- IndustriesLogistics

- ApplicationsPalletizing

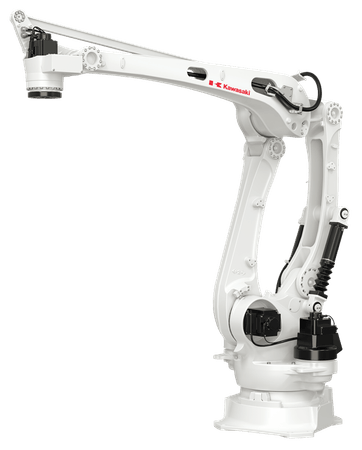

- Robot SeriesCP series

Kamigumi Corporation is a comprehensive logistics company that has supported port logistics in Japan since its birth in Kobe with the opening of the Port of Kobe. The company offers a wide range of services, starting from cargo handling at the port, warehousing, land transport, heavy cargo transport and overseas local logistics. Today, under the banner of ‘Kamigumi Design Logistics’, the company provides optimum logistics solutions for each customer.

At logistics sites, more advanced automation was required to improve work efficiency and safety and stabilise quality. Against this backdrop, Kamigumi introduced Kawasaki palletising and devanning robot ‘Vambo’ to realise a system that automates the entire process from container unloading to palletising.

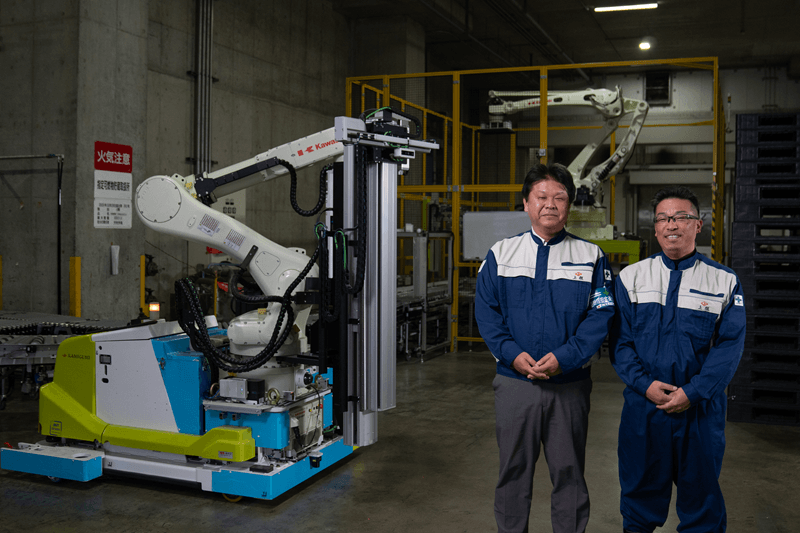

We spoke to Mr Matsuda, Deputy Branch Manager of the Kobe Branch, and Mr Nakamura, General Manager of the Warehouse Department, to find out more about this innovative initiative.

Automation study underway on Kobe’s Port Island

The stage for automation by robot is Port Island in Kobe, where Kamigumi handles import cargo as part of its port business among its multiple bases. Here, a series of processes are required to be carried out efficiently, from receiving containers arriving from overseas and unloading the cargo inside the containers to sorting and storing the cargo.

The series of operations targeted for automation

- Container receiving: containers delivered by truck are opened in the yard

- Unloading: workers manually unload approximately 25 kg of cardboard inside the container

- Palletising: unloaded cargo is stacked on pallets and secured with wrapping

- Preparing for storage and shipping: the goods are moved into the warehouse by forklift truck for storage or shipping.

These processes are important work that requires precision and speed, and improvement measures are being considered to create a more comfortable and safe environment for workers, says Matsuda, Deputy Branch Manager, Kobe Branch, about the situation at the time:

We were actively looking at new options, including robots, to make on-site work more efficient and safer. That’s when we came across Kawasaki Heavy Industries’ palletising robot and Vambo, a devanning robot that unloads containers.”

