- IndustriesMarine

- ApplicationsMaterial Handling

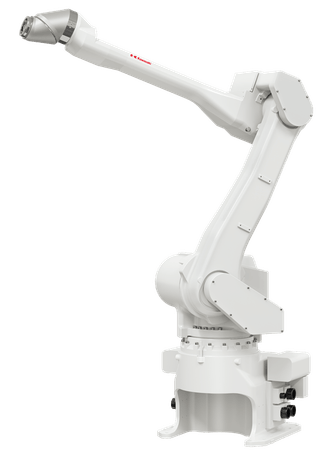

- Robot SeriesK series, BXP/BTP series

The manufacturing processes for FRP (fibre-reinforced plastic) products are difficult to standardise due to the characteristics of the material and the complexity of the shape, and rely on the experience of skilled workers in many situations. In particular, in processes such as spray-up and cutting, the intuition and manual skills of the operators determine the quality of the product, so the introduction of automation is accompanied by high technical hurdles.

This time, KADO and IEC have joined forces to automate the manufacturing process of Kawasaki Motors’ jet skis. Under the theme of “technology that can be used on the shop floor”, the two companies aimed to design a practical process that would meet the challenges of the shop floor, rather than simply replacing them. The challenge was to automate the customer’s factory using Kawasaki Heavy Industries’ robots.

Robotic automation is the key to bringing repeatability and mass production to processes that have long relied on onsite intuition and experience.

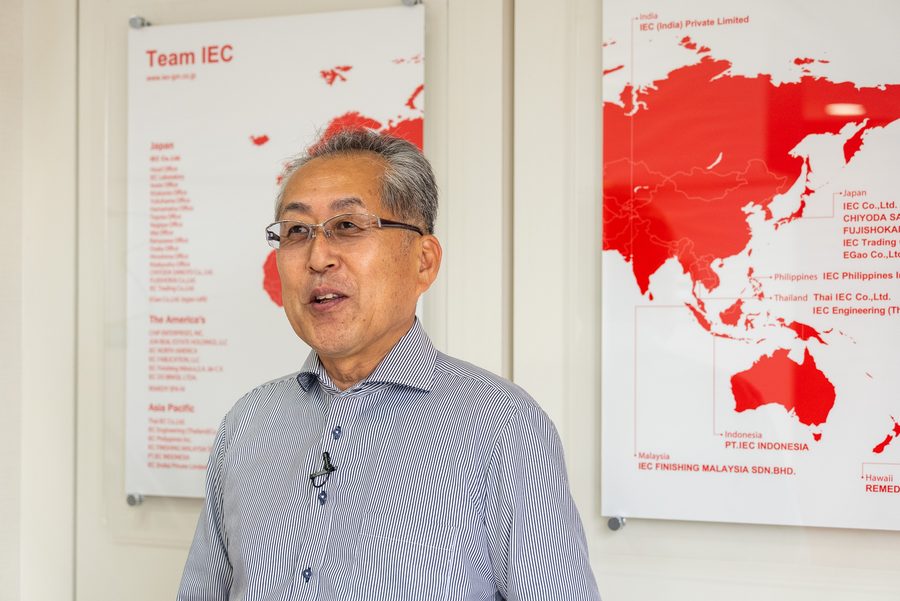

Through interviews with KADO’s President Kuratani and IEC’s Mr Takeda, this article describes how the two companies, in collaboration with Kawasaki Heavy Industries’ Robot Division, overcame on-site challenges and launched the automation of the FRP jet ski manufacturing process.

KADO x IEC: Materials and equipment, the power of both wheels on the shop floor

KADO Corporation was founded in 2000. The company originally started as a shipyard for racing yachts using CFRP (carbon fibre reinforced plastic). Since its inception, the company has conducted its own in-house research and development of FRP moulding technology and is particularly strong in composite moulding using high-performance materials such as CFRP and aramid fibres.

The company’s technical capabilities were recognised by an automobile manufacturer, who asked it to develop a moulding process, which triggered the company’s expansion into industrial applications: KADO began to undertake the design and development of entire manufacturing processes, rather than simply processing materials, and the need for automation technology gradually grew.

Mr Kuratani, President of KADO, says: “We did not start using robots because we wanted to, but because they were a natural choice as a means of stabilising our forming technology. In other words, automation using KADO’s robots was introduced as a result, not as an objective, and the choice of technology was born from the solution of problems on site.

IEC Corporation, whose core business is the construction of fluid transfer and circulation supply systems

IEC’s core business is liquid handling technology, and its strength lies in proposing systems that meet customer needs, making full use of robots, pumps and other equipment as well as coating machines. While focusing mainly on the automotive industry, in recent years the company has also entered the field of general industrial machinery.

Mr Takeda of IEC says that he was approached for this project because of his company’s strength in proposal-based sales, which led him to expect that IEC would be able to do it. In addition to the FRP spray-up process being similar in nature to painting, IEC is also a company with many overseas offices and could demonstrate its international capability in the factory automation project in Mexico.

