- IndustriesElectronics, Machinery & Metal Fabrication

- ApplicationsMaterial Handling

- Robot SeriesR series

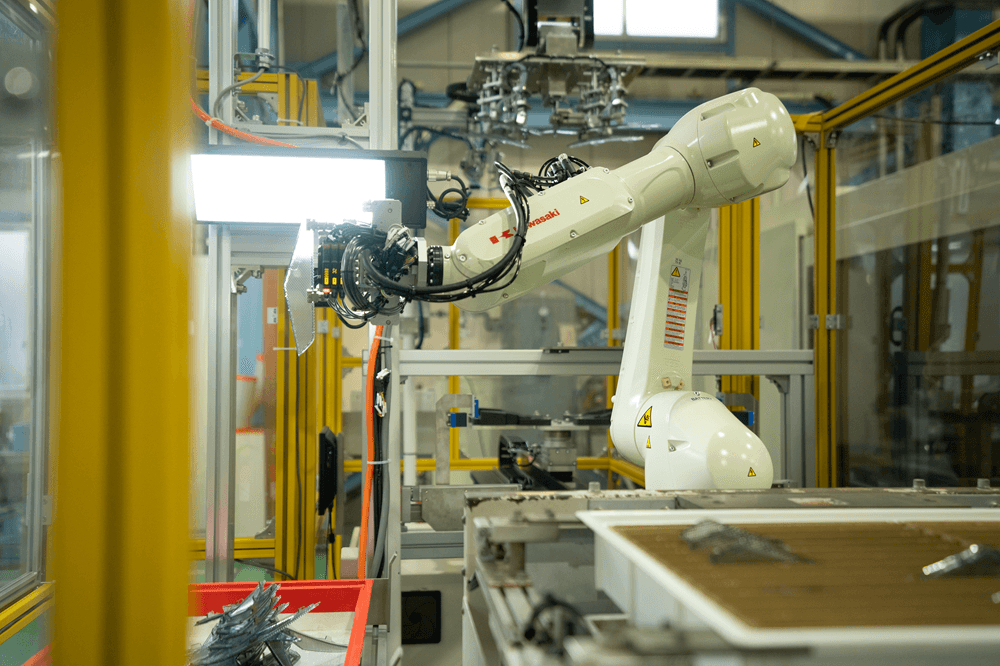

Yamaguchi Manufacturing introduces a ‘visual inspection robot system’ provided by Kawasaki Heavy Industries.

Founded in 1950, Yamaguchi Seisakusho has built a legacy of precision manufacturing and innovation, preparing to celebrate its 75th anniversary in 2025. From introducing Japan’s first microformer to expanding globally in 1989, the company has consistently embraced technological progress. Today, Yamaguchi focuses on resin solutions, meeting growing demand in the automotive industry with a steadfast commitment to quality under its “no back-end processes” policy.

