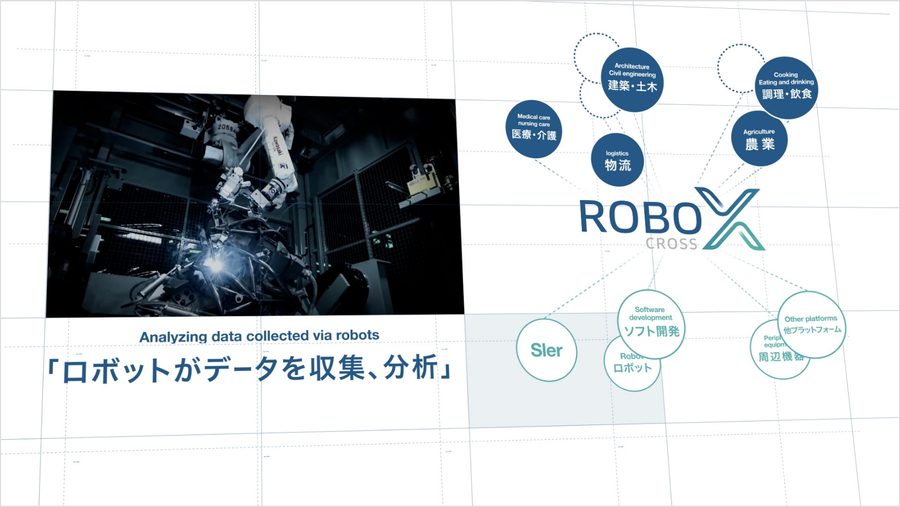

The robotics business of Kawasaki Heavy Industries has proposed automation and labor-saving solutions mainly for the manufacturing industry. On the other hand, there are still many social issues in the world. How can robots help to solve these social problems?

Kawasaki will cooperate with companies that are familiar with various issues and will work to expand the scope of robot utilization and to contribute to the solution of social issues through the utilization of the data collected by robots. The platform concept to realize this is the Kawasaki Robot Digital Platform, ROBO CROSS.

What is ROBO CROSS?

“An open development environment for the efficient creation of robot systems” , “A data utilization base to create value from the data collected by robots” It is a platform with two functions.

Improvement of robot system integration efficiency

Data retrieval

Sharing of reference data for robots, peripheral equipment, and system design

Virtual commissioning

Constructions of robot systems in digital space and perform verification under various conditions

Reflection in the actual system

- Download of the data after the virtual commissioning to the actual machine to shorten the time for start-up adjustments

We provide an environment where various data related to robots can be shared, and robot systems can be developed efficiently in the digital space. We will prepare convenient functions to make it possible for the systems developed here to be transferred without alteration to the actual machine.

Each partner develops an application in their area of expertise, and the resulting technology (software and hardware) is accumulated on the platform.

The mechanism is such that the more partners there are that participate in this platform, the stronger it becomes.

Creation of new value through data utilization

- Collection of data on the robot work status and surrounding environment

- Also collaboration with other platforms

- Utilization of data for the continuous evolution of robot systems and for the improvement of overall efficiency

If a robot becomes a sensor and collects data, we hope that not only will this make it possible to improve robot systems and the processes before and after them, but also to go on to create new original value for our users.

For the realization of ROBO CROSS

Kawasaki has launched a number of initiatives to make a robot digital platform a reality.

K-AddOn

To facilitate the connection between robots and peripheral equipment, we collaborate with equipment manufacturers to provide manuals, software and application examples.

Point

- Kawasaki conducts everything up to the connection checks

- No need to design parts or software for the connection

- Checking the usage method in application videos

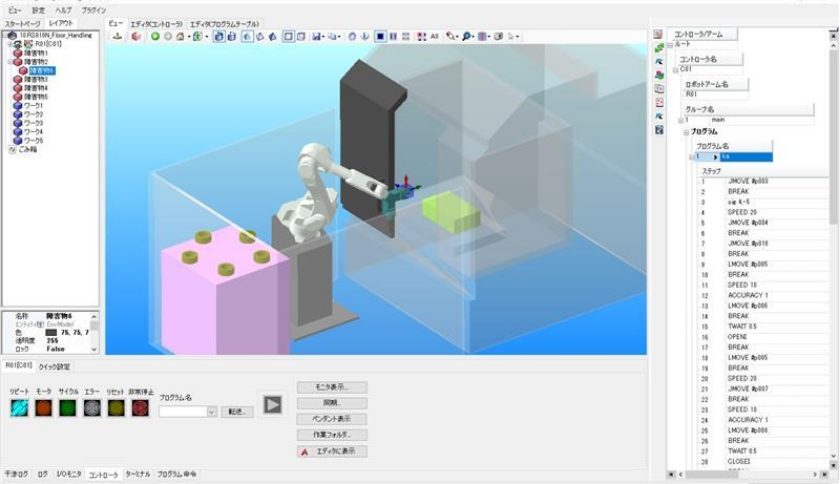

OLP

This is a tool to create a robot teaching program and check its operation in a simulation environment on a PC. This can shorten the time required for robot teaching in the field.

Point

- Accurate motion trajectory and cycle time are reproduced by simulation

- Interference checking, layout verification, and motion verification on multiple robots

- Teaching along complex workpiece shapes is also easy

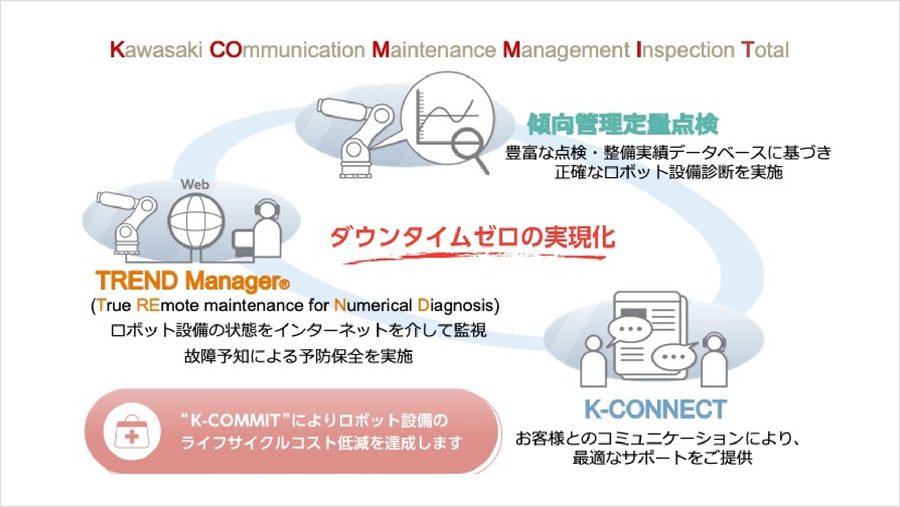

K-COMMIT Kawasaki Robot ANSHIN Lifecycle Support

An accurate and economical maintenance package that consistently implements inspections, management, analysis, proposals, and maintenance for zero downtime. We propose the optimal maintenance plan for the robot operation, and contribute to minimize the lifecycle costs.

Point

- The TREND Manager (predictive maintenance tool) reduces robot downtime

- Trend management quantitative inspections (quantification of inspection results) produce accurate notification of the status of the robot

- Strengthening of the relationship with users of the K-CONNECT (communication tool)

関連リンク

- ROBO CROSS

- 【ROBO CROSS】ROBO CROSSが実現する「ロボットのある未来」