10/19 Pages

In epsiode 2 of the “Doing with duAro” miniseries, hosts Johanna and Leith explain why the duAro dual-arm collaborative robot is ideal for machine tending applications…

Dan Hasley, Kawasaki Robotics Director of Sales, walks ENGINEERING.COM through the design and benefits of Kawasaki’s high-speed, small-footprint deburring cell, which uses the new Kawasaki small payload RS007N robot running on the industry’s smallest controller…

Connect to your potential with KTV – a monthly news show to help you keep up to date on Kawasaki Robotics news, technologies and product developments…

Kawasaki R series robots helped this manufacturer eliminate part inconsistencies, efficiently weld a variety of parts and minimize their reliance on manual welding during a labor shortage… (PDF:165.9K )

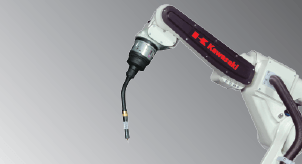

Kawasaki’s BA006L arc welding robot, built with a hollow arm structure, state-of-the-art technology and adaptive welding functionality, was featured in this month’s issue of The Fabricator… (PDF:441.0K )

Check out this video of one of the robot exhibits we are featuring at FABTECH 2018 – arc welding using a 700 kg payload half-arm positioner made from a MX700N robot, machine load/unload of the part to the positioner, and grinding of the welded part…

Learn how the Kawasaki duAro dual-arm SCARA robot facilitates human-robot collaboration and pioneered robot applications in areas that were previously deemed unfeasible…