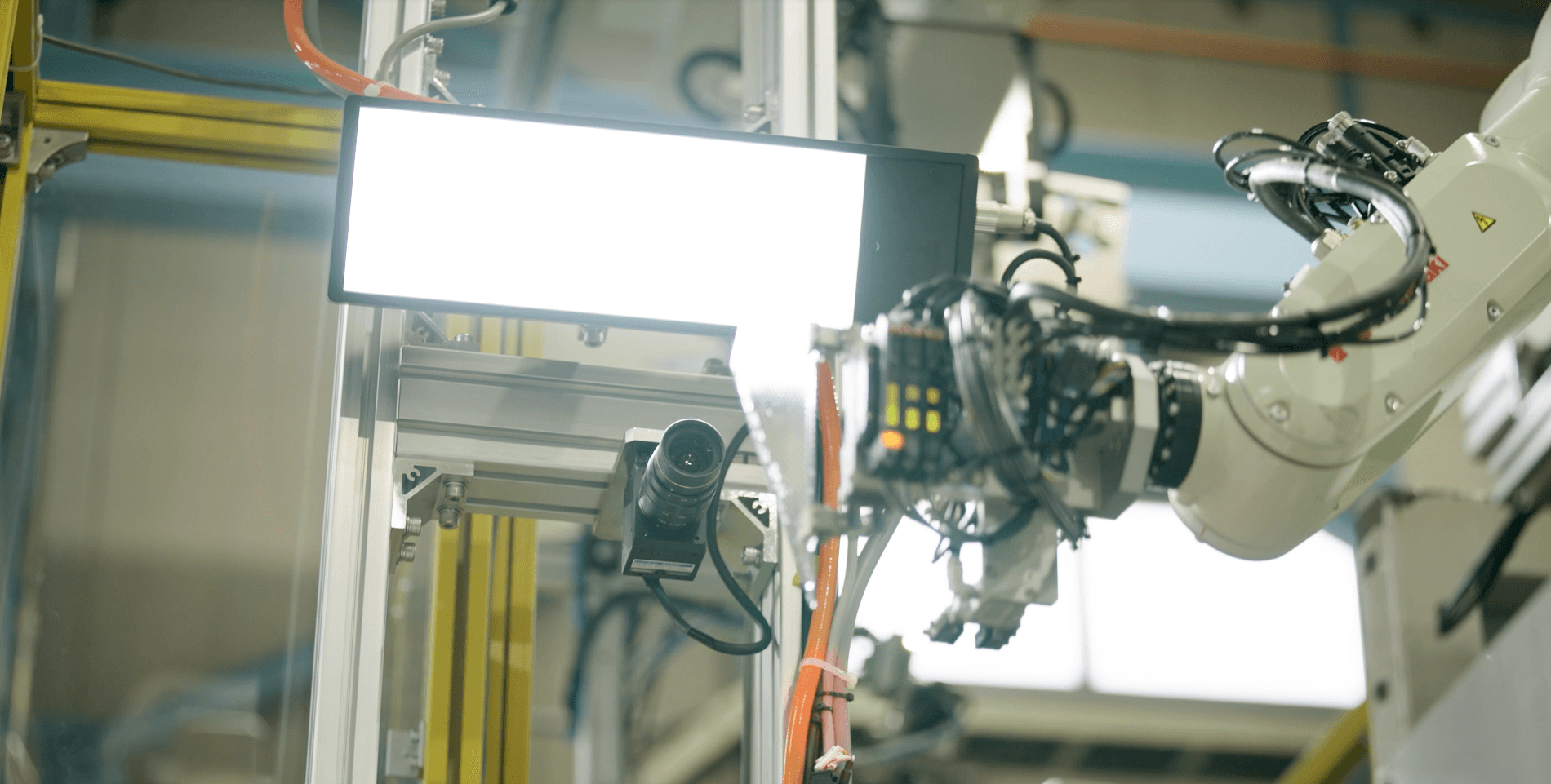

As part of this commitment, Yamaguchi implemented Kawasaki Heavy Industries’ Visual Inspection Robot System in 2024—a milestone marking the first use of an arm-type robot for appearance inspection. We spoke with the team to learn what drove this decision and the impact it’s making on their operations.

Increased sophistication of inspection and human resources required for the launch of new products

