At Kawasaki Robotics, our global purpose is clear: unlocking human ingenuity to create robotics that enrich the future.

For decades, that purpose has guided us to design industrial robots that work with people—not just around them.

One of the most ambitious expressions of that vision is the humanoid robot: a machine that walks on two legs, works with two arms, and has the versatility to perform tasks traditionally done by humans.

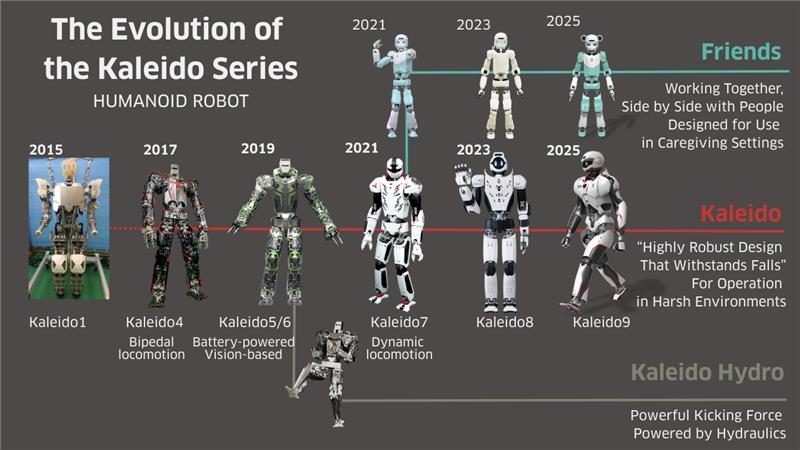

This blog traces the evolution of Kawasaki’s humanoid robot development, from its earliest prototypes to the latest advancements.

👉 Important note for our North American readers: All humanoid robot development discussed here is led by Kawasaki Heavy Industries in Tokyo, Japan. Kawasaki Robotics USA is not developing humanoid robots in North America.

Why Kawasaki Pursues Humanoid Robots

Kawasaki built Japan’s first industrial robot, and for more than 50 years we’ve been a leader in factory automation. That experience laid the foundation for expanding into human-centric robotics—systems designed to operate outside traditional industrial robot cells. Examples include:

- duAro, our dual-arm collaborative robot designed to work safely alongside people

- Successor, a remote-cooperation system that simplifies robot teaching and operation

Humanoid robots represent the ultimate extension of these efforts. Because they walk on two legs and work with two arms, humanoids offer unmatched flexibility and the potential to perform work in environments built for humans.

2015: The First Humanoid Prototype

Kawasaki began humanoid robot development around 2015. For a company rooted in industrial robotics, bipedal walking introduced an entirely new level of complexity.

Learning from the Human Body—Without Copying It

Early development focused on how to mechanically reproduce the human form using motors and joint mechanisms. However, the deeper the team studied human anatomy, the clearer it became: the human body is extraordinarily complex and flexible.

That realization led to a key shift in philosophy.

Rather than directly copying human motion, the team identified essential functional principles and recreated them using mechanical structures and motors. This breakthrough made stable bipedal walking possible.

Weight and Structural Challenges

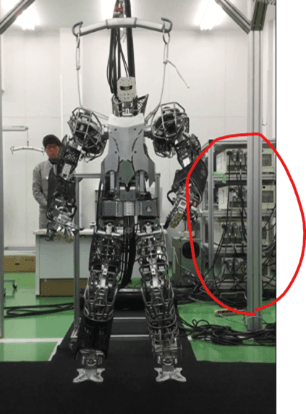

Industrial robots are typically heavier than their payloads—a 100 kg payload robot may weigh over 600 kg. Humanoid robots face the opposite challenge: they must lift loads greater than their own body weight, making extreme weight reduction critical. Early prototypes revealed several issues:

Insufficient leg rigidity, particularly in the knee joints, caused instability during walking.

Up through the third prototype, the robot used Kawasaki’s E-controller, originally designed for industrial robots. It was large, slow for humanoid control cycles, and required four separate units—taking up excessive space.

Falling posed a major risk. To address this, the team conducted repeated controlled fall tests, developing break-fall motions to protect the robot from damage.

