevent such accidents, it is necessary […]

Are the structures of robots and humans the same? Robots and humans share a common feature. Humans and mechanical robots—as opposite as they may seem, they, in fact, share the same underlying structure of links (bones) and joints. The basic skeleton of industrial robots, of which is made up of mainly robotic arms, is a combination of links and joints. Relating it to a human body, parts that can freely bend and move about, such as the elbow and shoulder, are the joints, and the bones connecting those joints are equivalent to a robot’s links. The principle of moving joints and transmitting power through the links is common in both […]