Successor

1/1 Pages

The growing issue of workforce shortages Currently, Japan is on the verge of becoming an aging society with a low birthrate, unlike any other in the world. The total population of Japan peaked in 2008, amounting to 128.08 million people, but has since been on the decline at a rate of approximately 100,000 people per year. According to the “Population Projections for Japan: 2016 to 2065” conducted by the National Institute of Population and Social Security Research in Japan (IPSS), the population is projected to fall below 100 million by the year 2053. The results of these projections have led to concerns about the growing issue of workforce shortages. In […]

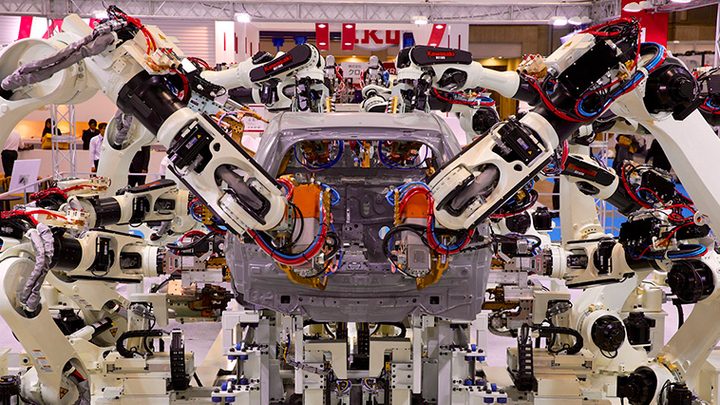

The International Robot Exhibition 2017 (iREX2017) was held at Tokyo Big Sight from November 29 to December 2, 2017. The massive venue housed numerous robots not only from all over Japan but also from the entire globe! The majority of the robots were single-arm or dual-arm industrial robots, but there were a few humanoid robots exhibited. It was like a scene from sci-fi anime in a real life! Of the many booths, the one from Kawasaki Heavy Industries, or Kawasaki, attracted many visitors who were gazing at each of the models with keen interest. Kawasaki exhibited humanoid robots to mark the 50th anniversary in their history of robotics business this year. The company has mainly focused […]

Advanced manufacturing technologies and skills: they make a cornerstone of a country. Due to the aging society, skill transfer of expert technicians who are responsible for these advancements may be at risk in the near future ———— Currently, many companies in the manufacturing industry are raising a red flag to this problem. And it is a problem not only for Japan but for many developed countries treading on the border of the 100-year-life era. In this light, a new robot system that shows promise in solving the problem of skill transfer has been unveiled. Kawasaki put on display its new robot system during the International Robot Exhibition (iREX) 2017 (Nov. […]

The obstacles in robot automation Recently, industrial robots have been working for various tasks previously performed by humans. An example is the spot-welding robots found in automobile factories that melt and attach separate steel plate parts together with heat. Yet, obstacles still exist to achieve automation by robots; did you know that in the manufacturing industry, most of the work is still accomplished by humans and only about 3% (※1) is conducted by robots? In order to deploy robots in manufacturing processes, it is necessary to instruct them beforehand through the process of programming. An engineer with expertise in robot programming specifies each movement, and only then can it be […]