1/3 Pages

At Kawasaki Robotics, our global purpose is clear: unlocking human ingenuity to create robotics that enrich the future. For decades, that purpose has guided us to design industrial robots that work with people—not just around them. One of the most ambitious expressions of that vision is the humanoid robot: a machine that walks on two legs, works with two arms, and has the versatility to perform tasks traditionally done by humans. This blog traces the evolution of Kawasaki’s humanoid robot development, from its earliest prototypes to the latest advancements. 👉 Important note for our North American readers: All humanoid robot development discussed here is led by Kawasaki Heavy Industries in […]

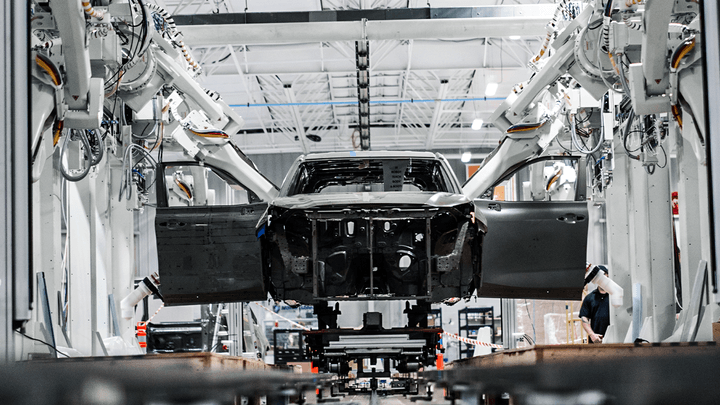

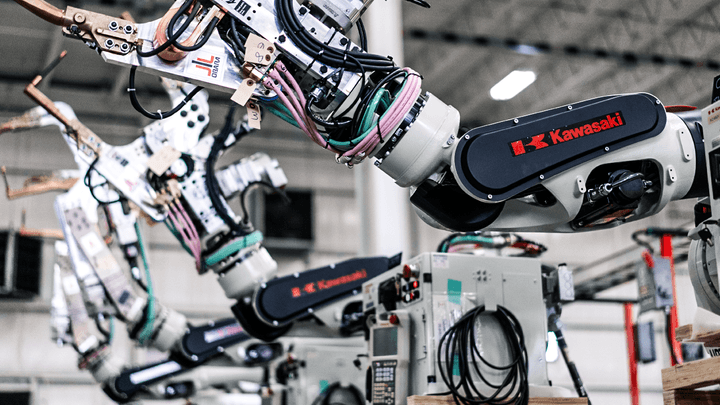

When considering an industrial robot purchase, where it’s built is only one part of the story — how it’s built, tested, and supported is what truly impacts your production line. Kawasaki Robotics is proud to operate as part of Kawasaki Heavy Industries (KHI) — a global engineering and technology leader with over +120 years of manufacturing experience in industries ranging from aerospace and rolling stock to shipbuilding and precision machinery. Kawasaki Robotics has over 50 years of robotics innovation with hundreds of thousands of robots installed worldwide. Global Manufacturing, Local Support Yes, Kawasaki robots are manufactured at our state-of-the-art facilities in Japan — the same factories that have produced some […]

Kaggle, a global AI data analysis competition platform, hosted the National Football League (“NFL”) and Amazon.com, Inc. […].

Industrial automation systems come with a price but the effects of choosing not to automate can be just as impactful as the up front purchase price.

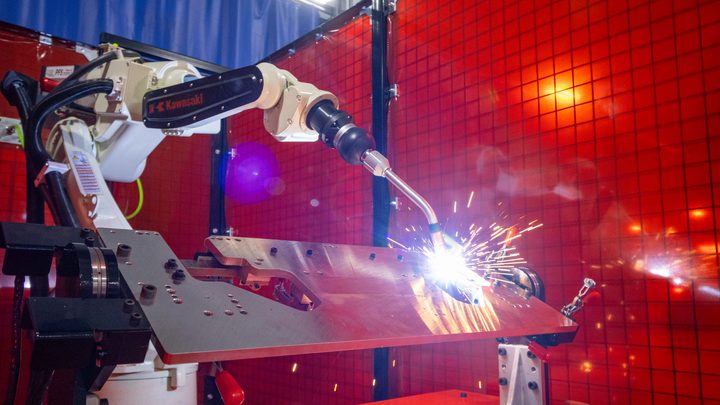

Robot integration in many welding applications makes sense, given that welding is not conducive to pleasant working conditions for humans. Not only is it a hot and dirty process, but it also emits unhealthy chemicals such as…

By following these five simple suggestions from Kawasaki Robotics, minimizing robotic automation downtime is attainable for any size facility.

When it’s robotic maintenance time, it’s a wise move to partner with an expert robot provider. Talk to Kawasaki Robotics for efficient, productive preventive maintenance.

Industrial robots wear over time, resulting in lower performance. This is why upgrades and retrofits are so effective, and it’s why Kawasaki Robotics offers them.

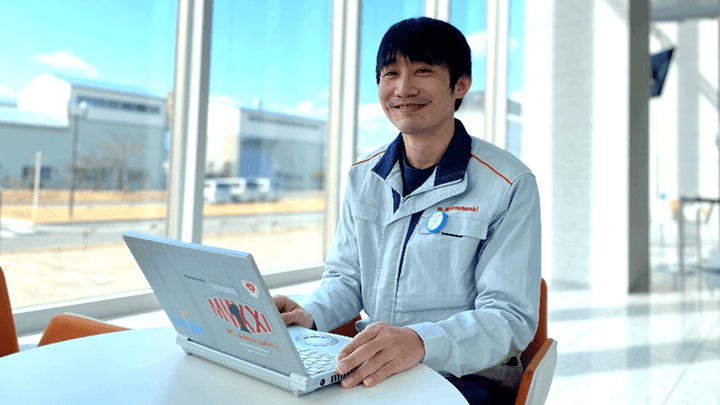

These days, Na Xiong is an expert Process Engineer at Kawasaki Robotics. But if we rewind to his childhood, we would see a future engineer..

These days, Na Xiong is an expert Process Engineer at Kawasaki Robotics. But if we rewind to his childhood, we would see a future engineer..