Automatica 2025

european premiere

From June 24 to 27, 2025, Kawasaki Robotics will be presenting numerous new products and solutions at Automatica in Munich (stand A4.321) – including extensions to the Cobot Series, the RF007L food robot, the MXP Series for heavy loads and new additions for pharmaceuticals and metal processing. On 180 square meters we will present not only new robot models, but also practical applications for numerous industries. Shuhei Kuraoka, President of Kawasaki Robotics EMEA, says: “We are delighted to present the next generation of our high-end industrial robots and cobots as well as innovative automation solutions to visitors to Automatica 2025 for the first time.”

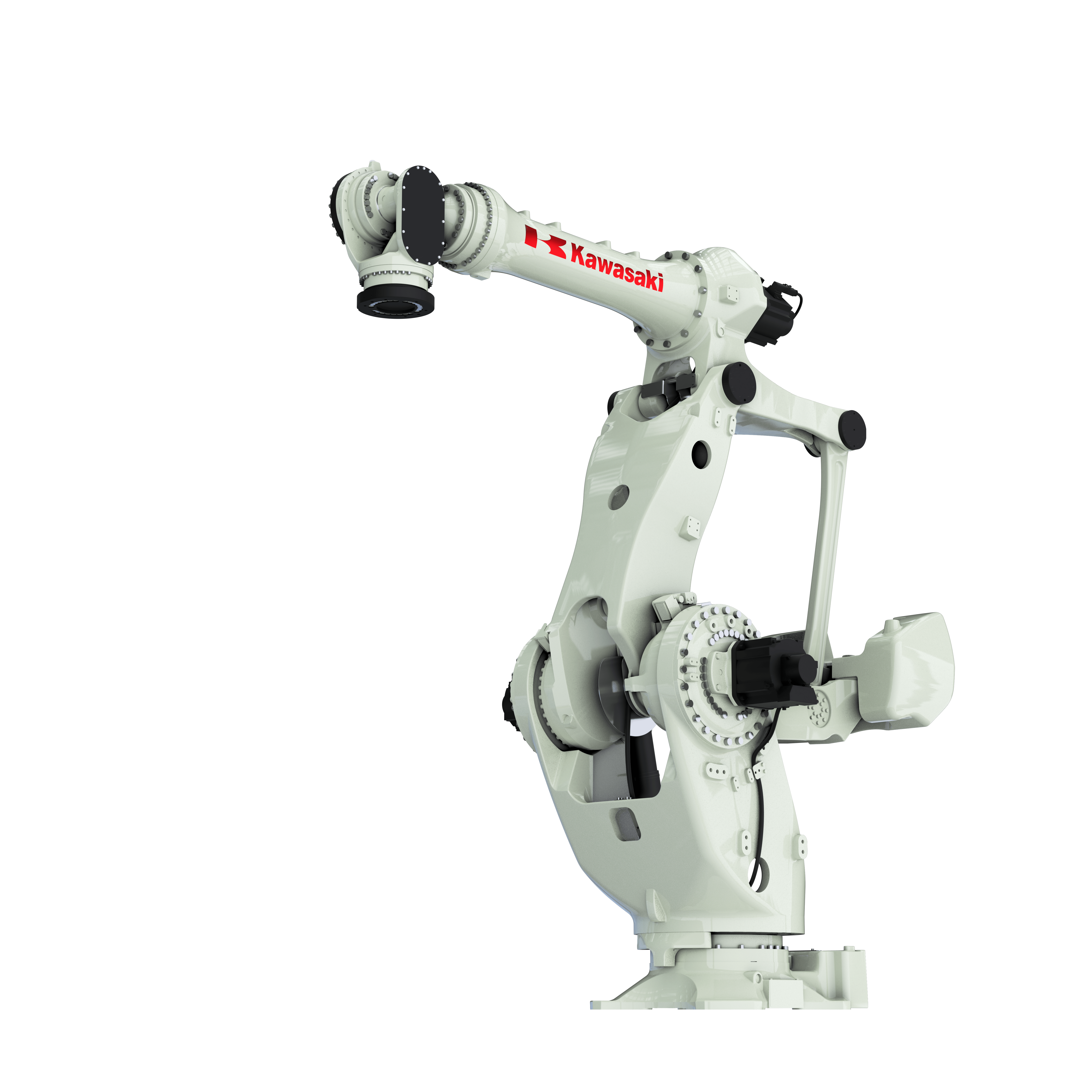

new models revealed

The MXP710L – the flagship of the new MXP series with a load capacity of 710 kg and a minimal footprint – will take center stage at the trade fair. The further development of the successful MX series is 41 percent lighter and significantly more compact. Thanks to its unique hybrid link design, the MXP series still offers a large movement range and up to 21 percent shorter cycle times. As a special highlight, the robot will be lifting the brand new 2025 BRUTE FORCE 450 T-CAT ATV from Kawasaki Motors at Automatica. With the BA013N and BA013L models, Kawasaki Robotics is presenting a further development of the popular BA series for arc welding. The increased stability and vibration reduction ensure optimum welding results. In terms of load capacity, working range and speed, the two models are among the best on the market. The internal cable routing now also offers more space for all welding equipment.

Highest hygiene standards for pharma and food

