- IndustriesMachinery & Metal Fabrication

- ApplicationsMaterial Handling

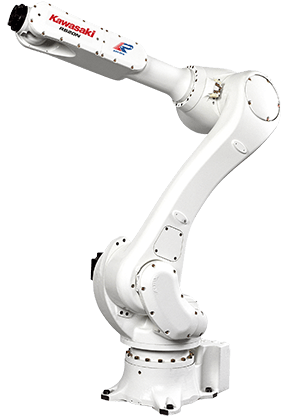

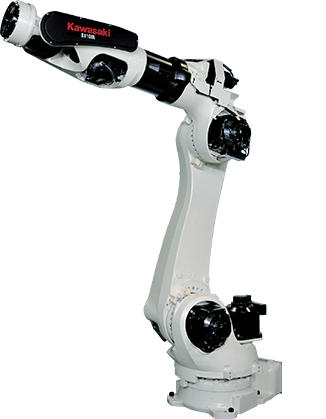

- Robot SeriesR series, BX/BT series

OVERVIEW

As many American manufacturers seek to bring production back to the U.S., industrial robotics can provide the necessary tools to increase efficiency and enhance competitiveness. By automating repetitive and labor-intensive tasks, manufacturers can reduce operational costs and improve productivity, making domestic production more viable compared to overseas options.

Additionally, robotics enable greater quality control and consistent manufacturing processes, addressing concerns about

product quality often associated with offshore production. Implementing robotics allows manufacturers the agility needed to meet consumer demands and preferences, ultimately leading to a more flexible and responsive supply chain.

Kalamazoo, MI-based company Hammond Roto-Finish has a rich manufacturing history, having pioneered many new

innovations in the polish, buff, and mass finishing industry sectors. Hammond Roto-Finish also specializes in robotic

design and integration and was approached by Surface Prep, a trusted distributor of abrasive products and surface

finishing equipment, to design a robust finishing system for a customer currently offshoring production of semi-truck

components.

CHALLENGES

The customer was purchasing and importing fully assembled exterior components developed for semi-trucks. To reshore production of the parts, the customer was looking for two key things:

- Someone who made American products and equipment

- Local customer service and after-sale support

The parts start out as a flat piece of metal and during the shaping process, the radius (the shoulder of the part) between the top and side of the part has very visible lines. The lines are a result of the press shaping the flat plate into a rounded edge. Press shaping is performed multiple times to create the radius. Each press on the part leaves its own draw line (crease line). The first few steps were using a more aggressive media to grind those lines, so the part looks smooth through the rounded edge. The whole part is then buffed to achieve the targeted shine.

SOLUTION

Hammond Roto-Finish and Surface Prep conducted a comprehensive assessment to redevelop the entire production process of these parts. To ensure the parts were finished to the customers satisfaction they also worked with their trusted finishing partner Norton Abrasives, on the polishing portion to get the surface conditioned for buffing and pulling the loose lines out.

When it was determined that robots would be a crucial part of the solution, in a collaborative effort with the customer, Hammond Roto-Finish determined the number and type of robots required, considering this was the first time the customer was deploying robotic automation.