Overcoming the barriers of the first challenge

Mr Takeda of IEC had the following to say about this automation project:

‘Automation of FRP weaving glass fibre was IEC’s first challenge, and we were determined to do it, so we combined KADO’s fibre forming technology with IEC’s equipment construction capabilities. We brought together the knowledge and experience of both companies and achieved the start-up through on-site cooperation.”

In automating the spray-up process this time, it was extremely difficult to make the glass fibre fibres follow the robot’s movements, and adjustments were repeatedly made over a period of two to three days to prevent them from being torn off. He says that the handling bracket and other parts were also improved through repeated trial and error on site with KADO.

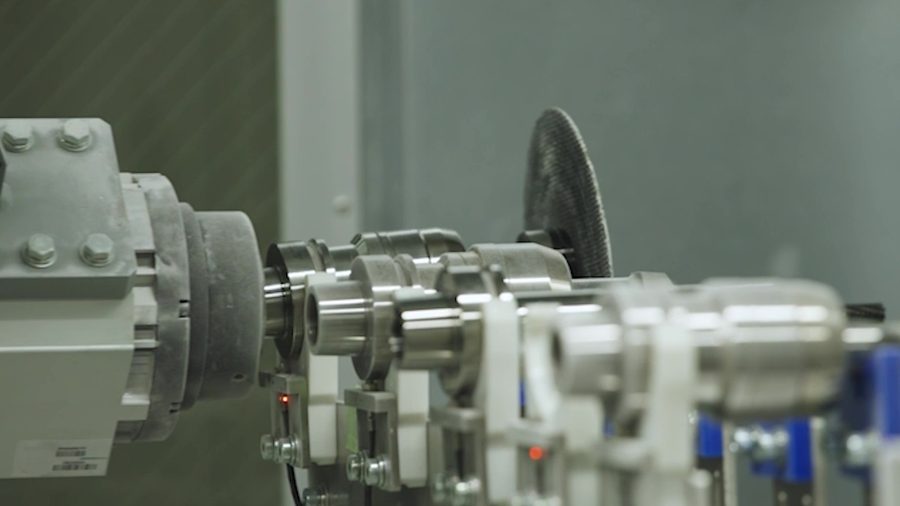

Automation in the FRP cutting process was not an easy path for KADO either. In particular, the complex material composition, with a mixture of gel-coat and GFRP layers, required the selection of the most suitable cutting tools and adjustment of cutting conditions, as well as dealing with the vibrations and load fluctuations that occur during machining.

President Kuratani says: “It was very difficult to incorporate the robot’s movements based on the senses developed through manual work. We made detailed adjustments to feed speeds and rotation speeds, while assessing changes in cutting resistance due to differences in materials”, he recalls.

Regarding the collaboration with Kawasaki Heavy Industries Robot Division, KADO President Kuratani says: “Kawasaki Heavy Industries robots have excellent rigidity and motion stability, and can be used with confidence even for materials with high processing loads, such as FRP. The technical support that helped us understand the design concept was very reassuring”.

Future-oriented use of FRP and prospects for both

FRP is lightweight, strong and corrosion-resistant, and its use is rapidly expanding in the aeronautics, space and mobility fields. In particular, the superiority of FRP as a structural material is attracting attention in next-generation mobile vehicles such as flying cars and drones, and the establishment of forming technology for future mass production is an urgent task.

KADO considers the digital management of the moulding process by robotics to be essential for these future product groups. The aim is to increase the reliability of FRP mass production by optimising processing conditions according to material characteristics and enabling quality tracing for each process.

IEC is also promoting the application of coating and handling technology to complex materials such as FRP, and intends to actively expand into fields other than automobiles in the future. Through the Mexico project, the company has also demonstrated its ability to respond globally by utilising its overseas bases, and this year it opened a new office in Monterrey to strengthen its local after-sales follow-up system.

Mr Takeda of IEC says: “It is important to stay close to our customers through maintenance and to continue our relationship of trust, rather than just delivering the product and calling it a day. In the future, we would like to take on challenges in an even wider range of areas, such as the space sector”.

Both companies are looking for new approaches to manufacturing that combine robot technology with field knowledge.

Conclusion.

KADO, which specialises in identifying on-site issues and designing processes, and IEC, which has strengths in dispensing and handling technology, worked closely with robot manufacturer Kawasaki Heavy Industries to provide a problem-solving technology proposal rooted in the workplace for this project.

The role of a SIer is not simply to connect technologies, but also to pick up feedback from the field and stand between the manufacturer and the user to build the optimum solution. In projects such as this one, where complex factors such as material characteristics, process design, robot control and overseas support are involved, the SIer’s integration skills are put to the test.

As AI and automation advance, SIers who can bridge on-site knowledge and technology are becoming increasingly important, and KADO’s and IEC’s work on this project is one example that can be used as a reference when considering the future of SIers.