Why Kawasaki Heavy Industries?

The reason why Kamigumi chose Kawasaki Heavy Industries’ robots for this project was not just mechanical performance. The deciding factors were reliability, backed up by years of experience, and flexible customisation to meet the diverse needs of the logistics site.

Mr Matsuda explains.

Kawasaki’s long track record is what we were most looking forward to. The advanced technology and flexible customisation made it possible to handle a wide variety of tasks, which was also a big draw for us. In addition, the system’s high speed and precision, safety and ease of use, as well as the excellent support system after installation, made it suitable for long-term operation.”

One of Kawasaki’s strengths is its ability to offer integrated, automated solutions from debanning to palletising. The ability to build a system that does not simply provide a single robot, but focuses on the entire logistics site process, was of great value in this project.

This ‘one-stop automation proposal’ not only reduces the workload at the site, but also stabilises work efficiency and quality, and even paves the way for full automation in the future.

What was the on-site reaction when it came to automation with robots?

After much consideration, the automation project at the Kobe Port Island warehouse is now officially under way. This initiative is a major challenge for the logistics site, as it involves the introduction of a system that automates the entire process from container unloading (devanning) to palletising.

Mr Matsuda recalls the moment:

When I first saw the robot, I was surprised by its size. I was also worried: ‘Can such a big machine really work in a warehouse?’ I was also worried about whether such a big machine could really work in a warehouse. It was an unprecedented approach to have a robot handle everything from unloading containers to palletising at a warehouse site.”

Changes at the workplace after the introduction – not just manpower saving, but the challenge to improve the trinity of safety, efficiency and quality

How has the workplace changed since the introduction of the system? Mr Nakamura, Warehouse Department General Manager, who is in charge of day-to-day operations, explains.

In the past, unloading cargo from the top down in containers was relatively smooth, but lifting cargo from the bottom up was hard on the operator’s back. Now that this has been automated by robots, we feel that both efficiency and safety have improved. In particular, the fact that we no longer have to work in a hot environment in the summer has been very well received by the site, as it eliminates the risk of heat stroke.”

The robot now handles the most burdensome part of the work, which used to be carried out by four people, so the workers can concentrate on light work, according to the on-site staff,

Handling heavy loads has become easier.

The on-site staff have also commented that “handling heavy loads has become easier” and “work speed has increased and the overall flow has become smoother”.

The system has also received many positive comments from staff on site, such as “handling heavy loads has become easier” and “work speed has increased and the overall flow has become smoother”.

Although there were some issues in the early stages of the introduction, such as the time required to learn to operate the robots, they were generally very highly rated. In general, ‘manpower saving’ and ‘cost-effectiveness’ are often cited as reasons for introducing robots at logistics sites, but Kamigumi’s focus in this project was to ensure worker safety, and they were able to achieve this.

Future prospects: expectations for further improvements and full automation

This initiative was a major step forward in the field of logistics, automating everything from container unloading to palletising. However, the site is already looking ahead to the next stage.

Mr Nakamura says: “In the future, we will be able to automate a variety of tasks.

‘In the future, we hope to make improvements while sharing data with Kawasaki Heavy Industries as we perform various tasks, so that we can utilise robots in more processes. Ideally, we would like to see a complete automation of the entire sequence of work from the time the container enters the warehouse until it is palletised and stored in the warehouse.”

Furthermore, there are high hopes for the evolution of robots.

‘The more compact and faster they become, the more efficient they will be. We want to create better workplaces, while balancing safety and efficiency.”

As can be seen from these comments, the introduction of the new system is not the goal, but the first step towards full automation and further efficiency improvements. Kamigumi’s and Kawasaki’s efforts will continue as a challenge to open up the future of logistics workplaces.

Mr Matsuda (left) and Mr Nakamura (right), who were interviewed for this article.