2/19 Pages

Kawasaki Robotics’ dedication to continuous improvement is evident in their technically advanced general purpose robot line: the R series. With a history dating…

Kawasaki Robotics will be at Booth N-5946 at PACK EXPO International, which will be in Chicago from Oct. 23 to 26, 2022. Learn what they will be showcasing during the event…

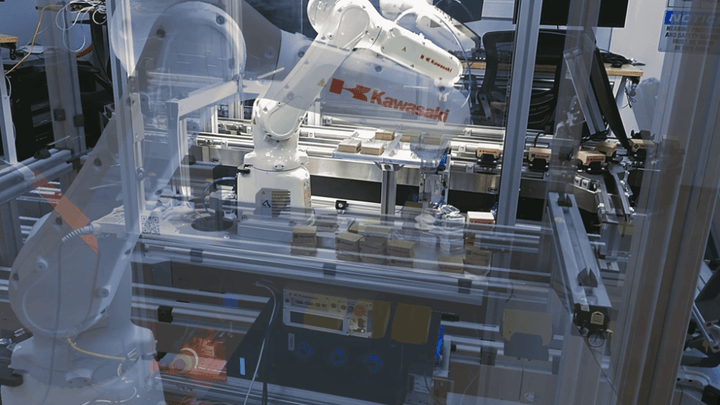

See it at PACK EXPO International, Booth N-5946! Kawasaki Robotics will showcase low-cost and entry level products to high-end automation solutions for every type of end-of-line application. Learn what else you will see in the Kawasaki booth at PACK EXPO 2022….

Kawasaki Robotics and IRIS Factory Automation have teamed up to create the RPZ-MAX – a small-footprint, point-of-use palletizer with two pallet stations. Built to handle heavier payloads (30-80 kg) and faster rates while still maintaining a simple-to-use interface, RPZ-MAX cells provide high output with the flexibility needed by today’s manufacturers to achieve high-mix, low-volume production. Learn more…

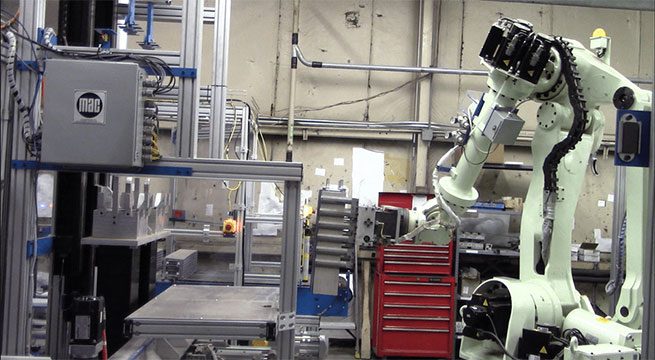

When Naperville, USA-based industrial lead-acid battery manufacturer Battery Builders (BBI) decided to upgrade its facility, it seemed like an obvious choice to include its six-station COS (Cast-On-Strap) machine in those upgrades. It worked with robotic integrator MAC Engineering to install a Kawasaki large payload robot with a robotic cell consisting of six process stations. Learn more in this featured case study on MachineBuilding.net…

Kawasaki’s KRNX focuses in on enabling users to complete complex AI applications with its real time control capabilities. Learn more in this featured article from Modern Machine Shop…

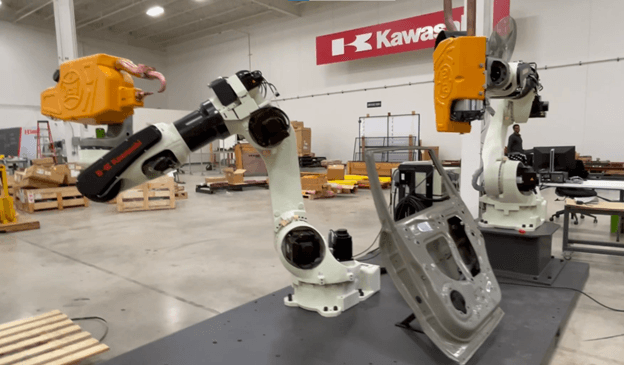

To help tackle the challenges faced by today’s manufacturers, Kawasaki Robotics offers a wide range of robotic solutions which will be on display at the largest North American automation show, AUTOMATE, in Detroit, MI, June 6-9, 2022…

BOSTON and DETROIT – June 6, 2022 – Realtime Robotics, the leader in autonomous motion planning for industrial robots, today announced that Kawasaki Robotics Inc., a leading supplier of industrial robots and automation systems, has teamed with the company to automate the programming, deployment and control of its industrial robots.

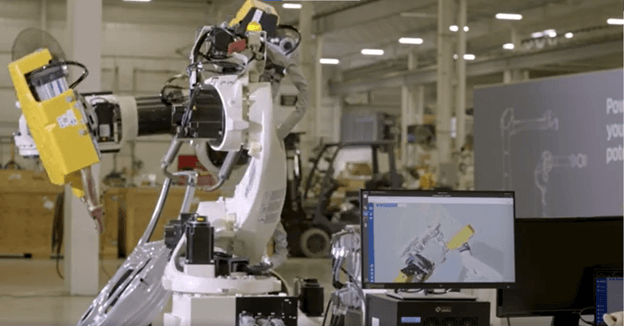

On May 24, Kawasaki Heavy Industries, Ltd. unveiled the “Kawasaki DX” project at Microsoft’s annual Build conference. Kawasaki’s DX initiative utilizes Microsoft’s industrial metaverse technology to implement a real time, virtual approach to robot care and maintenance.

Kawasaki Robotics is pleased to announce they are one of the recipients of Applied Materials’ 2022 Supplier Excellence Awards for Best in Class Performance. The awards reflect outstanding technical and operational performance in several areas including quality, service, lead time, delivery, cost and responsiveness.