9/19 Pages

Couldn’t make it to Automate 2019? Don’t worry! KTV hosts Johanna and Leith walk you through the Kawasaki booth where several applications are showcased, including high-speed palletizing and packing using the RS007L robot’s overdrive feature…

In part four of the “Doing with duAro” miniseries, hosts Johanna and Leith unveil the brand new addition to Kawasaki’s line of collaborative dual-arm robots and discuss its new design features…

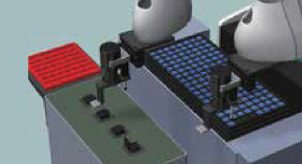

The new duAro2 cobot runs on Kawasaki’s compact F61 controller, which offers integrated 2D vision capabilities and comes standard with the duAro2. The vision software supports multiple pattern registration, with results viewable on the robot’s tablet…

Kawasaki’s collaborative dual-arm robot, duAro, keeps evolving. Learn more about the development of the NEW duAro2, and how Kawasaki plans to continue the advancement of their line of cobots…

Learn more about the newest additions to Kawasaki’s line of small-to-medium payload, general purpose R series robots, which offer the fastest operating speeds in their class…

After installing a Kawasaki CP180L high speed palletizing robot, Cecelia Farms was able to increase throughput while avoiding labor costs, and the robot’s extended reach allowed them to achieve tall pallet heights… (PDF:171.3K )

Learn what features make the duAro collaborative robot ideal for a variety of assembly applications in episode 3 of the “Doing with duAro” miniseries…

Check out the results of the World Robot Challenge, which took place at the World Robot Summit in Tokyo October 17 to 21, 2018. More than 100 teams from 23 different countries competed in categories such as industrial robots…

“By automating their six-station COS (cast-on strap) process for making industrial lead-acid batteries, Battery Builders increased throughput, improved product quality, and lowered the number of operators needed…

(PDF:226.5K

)”