CRG Automation, which sets up shop in Louisville, Kentucky, likes to say that their favorite thing is to solve problems that have most other people scratching their heads. We can confirm. Based on their company history and our time working with them as a Kawasaki Robotics preferred partner, they’re true to their word.

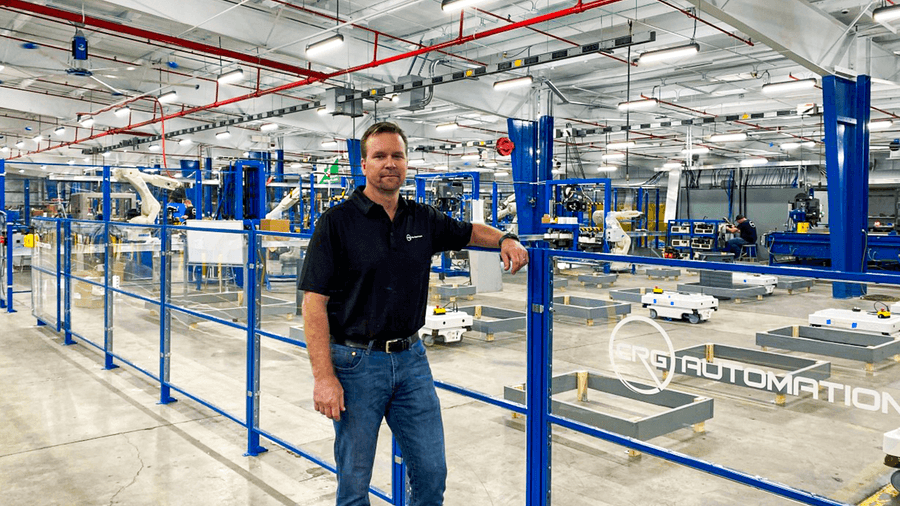

It’s thanks in large part to a group of highly motivated and intelligent employees that love to show up every day to complete brilliant commercial automation projects together. We caught up with James DeSmet, CEO, and Rebekah Fischer, Director of Business Development, to hear all about the past, present and future of CRG—and what they’ll show off at the Kawasaki Robotics booth C5475 at MODEX 2024.

The CRG Catalyst

For a couple decades, CRG Automation plugged along and did its thing. But then 2019 came calling, and so did the U.S. government. “It was an emergency request, and it allowed us to flex the muscles we’d developed over the years,” said DeSmet. “It became a 4-year journey across multiple products and plants, and we got them to the finish line ahead of schedule despite starting well behind.”

CRG’s contacts on the government job told them what was done in 12 months would have taken five to seven years without them. Accolades from elsewhere poured in as well, with recognition from Time and Fast Company for inventiveness and innovation.

As recognition and growth entered the CRG story, the company has remained a place that says what they’ll do and does what they say. They’re now recognized as one of the top places to work in Kentucky.

The CRG Difference

When asked what makes his company stand out, DeSmet had his answer ready: the people. “We’ve quadrupled headcount since 2019, and because of the urgency of our government project, we needed people who could hit the ground running.”

“That influx changed our company dynamic. We thrive on open collaboration with each other and with our partners. We have seasoned engineers with decades of experience, new engineers fresh out of school, combined with shop technicians that bring ingenuity and hands-on experience to every design.”

With the government work complete, CRG is focused on one key segment: automated packaging. “We’re a system integrator as well as a custom equipment designer and builder,” said DeSmet. “When we approach a project with a customer, it starts with finding out what success looks like for them. After that, we spot the opportunities and develop a solution for the problem they’re trying to solve.”

Who’s Coming To MODEX 2024

At Kawasaki Robotics, a key differentiator is our ecosystem of technology partners thanks to our commitment to staying open, and it is crucial to our promise to design and support difference-making robots. We are thrilled to have CRG accompanying us to MODEX, March 2024 in Atlanta, with a powerhouse technology partner who is paving the way for future proofed automation.

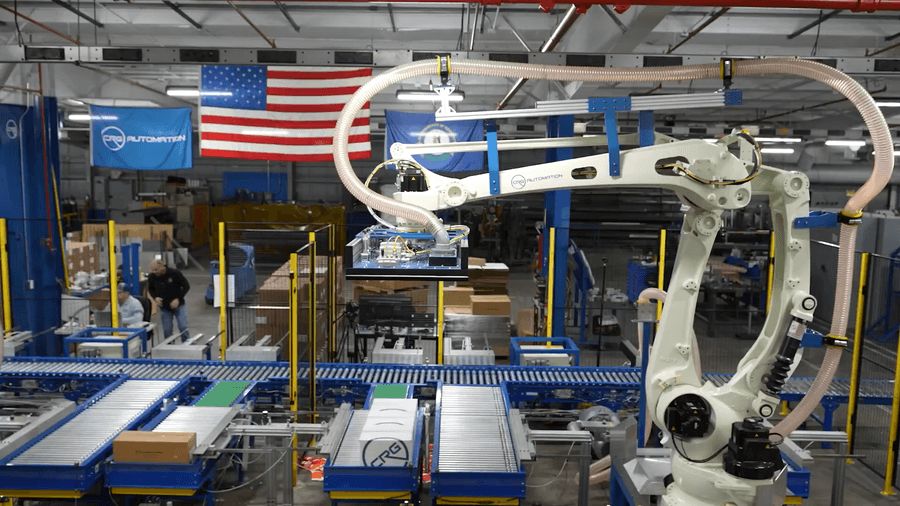

“We are system integrators, which means we bring everything together to build the system – robotics, software, vision, conveyance – everything needed to create a one-stop solution for our customers,” DeSmet said.

We’ve partnered with Olis Robotics, and will feature their proven, edge-hosted software platform. Paired with vision, the software allows users to remotely access their robotic cells to recover any common faults. If you have a robotic tech responsible for 20 robots, they can’t be everywhere at once. But with this software, they’re alerted, they dial in remotely and address the problem.”

The Holy Grail of Warehouse Automation, On Display at MODEX 2024

At MODEX, a Kawasaki BX130X robot will be palletizing and depalletizing mixed SKUs. In front of the BX platform, visitors will see a RS007L robot, which is part of CRG’s automated corner board application system (CBAS). The robot will simulate placing corner boards on the completed pallet, a process that integrates with stretch wrappers and ensures pallet stability during shipping. That robot application will also be monitored by Olis Connects remote monitoring and error recovery software. We will demonstrate what happens if the robot faults. With Olis, an individual can simply recover the robot. And that’s without having to physically be there. Even better.

Long story short, if you and your company have an interest in warehouse automation, you need to get to the Kawasaki Robotics booth at MODEX 2024.

*In case you were wondering, yes, CBAS did indeed get its name from the film Dumb & Dumber.