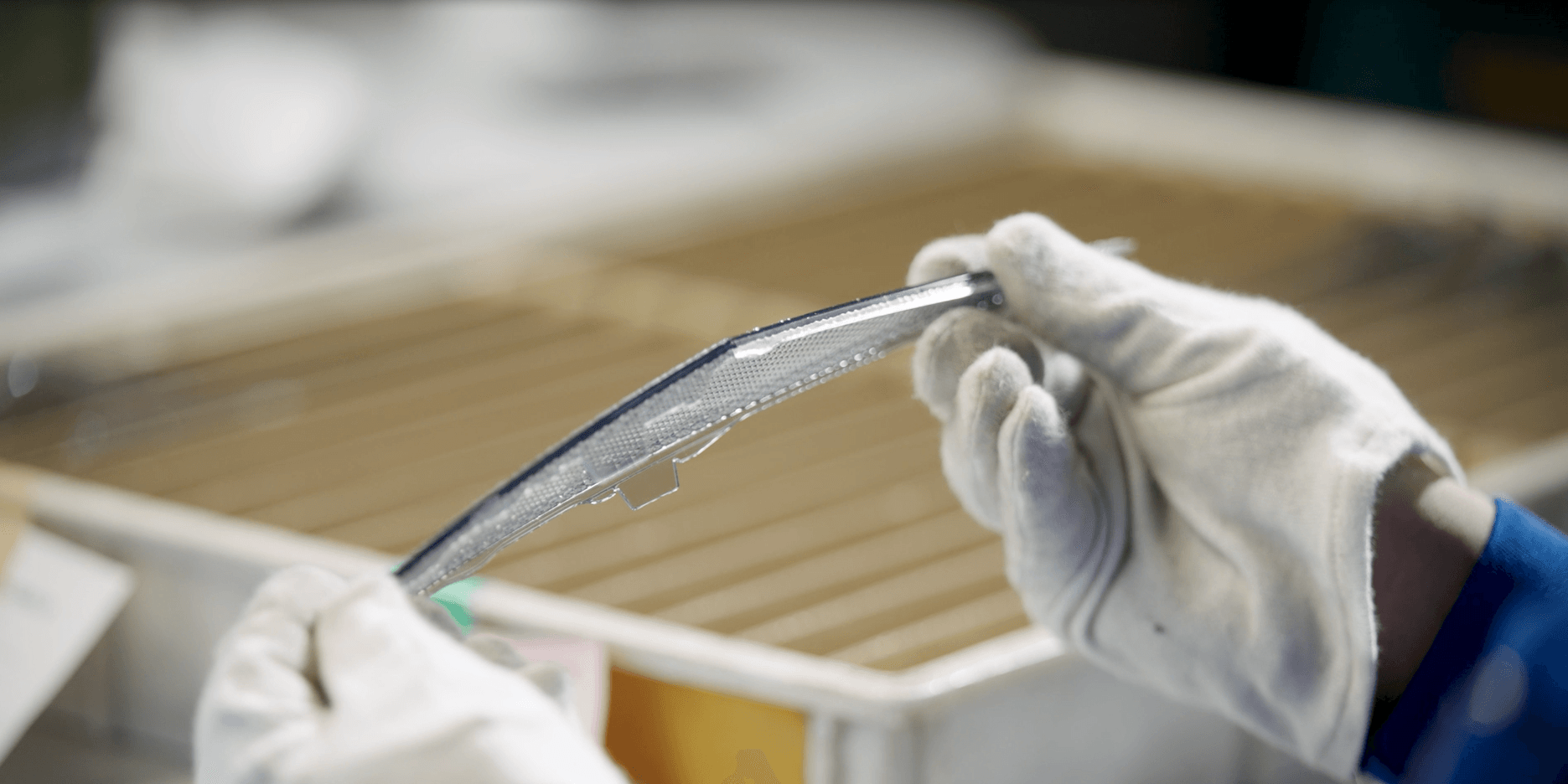

When Yamaguchi Manufacturing launched a new inner lens product for vehicle exteriors, the team faced a unique challenge: ensuring flawless appearance quality. Unlike conventional components hidden inside the vehicle, this part demanded zero tolerance for foreign objects, scratches, or deformation.

