1/19 Pages

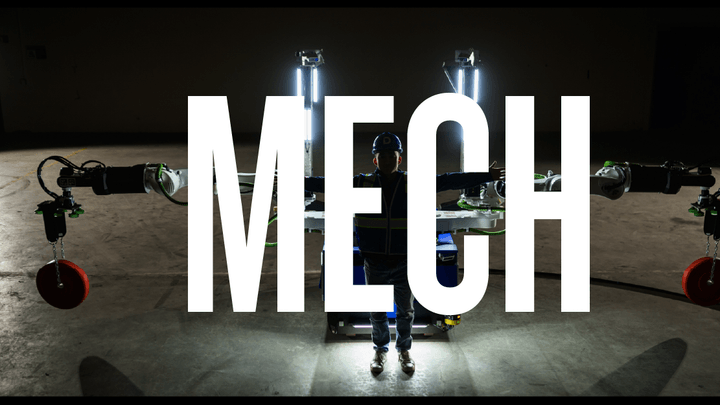

Redwood City, CA – May 08, 2025 – Dexterity, a global leader in physical AI and robotics, today announced a strategic partnership with Kawasaki Heavy Industries, Ltd., a global lead in robotic arm manufacturing, to produce high-performance robot arms for Dexterity’s hardware platform: the Mech. The Mech is a roving, two-armed robot designed from the ground up to embody Physical AI in industrial applications. Its roving base enables it to go where large enterprises need heavy lifting of a wide range of goods, and its lightweight but powerful, dual arm design enables it to pick and pack goods at the speed of operations—and beyond. Kawasaki’s expertise in precision engineering has […]

Kawasaki Develops Robotic Arm for Dexterity, a U.S. Unicorn Company – Installed on “Mech,” the World’s First AI Vanning Robot for Logistics Sector

Kawasaki Robotics will demonstrate new additions to its extensive robotics portfolio, including the new CL Series of intelligent collaborative robots (cobots), at…..

At a fraction of the cost of other educational robot platforms, Astorino equips students with the foundational skills needed for modern manufacturing…

Hurco announces strategic collaboration with Kawasaki Robotics to deliver turnkey, industrial-grade, robotic machine-tending solutions at IMTS 2024…

Kawasaki Robotics Shares First Look of New Collaborative Robots, Features New Partnerships and Applications for Industrial Robots at AUTOMATE 2024…

Kawasaki Robotics’ dedication to continuous improvement is evident in their technically advanced general purpose robot line: the R series. With a history dating…

Kawasaki Robotics’ dedication to continuous improvement is evident in their technically advanced general purpose robot line: the R series. With a history dating…

Kawasaki Robotics will be at Booth N-5946 at PACK EXPO International, which will be in Chicago from Oct. 23 to 26, 2022. Learn what they will be showcasing during the event…