By Greg Tormanen, Automotive Body in White Engineering Manager, Kawasaki Robotics

I’ve been playing in the automotive field since 1993. And it’s been fun watching the different trends come and go.

I’ve been observing these trends primarily from the control side, with my first involvement coming at the time where there was a simplistic 110 volt control structure and very slow, almost clunky communication protocols. Each year since, with each major project, it seems we’ve adopted new technology that gradually improves the situation.

When I started out in controls, our primary task was to physically visit automotive plants. Our team would review operations and target difficult applications and tasks for humans to execute as potential candidates for automation. Examples of these types of actions include handling large parts or using large pinch guns to weld materials; anywhere where employees could face injury on the job. We’d review each task to see what was physically straining – or dangerous – and look at options for improving these processes through technology.

Once we targeted a specific task or role for automation, we used the technology available at the time – to the best of our ability – to make it happen. Over time, specific tasks became standardized as either ones for humans, or ones for machines. We didn’t realize it at the time, but this was a major transition in the field of industrial manufacturing. There became an expectation that specific tasks would be automated and handled by machines.

Evolution of Welding

Welding task execution is a prime example of how technology has evolved. Welding has always been a critical element of an automotive assembly line. The original welding guns – used for many years – were large in size and needed to be manually positioned correctly before each weld.

In fact, we used to call the old-fashioned assembly plants “Sherwood Forest.” If you can visualize it, there were very large structures with pneumatic weld guns hanging off of the overhead structure with these counterbalance cylinders. A human would hold these huge weld guns, moving each into position to perform the welds. It resembled a forest, with hundreds of guns hanging overhead and hundreds of humans positioning these guns, performing the tasks. It was a very interesting environment.

The use of this equipment resulted in quality issues and inconsistent outcomes on a regular basis. However, as technology improved we moved from pneumatic welding guns to servo controlled, which quickly improved the process. This reduced the size of the equipment, improved performance consistency, and increased output.

Evolution of Work

Even in the past, line workers understood that when our team arrived to review the assembly process, we were actually there to try and automate parts of it. It’s always difficult to automate a job that someone currently does. Often, our first thought is the human cost of automation, which could mean changing someone’s job and life. At the same time, these extremely difficult jobs challenged both the human body and spirit. Repetition and hard, physical labor can wear a person down.

When you step back to take a look at the big picture, however, you may notice something. Throughout history as marches of progress and industrial revolutions occur, work has been redefined along the way. Years ago, the invention of the automobile scared buggy manufacturers and horse stables because of what it could mean for jobs. There will always be improvements that make work easier, faster and more automated. But it’s a good reminder to consider people whose jobs will be automated.

Automation in Current Workplaces

I believe there are big changes on the way in the next decade. Current factory footprints are much smaller than they were decades ago. At the same time, there is an insane amount of activity happening in each assembly plant at any one time. New technologies that have evolved over the past 5-10 years have been game changers, allowing for deeper automation – and more of it.

I think that we’re really on the cusp of a big change now with the move towards electric vehicles. That’s going to bring a whole different culture to the automotive manufacturing space. (And a whole different environment to look forward to.) We’re already seeing new improvements in the controls used to power the equipment used. Through the years, we’ve seen communications protocols change from remote IO, to device net, to Ethernet. Electric vehicle manufacturing and adoption can create new opportunities for factory automation- beyond what’s done today.

The Power of Software

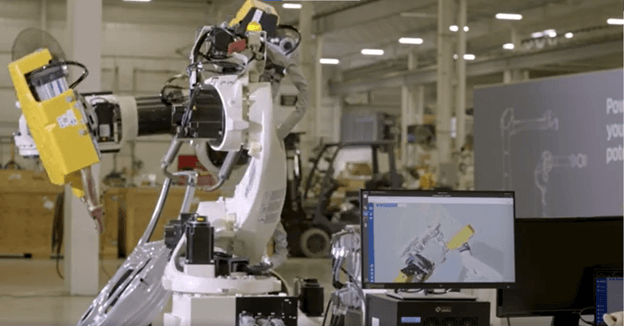

Software is another great example of technology that can drastically change automotive manufacturing. Realtime Robotics’ RapidPlan software, for example, is changing the equation from another approach. Instead of making it less physically taxing to move equipment, their software makes programming easier and less repetitive.

In the 1990s, robot programming and setup was a very manual process. There was no “offline programming,” if you will. Human operators did everything manually: choosing robot positions and speed settings, planning for accuracy, and mapping out robot paths for collision avoidance.

Watching the RapidPlan software guide the robots on our shop floor was a thing of beauty. The robot motion was phenomenal; robots were interacting with each other and not crashing.

The Only True Constant in Automation

For years, it has taken operators a great deal of skill and practice to make robot motion and planning efficient and effective. Realtime’s technology is taking away the need for that skill and decreasing the amount of time it takes to program. It’s amazing and almost magical for me to watch that process take place. The interactions that the robots have with each other, you’re not going to get that with human programming; it really takes the software to bring it to that next level.

In our business, automotive customers typically ask their integrators to build a specific line. They describe the product they want to manufacture, in what quantity, and with what throughput. The integrator is then responsible for designing a system that makes those goals a reality.

Integrators can keep costs under control by using less hardware in their design, which means they’re more likely to win the bid. Advanced technologies like this make it possible to better control the hardware – and to use less of it, while optimizing what’s in use. This makes it easier to reach the desired line structure and throughput in the cost parameters given.

It dawned on me then that we were standing at the cusp of another major moment in the march of progress. Where greater things would be possible in the years to come because of the automation I was witnessing. I was expecting the robots to be crashing and burning and the motion to be poor – but instead the robots were acting like ballerinas, and it was a thing to behold.

I think that’s really where we’re going to be seeing the next big changes in automotive manufacturing and robotics. In the software tools that can make amazing things happen. We’re always making Incremental improvements – the only true constant in automation is change.

Want to know more?

If you have any questions or would like to continue this conversation, feel free to shoot me an email.

Please note the views and opinions expressed in this blog belong exclusively to the content creator, not to Kawasaki Robotics as an organization. The content of this blog post or any user content it generates in no way convey the thoughts, sentiments or intents of the organization.