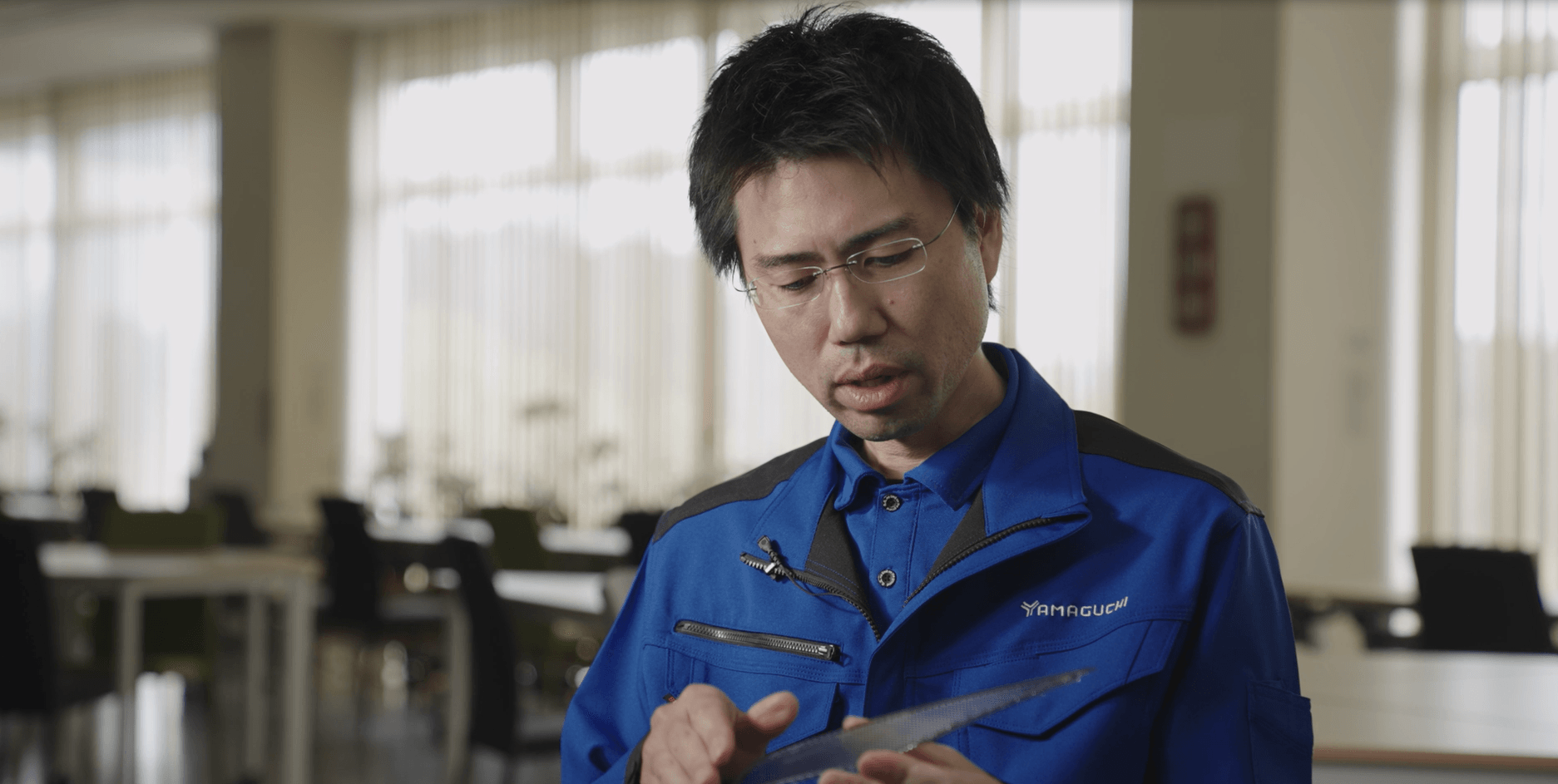

Manual inspection had been the standard, but the complex curved geometry of the lens—and the need for highly skilled inspectors—made consistency difficult. “Inspectors were manually checking every surface, edge, and character, a process that took more than 15 seconds per part,” explains Watanabe from Technical Department 2. Recruiting and training qualified personnel added further strain, making it clear that a stable inspection system was needed.

