6/19 Pages

In this festive episode of KTV, hosts Johanna and Leith recap the advancements Kawasaki Robotics made in the last year, including the launch of two new robot…

Kawasaki Robotics wishes you and your loved ones a loving and joy-filled holiday season, and a wonderful start to the upcoming year…

Kawasaki Robotics is proud to announce the company received with two awards at the 2019 Best of MichBusiness Awards; one in the “Technology Guru” category, and the other in the “Large Overall Company” category…

Visit the Kawasaki Booth B17074 at FABTECH 2019 to see examples of offline programming and seam tracking, LIVE arc welding, robotic grinding, deburring, machine load/unload and MORE…

It’s important to choose the type of industrial robot that best suits your application. Download our Industrial Robot Guide to learn the benefits of each type, and how industrial robots have evolved over time… (PDF:20.2M )

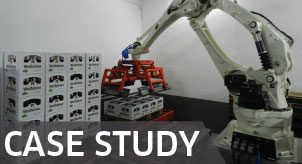

Learn why a brewery rooted in 157 years of tradition made the decision to automate, and why their experience using a Kawasaki CP500L palletizer has inspired them to automate additional processes in the future… (PDF:215.1K )

The CP series is designed specifically to meet the demands of flexible palletizing, offering a wide range of payloads, high speed capabilities and regenerative power braking. Learn more in this month’s edition of KTV…