Automation Innovation that Pays for Itself

As one of the first industries to wholeheartedly adopt automation, the automotive manufacturing sector has long benefited from successive improvements in robotics technology. Over time, robots used in automotive manufacturing applications have become smaller, more precise and more multi-functional than their predecessors, making them indispensable in the production process. Today, rising costs associated with next-generation automotive materials, skilled labor and safety systems coexist alongside a need for manufacturing equipment to accommodate product changeovers. This makes a clear, compelling case for cost-effective flexible automation solutions at every step of the automotive manufacturing process – from parts, press and paint shops to assembly and inspection.

Flexible Automation for all Automotive Manufacturing Applications

From tending stamping machines and manning body and frame assembly stations to applying precise coats of paint and sealing sensitive finished components, automakers and parts manufacturers count on nimble, adaptable automotive robots to enhance productivity and quality. Kawasaki robots can effectively execute dashboard assembly, engine, transmission and crankshaft handling and waterjet cutting for carpeting and other soft materials. Meanwhile, key improvements in sensing and calibration technology make our robots ideal for welding – including arc, spot and friction spot joining – car and truck bodies as well as palletizing and crating parts and materials for delivery.

For both automotive OEMs and component suppliers, Kawasaki robots deliver the sought after optimization of functionality, flexibility and investment efficiency to accelerate production timetables and improve quality.

Applications

Assembly

The process of combining multiple parts to make components or products, assembly is performed in various manufacturing sectors, including machinery, electronics, and electrical sectors.

Assembly covers various tasks, including assembly of small precision parts and large and heavy workpieces.

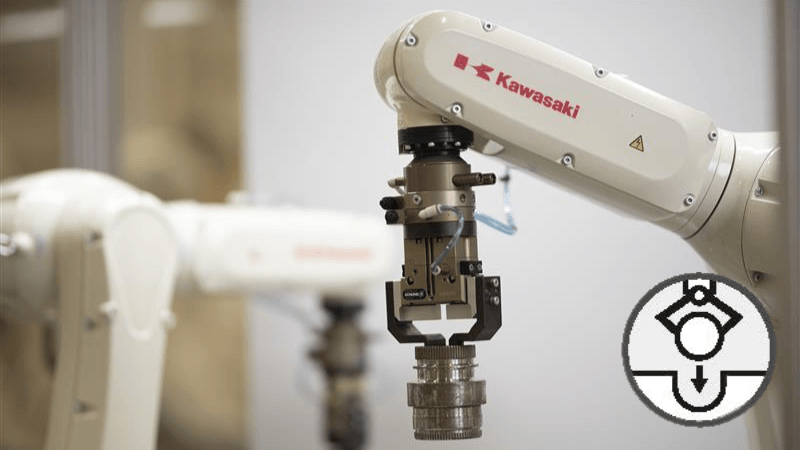

Material Handling

The process of moving materials, parts, and products from one place to another, material handling is performed in almost all industries, not just in the manufacturing industry.

For material handling, industrial robots are most commonly used for various purposes, including high-speed transport of small parts and handling of heavy objects that humans cannot carry.

Painting

Painting is the process of applying paint on product surfaces, forming a coating film or finish.

Because most paint materials are highly volatile, explosion-proof robots and painting equipment are used for this process.

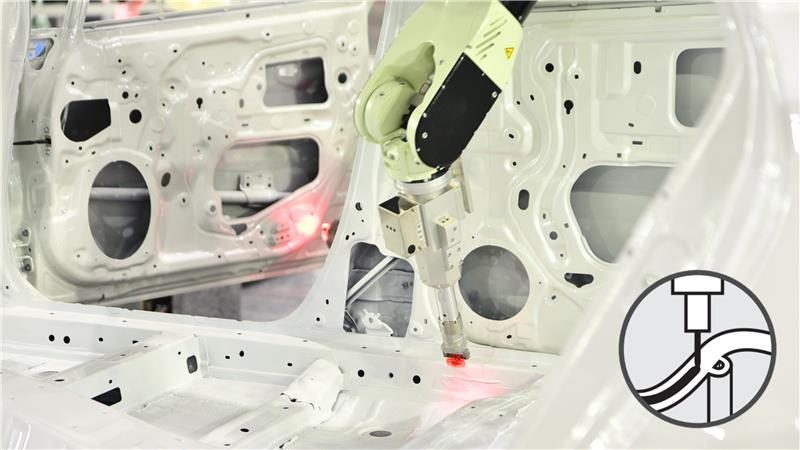

Sealing / Dispensing

Sealing is the process of applying sealant or adhesive to enhance airtightness and fill the space between materials.

Sealing is performed for many products, such as passenger vehicles and home appliances.

Material Removal

Grinding and deburring is the process of removing protruding burrs from the surfaces of casting and forged products as well as post-welding surfaces.

Involving scrapping off burrs with a grinder, this process can be dirty, dangerous, and demanding where robots can play important roles.

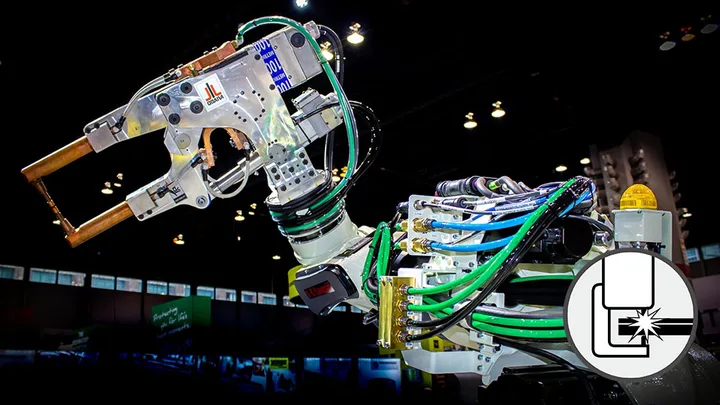

Arc Welding

The welding method that uses arc discharge to join metal materials, arch welding is widely performed in the machinery, metal, and automotive industries. Robots and arc welders are used to join the materials while melting them.

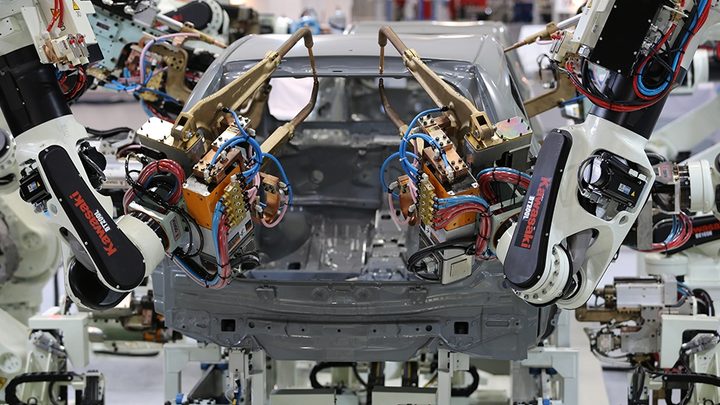

Spot Welding

Spot welding, also known as electric resistance welding, is the process of welding two base materials by applying electric current with an electrode rod and melting them with the resistance heat. Spot welding is so commonly used to weld steel plates of automobile bodies that a large number of robots are used in the automotive industry.