Pulseboard inspection system

how does pulseboard work?

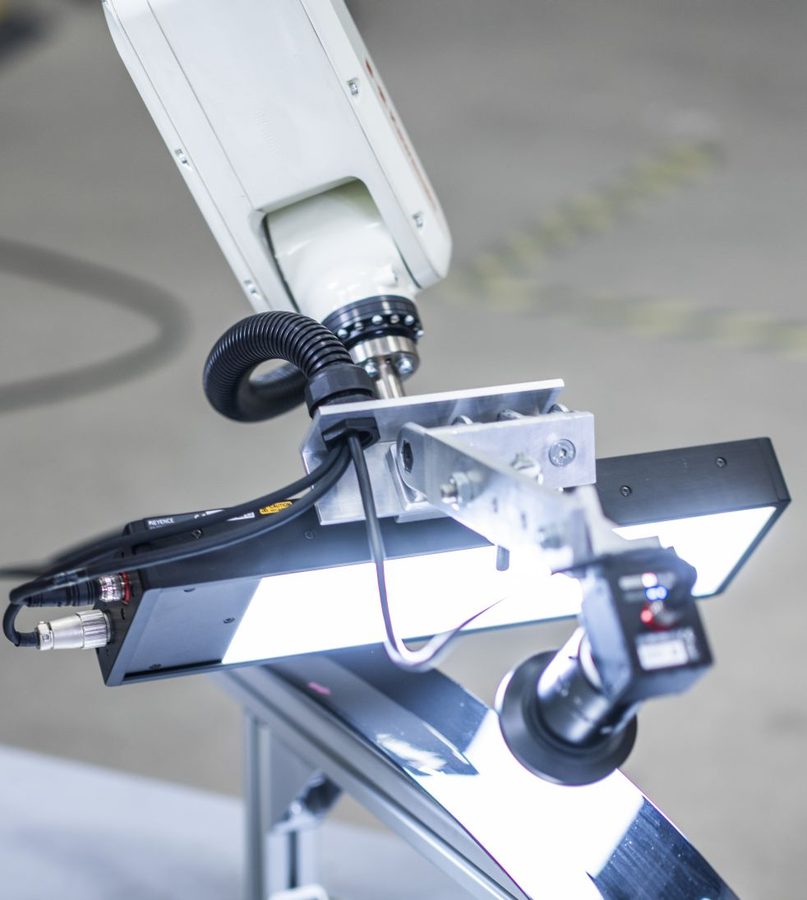

Our Pulseboard technology works like a scanner for shaped parts. Our very different approach of using a line camera instead of an area camera makes this possible. What is the difference?

Area Camera: A large number of individual images is required to avoid distortion and the robot needs to stop for each one – resulting in a time-consuming process for pictures that allow proper inspection.

Line Camera: Similar to a traditional scanner, it produces a single image by triggering the camera in real time and many short intervals. Our Pulseboard is the only technology on the market to provide fast enough processing to do so – regardless of path, speed and acceleration.

Speed is the Name of the Game

From starting up the system to the inspection itself: Pulseboard is as fast as it is easy to use:

Scan complex surfaces like you are using a copier: Imaging can be performed without worrying about the speed of the robot by issuing an imaging trigger according to the amount of movement of the tool tip. Therefore, the complex surface can be scanned simply by teaching it to follow the curved surface.

Fast cycle time: Since it is possible to image along a curved surface at high speed, the cycle time is 1/10 compared with an area camera.

Fast start-up: Since there are few teaching points, the start-up is 1/6 faster! Teaching points can be reduced compared to area cameras (from 140 to 25 points).

Your Advantages with pulseboard

The curved surface inspection is realized within a space of no more than 2 m²

Space saving: The appearance inspection of the curved work is possible with! The camera is fixed and the workpiece is handled while the exterior inspection is carried out to realize the curved surface inspection even in a very small workspace (2×1 m).

High speed: Small and high curvature work can be inspected at high speed! By continuously taking images along a curved surface and composing the images, the number of images taken is less than that of an area camera (1/3), and even small and high-curvature workpieces can be inspected at high speed and appearance inspection can be performed.

OK Items and NG Sorting items is possible: By handling the work and inspecting its appearance, it can handle sorting of OK and NG products.

Pulseboard RESOURCES

what is included? what else do you need?

Our Pulseboard System includes:

- Versions for both our F60 and F0X controllers

- The Pulseboard hardware, installation material for controller, coordinating table for output function

- (Optional) Finger Pulse Harness: 5m, 10m, 15m, 20m

- (Optional) Fixed work point operation function (Part moves around the camera)

What do you need to get started?

- The Kawasaki Robot of your choice

- Image Processing Unit/ 3D Viewer

- Camera which can input a pulse signal and use it as external trigger

- Lighting