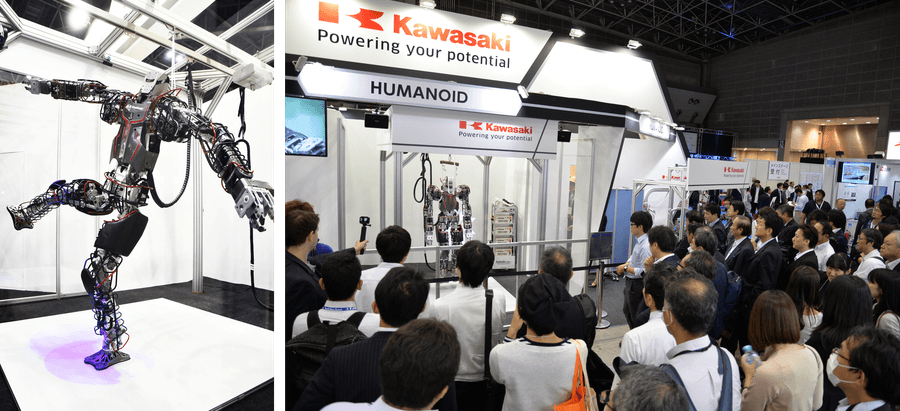

2017: First Public Debut at iREX

Kawasaki unveiled its humanoid robot Kaleido at the International Robot Exhibition (iREX 2017) in Tokyo.

| Demonstrated capabilities included: | Standing up from the floor Pull-up motions using both arms |

| Kaleido specifications at the time: | Height: 175 cm Weight: 85 kg Power: External tethered supply |

In the days leading up to the show, the robot continued to experience issues—right up until the evening before opening day. The team seriously considered scaling back the demonstration.

A final round of adjustments paid off, and Kaleido successfully completed a full demonstration on opening day.

Even after transitioning to the more compact F-controller, the control system still weighed around 30 kg, far too heavy to be fully integrated into a humanoid body—highlighting the need for further innovation.

2019: Untethered Operation and Lightweight Design

By 2019, Kawasaki achieved a major milestone: fully untethered bipedal walking powered by an onboard battery. At this stage:

- Height: 178 cm

- Weight: 85 kg

- External controllers were replaced with compact, high-performance amplifiers and motor drivers

- All electrical components were integrated into the robot’s body

This allowed Kaleido to operate completely stand-alone.

Aggressive Weight Reduction

To achieve this without increasing overall weight, the team focused on:

- Magnesium alloy structural components, lighter than aluminum

- Replacing metal exterior panels with 3D-printed resin parts

- Producing components in-house to dramatically accelerate prototyping

Countless incremental weight-saving refinements followed. Some components became too fragile and had to be reinforced again, making progress highly iterative. Predicting failure points was difficult, requiring repeated cycles of testing and redesign.

Advanced Walking Control and Custom Force Sensors

With hardware maturing, the focus shifted to walking control. Humanoid robots typically use 6-axis force/torque sensors at the ankles, but commercial sensors were:

- Accurate, but heavy

- Expensive

- Vulnerable to shock damage

For humanoid walking, including steps, stomps, and jumps—Kawasaki needed sensors that were lighter and more durable. As a result, the team developed custom 6-axis force/torque sensors optimized specifically for humanoid locomotion.

2021: Introducing “Friends”

While Kaleido emphasized power and robustness, the Friends humanoid series took a different approach—focusing on a slimmer, more approachable design suited for tighter spaces and potential future roles in daily life and caregiving.

A More Human-Friendly Design

Friends feature soft, curved lines designed to blend naturally into homes and care facilities. A display-based face allows the robot to express emotions through animated eyes, creating a more relatable presence.

The name “Friends” reflects the project’s vision: a robot that can genuinely feel like a companion.

Conversational and Gesture-Based Interaction

In collaboration with Osaka University’s Nagai Laboratory, Kawasaki developed conversational and gesture-based interaction capabilities. Using AI, Friends respond verbally to questions while synchronizing gestures with speech.

At a public event at Japan’s National Museum of Emerging Science and Innovation, Friends interacted with children in the audience—drawing laughter and excitement despite conversational limitations.

2023: Achieving More Stable Walking

By 2023, Kawasaki introduced real-time footstep adjustment, enabling the robot to correct its landing position when balance is disturbed. This advancement significantly reduced fall risk and improved walking robustness.

Looking Ahead: The Future of Humanoid Robots

Robots are increasingly expected to assist with work that is dangerous, dirty, or physically demanding. However, traditional robots excel mainly at repetitive, pre-taught tasks—making unpredictable environments a challenge.

Humanoid robots open new possibilities.

When combined with remote operation, humanoids could perform hazardous tasks at disaster sites or dangerous facilities while human operators remain safe—potentially controlling robots from anywhere in the world. This capability is especially valuable for disaster response, where unstable terrain and secondary hazards make human entry extremely risky.