To overcome these challenges, Yamaguchi turned to automation with Kawasaki’s Visual Inspection Robot System, introducing an arm-type robot for the first time to streamline and enhance quality control.

Previous system and challenges

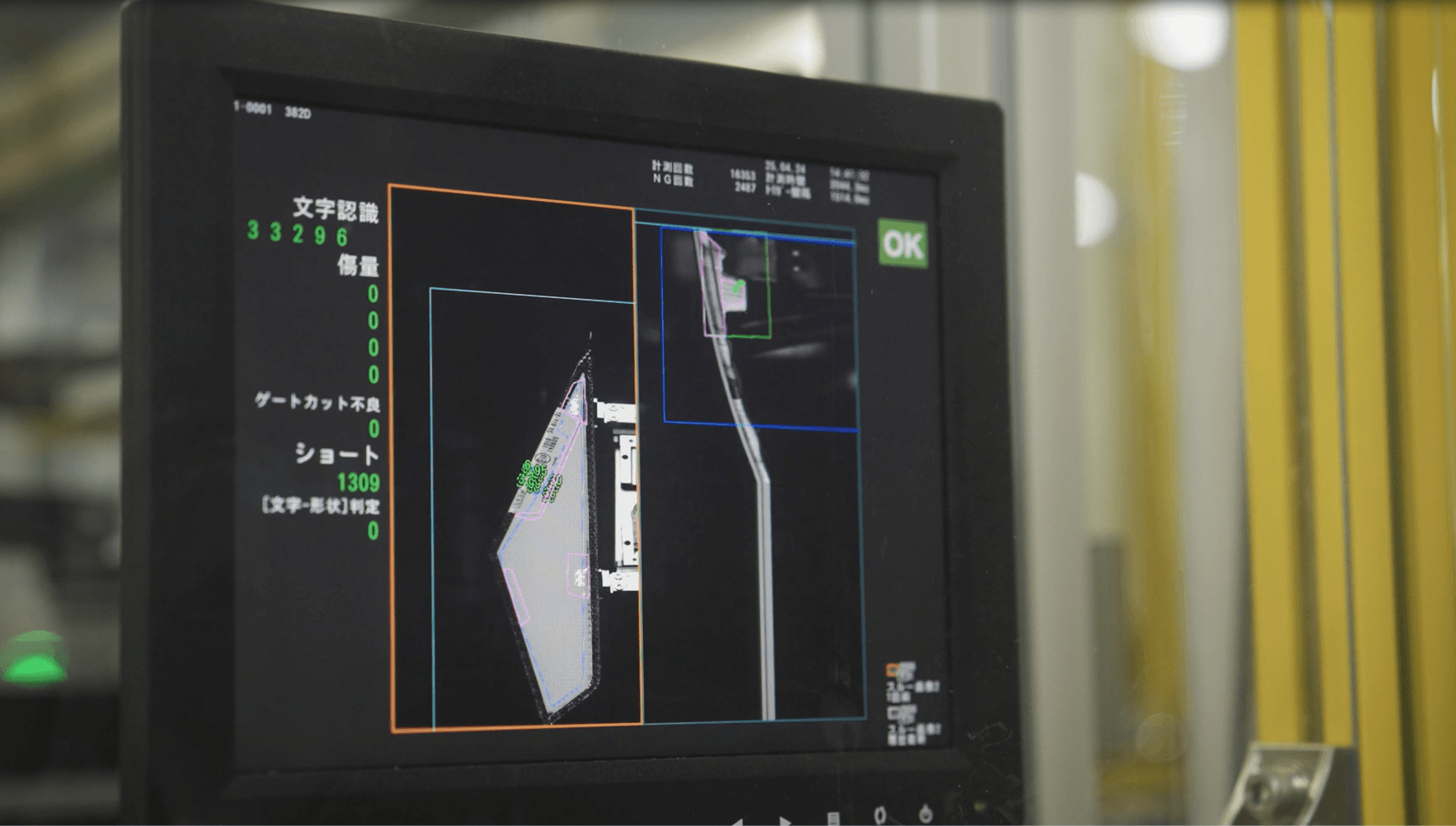

Before the introduction of the system, the manufacturing and technical departments were responsible for production, while the quality assurance department was responsible for visual inspections. However, the system did not allow for an immediate response, with feedback of fault information not being provided until the following day. The inspection process, which relies on the human eye, has also faced problems with inconsistencies in judgement and cycle time limitations.

