9/18 Pages

Check out the results of the World Robot Challenge, which took place at the World Robot Summit in Tokyo October 17 to 21, 2018. More than 100 teams from 23 different countries competed in categories such as industrial robots…

“By automating their six-station COS (cast-on strap) process for making industrial lead-acid batteries, Battery Builders increased throughput, improved product quality, and lowered the number of operators needed…

(PDF:226.5K

)”

In epsiode 2 of the “Doing with duAro” miniseries, hosts Johanna and Leith explain why the duAro dual-arm collaborative robot is ideal for machine tending applications…

Dan Hasley, Kawasaki Robotics Director of Sales, walks ENGINEERING.COM through the design and benefits of Kawasaki’s high-speed, small-footprint deburring cell, which uses the new Kawasaki small payload RS007N robot running on the industry’s smallest controller…

Connect to your potential with KTV – a monthly news show to help you keep up to date on Kawasaki Robotics news, technologies and product developments…

Kawasaki R series robots helped this manufacturer eliminate part inconsistencies, efficiently weld a variety of parts and minimize their reliance on manual welding during a labor shortage… (PDF:165.9K )

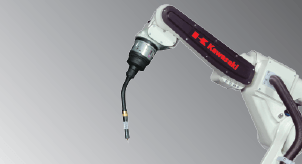

Kawasaki’s BA006L arc welding robot, built with a hollow arm structure, state-of-the-art technology and adaptive welding functionality, was featured in this month’s issue of The Fabricator… (PDF:441.0K )

Check out this video of one of the robot exhibits we are featuring at FABTECH 2018 – arc welding using a 700 kg payload half-arm positioner made from a MX700N robot, machine load/unload of the part to the positioner, and grinding of the welded part…