5/19 Pages

Kawasaki’s investment helps GMS create financial opportunities for tricycle drivers so they can pay for education or new machinery, and take steps to become financially independent. Learn more…

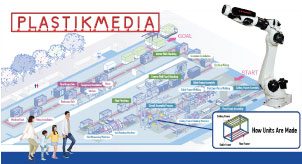

Kawasaki large payload robots assemble and weld structural beams and critical joints for this modular home manufacturer, helping them minimize their reliance on human labor in the midst of a labor shortage…

After their first Kawasaki robot completed 10,794,000 cycles, Metsä Wood installed a new Kawasaki CP180L palletizer to handle roughly 1,000 25kg bales per day. Learn why Kawasaki is the company’s first choice…

The Kawasaki Training Center has made some of their most popular courses accessible from any location using a robust online training platform. Email Training@kri-us.com for more information… (PDF:2.6M )

In this unique edition of KTV, hosts Johanna and Leith discuss what our company is doing to stay safe and prevent the spread of COVID-19, as well as the many Kawasaki resources still available during this time…

“In order to stay safe and do our part to prevent the spread of the COVID-19 virus, we are following our Michigan state government’s “”Stay Home, Stay Safe”” executive order, and advising all non-essential team members to work remotely until at least April 13, 2020. Read our full statement..

(PDF:310.6K

)”

In addition to arc welding robots, Kawasaki has arc welding packages that allow you to interface any welding power supply to the robot without modifying software…

To eliminate delays caused by inconsistent labor, this customer automated their end-of-line packing process with a customized high-speed packing cell from MWES Engineering and Kawasaki Robotics… (PDF:235.3K )

In this mulch palletizing solution from Nova Automation, a Kawasaki CP series palletizer allowed the customer to double production capabilities…

This automated palletizing solution, integrated by Caxton Mark Inc, allowed a Canadian farm increase production while eliminating an ergonomically challenging task for employees…