– Achieving High-Speed Scanning Visual Inspection for Complex Curved Surfaces –

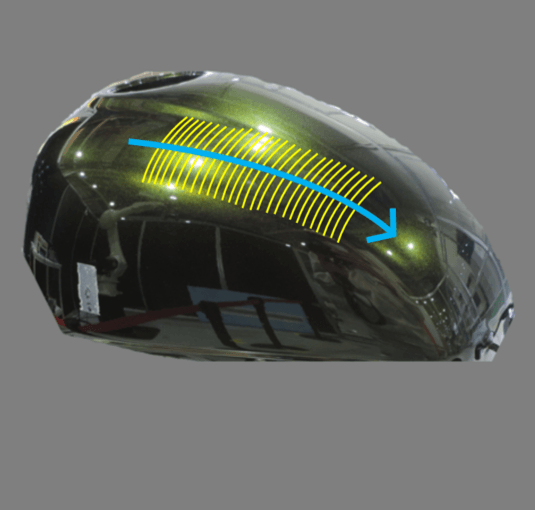

Kawasaki Heavy Industries., Ltd. has developed and started selling an Visual Inspection robot system that performs high-speed Visual Inspections of complex curved surfaces. The newly developed “High-Speed Pulse Output Function” technology enables high-speed Visual Inspection of products with complex curved surfaces by equipping the robot’s hand with a line camera.

In manufacturing sites, most of the Visual Inspections of products with complex curved surfaces, such as scratches, foreign objects, and uneven surfaces, are performed visually by humans. This has led to chronic shortages of skilled inspectors, inspection errors due to prolonged visual inspections, and the inability to ensure traceability, increasing the need for automated Visual Inspections.

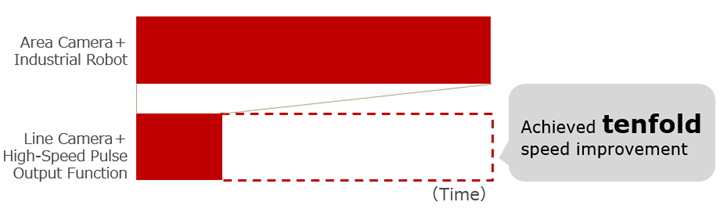

When using area cameras for Visual Inspections of curved surfaces, the imaging area is subdivided and intermittently imaged, resulting in longer inspection times.

By combining the newly developed “High-Speed Pulse Output Function” with a line camera capable of scanning imaging, high-speed continuous imaging along curved surfaces has been achieved. Even during high-speed robot movement at 1,000 mm/s, pulse output at 0.1 mm intervals (constant distance intervals) is possible.

By using the line camera in combination, inspection time is significantly reduced.

As an example, we conducted an application test combining our robot with the curved surface inspection line camera from Dexis Corporation, which has extensive experience with inspection cameras. Dexis Corporation’s line camera has a unique curved surface image capture function (Dynamic Tracing), enabling imaging of two-directional curved surfaces when combined with robot scanning. By utilizing our high-speed pulse output function to build a scanning inspection system, the speed of scanning inspection for complex curved surfaces can be increased by approximately ten times compared to conventional methods.

We will continue to provide solutions utilizing robots to address issues in the inspection field, such as labor shortages and stabilization of inspection quality.

*Note: Depending on the equipment and imaging conditions used.*