In particular, the new product required four units to be inspected at one time within the cycle time, and if all inspection items were carried out manually, the time would not be sufficient. Mr Watanabe recalls, “The challenge was to draw a line between how much should be covered by automatic inspection and how much should be controlled by manufacturing technology, and to adjust the inspection standards.

Decisive factors in the introduction of the visual inspection robot system

One of the main reasons for introducing the robot system was the ‘high versatility of the handling’. The decision to use the robot was based on the expectation that the system would be able to handle a wide variety of products, as visual inspections could be continued simply by changing the settings, even if the product variety was changed in the future.

For the visual inspection robot system, we consulted a trading company after gathering information on the web and were introduced to Kawasaki Heavy Industries’ system. ‘For the inspection camera, we compared several companies, but for the robot, we did not make any comparisons because we decided that only a Kawasaki robot with a ‘high-speed pulse output function’ would meet our requirements, considering its compatibility with the line-scan camera.

‘In selecting the product, the emphasis was on being able to complete the inspection within the moulding cycle while meeting the inspection criteria based on the customer’s drawings. The robot’s ability to perform complex movements at high speed was a deciding factor in our decision to introduce the system,” says Mr Nonaka, Quality Assurance Section 2, who was involved in the introduction of the robot system.

Response and structure at the time of introduction

Although there were no robot specialists within Yamaguchi Manufacturing when the system was introduced, it was handled mainly by Factory Automation (FA) personnel in coordination with the system integrator. As they are still not used to handling the robots, even now they do not touch them unnecessarily on site, and the FA staff are in charge of dealing with any problems.

In setting inspection standards, adjustments were made in the Kawasaki Heavy Industries laboratory and on site, and in order to process within the cycle time, settings were focused on important items rather than covering all items.

Actual effects and feedback

Six months have passed since the introduction of the system and it is currently operated by a two-person team. KPIs include records of detection accuracy and the number of defects.

The introduction of the system has reduced labour costs for three inspectors. Feedback on defects, which previously took one to two days, can now be provided immediately, and defects can be detected immediately after moulding, enabling the line to be stopped and improvements to be made, which has also led to a reduction in production losses. The number of inspection man-hours has been reduced by 297 hours per month.

The high-speed pulse output function enables the visual inspection of curved products at high speed, a function that has been most appreciated since its introduction. The system also has the accuracy to detect dust and minute particles of debris that adhere due to static electricity, which was an unexpected result.

