3D vision

3D vision can recognize three-dimensional information, including depth and height, so it can handle complex tasks. Accurately determine the position of loosely stacked parts and tilted products and calculate the optimal gripping position. This allows for automatic picking of randomly stacked cases and workpieces with complex geometries, enabling advanced operations such as depalletizing and obstacle avoidance.

| Object Recognition | Shape, Depth, and Bulk Stacking Recognition |

| Position Correction | XYZ Coordinates and Tilt Correction |

| Picking | Bulk Stacking Picking |

| Robot Cooperation | Complex Movements and Obstacle Avoidance |

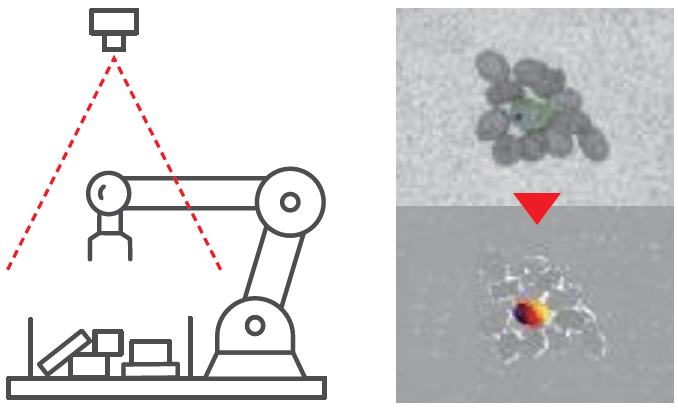

Object Recognition / Position Correction and Guidance Function

- Correction of X, Y, Z coordinates and tilt information

- Positioning of workpieces with height variations and inclinations

- Selection of the optimal gripping position for bulk picking

- Acquisition of depth information for three-dimensional shape recognition

- Recognition of loosely stacked parts (for picking applications)

- Identification of complex geometries and overlapping workpieces

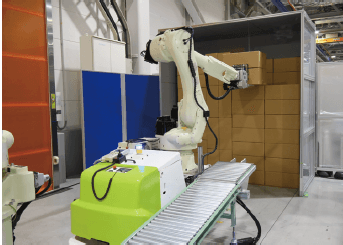

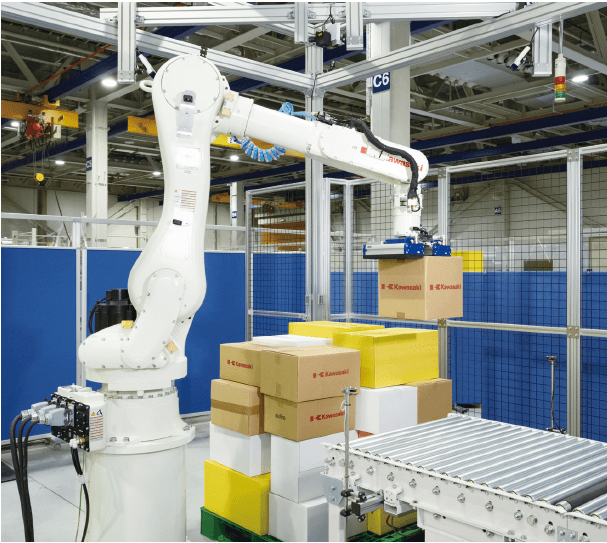

Picking / Depalletizing

- Picking of randomly arranged workpieces

- Depalletizing of boxes and bags(removal from stacked state)

- Avoiding obstacles during picking and placement

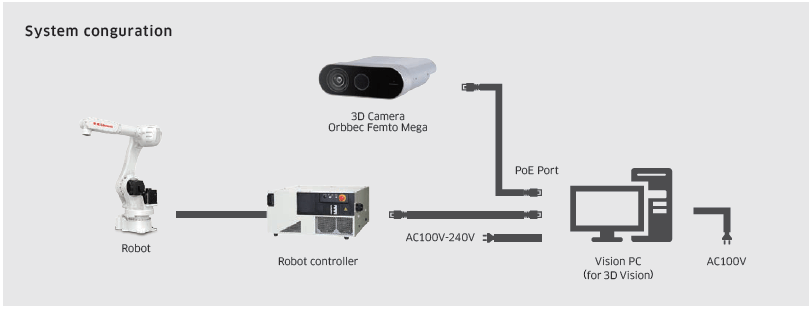

Kawasaki’s 2D vision system configuration

Case Study

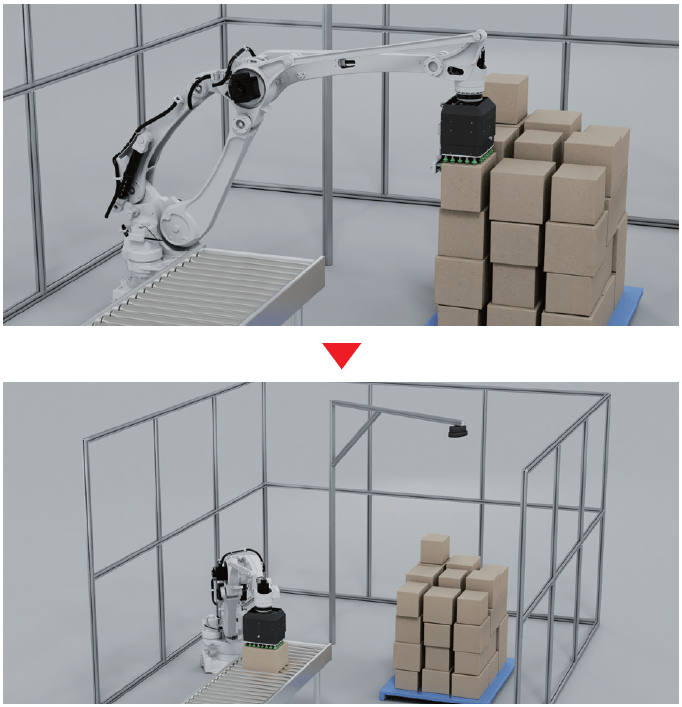

Decorating automation with K-VStereo

Kawasaki’s 3D AI vision system “K-VStereo” automates previously difficult devanning work by accurately recognizing cases in consolidated containers and grasping their position and posture. K-VStereo analyzes the shape and tilt of the case using a 3D camera and AI to calculate the optimal pick position in real time, so it can flexibly handle diagonally stacked cases and luggage of different sizes. This technology was used in the Vambo self-propelled devaning robot, which provides highly efficient unloading of up to 600 cases weighing up to 30 kg per hour. Vambo is a system that combines RS080N robots and AGVs to leverage K-VStereo’s recognition data to perform safe and secure picking even in narrow consoles. In addition, it can be operated with can be operated easily without the need for programming, greatly reducing the burden on the site.