2/18 Pages

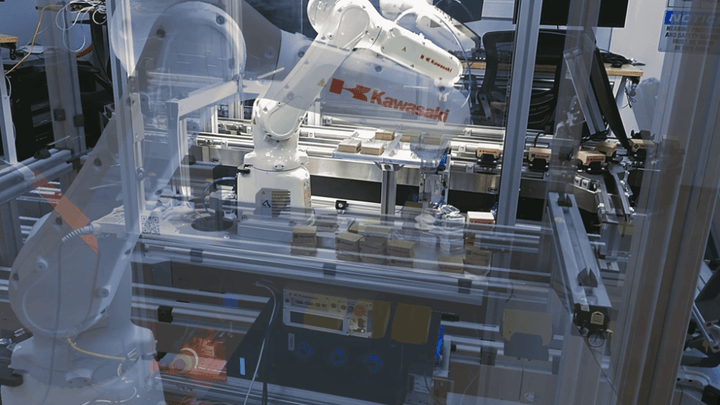

On May 24, Kawasaki Heavy Industries, Ltd. unveiled the “Kawasaki DX” project at Microsoft’s annual Build conference. Kawasaki’s DX initiative utilizes Microsoft’s industrial metaverse technology to implement a real time, virtual approach to robot care and maintenance.

Kawasaki Robotics is pleased to announce they are one of the recipients of Applied Materials’ 2022 Supplier Excellence Awards for Best in Class Performance. The awards reflect outstanding technical and operational performance in several areas including quality, service, lead time, delivery, cost and responsiveness.

Material handling has always been a Kawasaki sweet spot, and our robust robot lineup is a testament to that. Visit booth C3785 at MODEX 2022 to experience material handling solutions developed to streamline warehousing and distribution processes.

2022/03/22 iREX2022 (International Robot Exhibition ) iREX2022 (International Robot Exhibition) was held at the Tokyo Big Sight from March 9 to 11 Kawasaki took part in the exhibition and showcased latest robot technologies with the themes of “Safe and Secure Remote Society” and “Near Future MobilityDespite the COVID 19 many people visited our booth every day Thank you for your visit and interest in Kawasaki The following are partial photos of our exhibits. You can see our exhibits at our special iREX2022 site.

Kawasaki robots cut Ossenberg’s pipe processing times by over four minutes and boosted production volume to over 10,000 parts per day. Learn more about the cell in the latest edition of Modern Machine Shop…

Learn how Harbour Technologies’ Kawasaki robotic PPE cell helped frontline workers during the COVID-19 pandemic in this feature from Design World magazine.

For more than two decades, Kawasaki Motors used their flexible Kawasaki robot to weld different motorcycles as their product line evolved.

Mid-pandemic, Harbour Technologies pivoted their business model to manufacture PPE using a Kawasaki robot cell. Learn how this helped frontline workers, and allowed Harbour Technologies to expand their business.

“This end-of-line solution that can palletize at least 20 bags per minute in factory temperatures of more than 100°F. The end user’s outdated machinery was causing frequent downtime, so Conveying Industries updated their line with a brand new Kawasaki CP180L robot…

(PDF:204.7K

)”

On June 28, 2021, Kawasaki Robotics (USA), Inc. broke ground on the new addition to their Wixom, MI facility, which serves as the company’s North American headquarters and Training Center. ..