Future prospects and requests

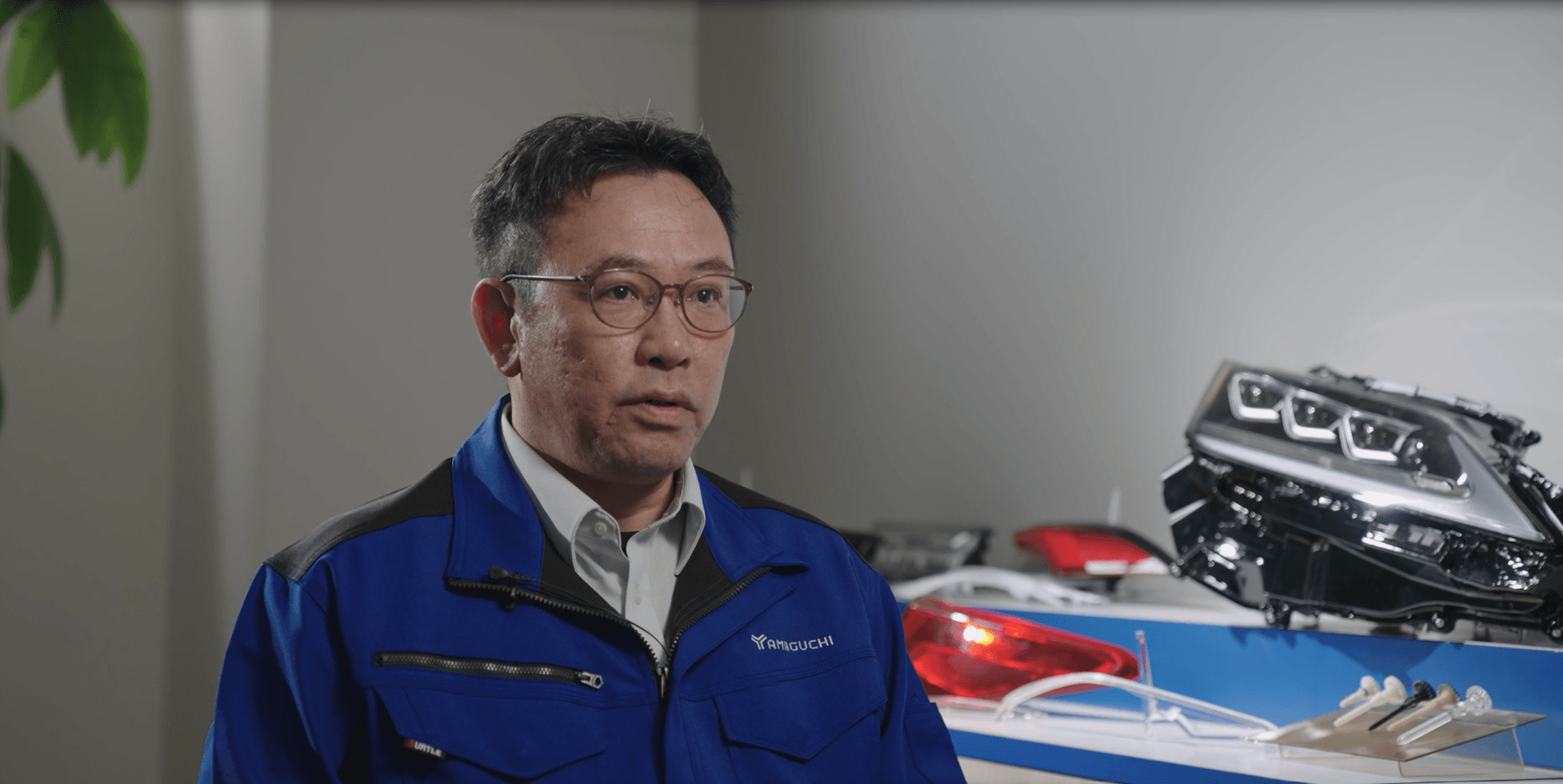

Mr Yamaguchi, Executive Vice President, says: “In the future, we would like to promote the introduction of automatic inspection, including at overseas sites.” In particular, we would like to build a system that can handle a wide variety of products in small lots with a single unit, and eventually configure the system to enable alternate inspections for multiple products.

As for requests to Kawasaki Heavy Industries, he expects the company to develop robots that can move more flexibly and general-purpose systems that can be installed simply, as the shapes of parts become even more complex in the future. The company also intends to develop an educational system so that on-site workers can participate in Kawasaki Heavy Industries’ robot school.

Robots play an important role in ‘fault detection’.

Yamaguchi Manufacturing regards this system as playing an important role in ‘fault detection in the inspection process’. If they were to introduce the system to other companies, they would recommend it because of the ‘high specifications, reliability and quality of service of Kawasaki robots’.

In the future, robot visual inspections will continue to be an important option for the company, as it is difficult to respond to products with strict quality requirements and to secure stable human resources.