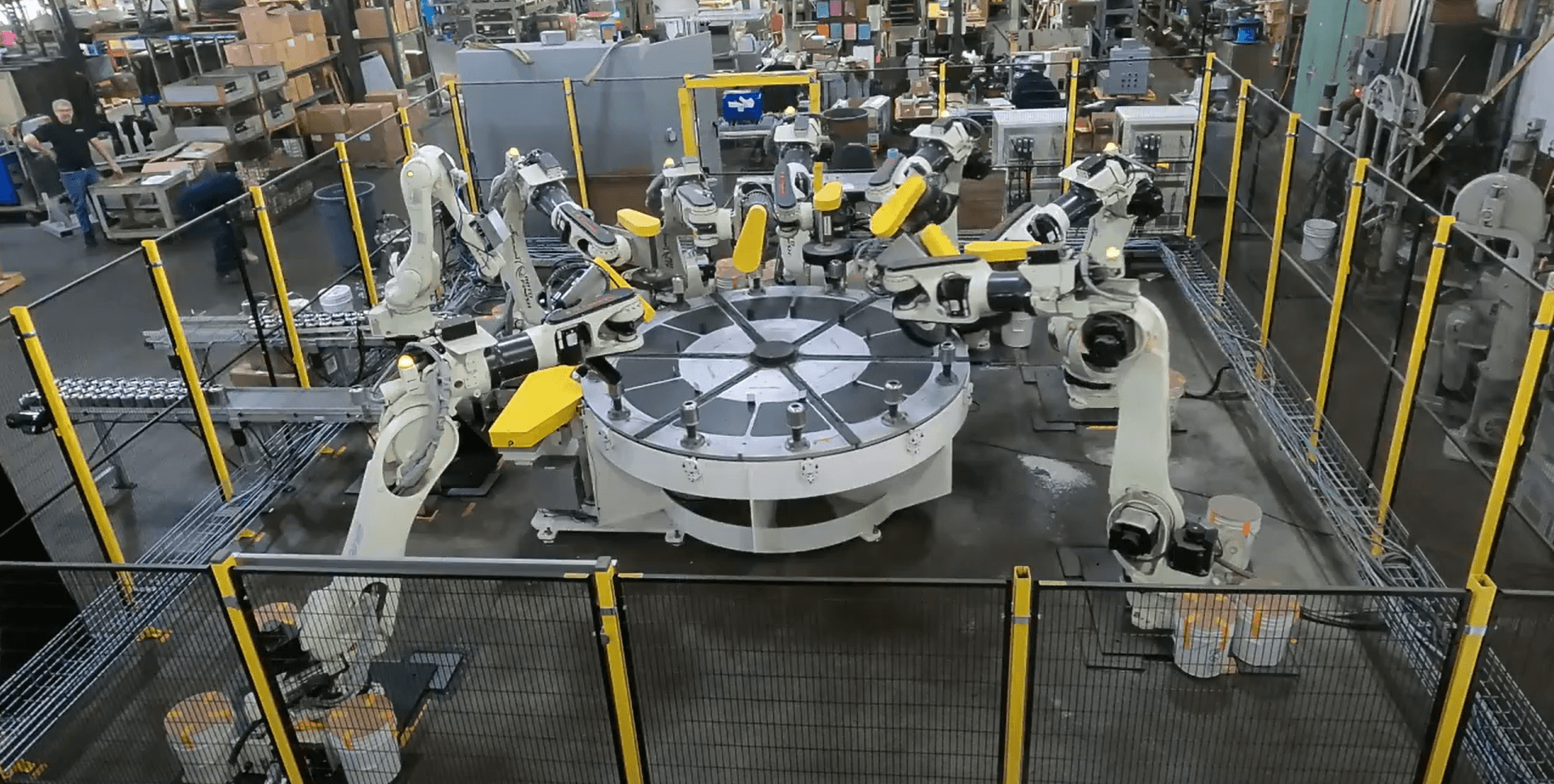

The automated finishing system features an indexing table that allows a workpiece to be rotated to a specific position. Surrounding the table are seven flexible, heavy-duty Kawasaki BX200L industrial robots and a high-speed, high-performance Kawasaki RS020N industrial robot.

The BX200L provides the payload (200 kg) and horizontal reach (2597 mm) needed for this application. The BX200L features a hollow wrist for housing cables and hoses, and the lightweight arm design provides functionality, flexibility, and efficiency to perform two stages of polishing, two stages of buffing, two stages of color buffing, and a clean wipe.

The RS020N is equipped with dual-ended end-of-arm tooling that removes the finished part from the index table and places an unfinished part on the station for processing simultaneously. The finished part is transferred to a conveyor for further handling and packaging.

RESULTS

- Faster Lead Times: Domestic manufacturing shortens lead times compared to offshore production, allowing companies to meet customer demands more quickly and improve responsiveness.

- Improved Quality Control: Producing closer to home enables better oversight, resulting in higher quality standards and fewer defects.

- Reduced Cycle Times: The customer required a KPI of under 15 seconds per part. Each finishing step met this target, and an indexing table with multiple Kawasaki robots ensured a part could be unloaded every 12 seconds, maintaining throughput.

- Consistent, Uniform Finishing: The indexing table allowed parts to move efficiently through multiple finishing stages—outer wall, face, and radius—without the need for separate dedicated stations.

- Smaller System Footprint: A compact layout maximized floor space, leaving room for maintenance access and improving overall operational efficiency.

WORKING WITH KAWASAKI ROBOTICS

When considering Robot OEMs, Hammond Roto-Finish and the customer sought a partner to provide not just the robot but excellent customer service and after-sale support.

“The best benefit we have to working with Kawasaki can be summed up with one word, and it’s responsiveness. When we have questions, and when we have issues, we need an answer, and we need it quick. When you’re building an incredibly sophisticated systems for customers that are demanding they be right, that is such an important part of the partnership.

Phil Hammond

Hammond Roto-Finish