Kawasaki Robotics, AI, and deep learning: Freiburg-based system house has developed a forward-looking combination for complex tasks and smallbatch sizes

After Marco Arnold founded Arnold IT in 1997, the system house quickly became a sought-after expert in digitization, automation, and Industry 4.0. Numerous customers in Germany and more than 20 other countries use customized solutions and comprehensive consulting and services from the Freiburg-based company. In recent years, Marco Arnold has observed a key question, particularly among small and medium-sized enterprises: How can artificial intelligence, with all its advantages, be successfully and precisely integrated into production processes in a more accessible way?

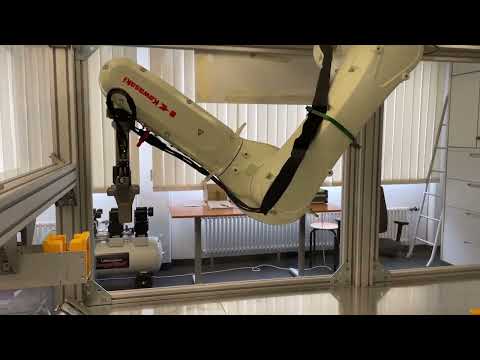

For the owner and managing director, one thing is clear: “We don’t just want to provide our SME customers with targeted support in automating their production and integrating AI – we want to give them access to it and make it easier for them to use.” In 2024, Arnold and his team developed a versatile robot cell that combines state-of-the-art automation hardware with AI-supported camera systems. Flexibility was the main focus: on the one hand, the cell should be equally suitable for series production and small batch sizes. On the other hand, it should function as a turnkey solution, but also as an open and easily adaptable system.

Kawasaki Robotics impresses with speed and precision

The search for the right robot manufacturer for the project was long and careful, but in the end, the choice was easy, according to Marco Arnold: “We examined all the options closely, but Kawasaki simply impressed us across the board. The RS series robots are not only extremely fast, but also offer a particularly high level of repeatability, which is crucial in industry and many processes. Of course, the good price also played a role, but especially the numerous options included, along with excellent service and advice.”

The technology based on autonomous, vision-guided robots is the key to extreme efficiency, flexibility, and precision in production. The Kawasaki RS007N used in the cell can thus automatically process components and assemblies at the highest level. The limitations of conventional image processing are no longer an issue for Marco Arnold: “Image processing has been commonplace in robotics for a good 15 years, but AI opens up completely new possibilities and is easier to use than ever before.”

The cell was developed for numerous industries, including plant and mechanical engineering, construction, food production, sanitation, and clothing. In addition, its automatic part recognition enables it to perform a wide range of tasks effectively: from analysis and handling to assembly and machining—such as milling, grinding, or drilling workpieces. The system has already impressed the German Federal Ministry of Education and Research: in 2024, the BMBF selected Arnold IT’s innovative solution for a research contract and funding.

Intuitive automation with AI and deep learning

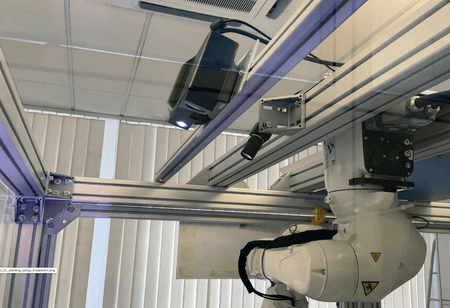

The intelligent pick-and-place cell works in a simple way: a 3D camera integrated into the system captures the objects to be processed. The data is immediately transmitted to the robots via PLC so that they can start processing. The AI immediately detects the correct position or errors in the workpieces.

This makes autonomous collaboration between multiple robots a breeze: the first robot picks up the part and presents it to the 3D camera. The AI interprets the data and sends the necessary information to the interface. The first robot then transfers the object to the second robot, which performs the necessary processing steps. Even objects with very different properties are reliably captured and brought to the desired state.

The arm structure and low weight of the Kawasaki RS007N’s main unit enable a high working speed, even in demanding and confined environments. Particularly practical: synthetic training data for new product series can be processed before production begins, saving considerable time. The Arnold IT solution is designed for progress: it continuously learns through deep learning methods and independently familiarizes itself with new tasks.

Outlook

In addition to the BMBF, the AI-supported cell has already convinced several customers and is being used in a number of production facilities. Marco Arnold and Kawasaki Robotics continue to have big plans: “We want to provide our customers with a smart, digital assistant that uses AI to learn tasks independently. We are proud of this solution, but we are working on making it even more intuitive and intelligent, as well as making it accessible to many other industries.”