Specifically developed for the high standards of the pharmaceutical industry and work in isolators, the MC006V not only offers the highest performance, but also a full stainless steel surface and special seals. It features an improved hygienic design with simplified geometry and a new, improved chrome plating that offers greater resistance to a wider range of chemicals and mechanical damage/impacts. The working speed is among the best in its class.

The RF007L food-grade robot is based on the best-selling RS007L and is certified for primary food handling by the Fraunhofer IPA, among others. Chemical resistance and the highest hygiene standards are also guaranteed by the stainless steel flange and additional synthetic resin seals on the joints, which effectively prevent the ingress of foreign bodies.

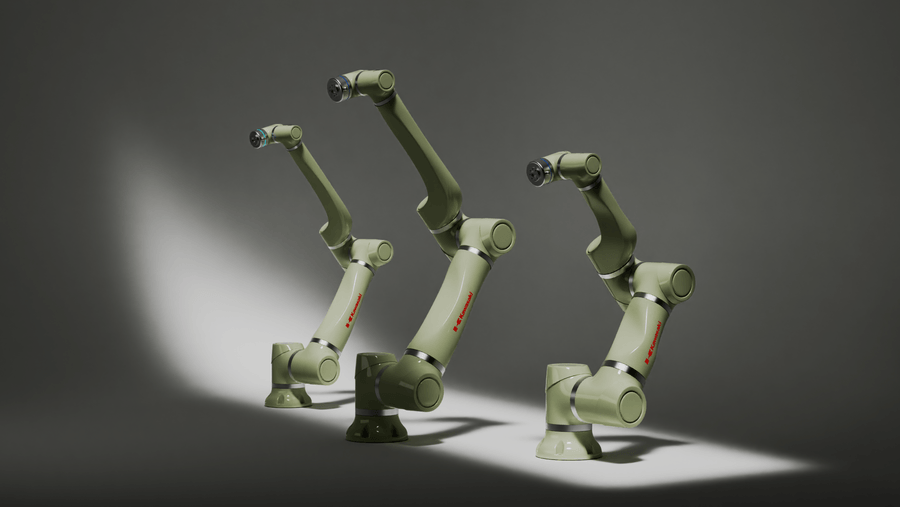

The next generation of cobots and more

Visitors to the trade fair can also experience further developments of the CL series cobots live: These include an extremely fast and easy-to-use bin picking application in collaboration with Mech Mind, as well as a demonstration of the CL series’ extensive arc welding capabilities. With the CL130L, Kawasaki Robotics will also be presenting the next generation of its successful cobots: Four new models with a payload capacity of up to 30 kg, the usual simple operation and new smart features.

In addition to the new robots, Kawasaki Robotics will also be presenting the latest generation of controllers, the F0X B-Type: The smallest and lightest controller for medium-sized robots is not only compact, versatile and intuitive to operate, but also impresses with maximum energy efficiency thanks to an innovative regenerative system. Other highlights include the innovative Pulseboard surface inspection system, which Kawasaki Robotics is presenting together with its long-standing partner Zeiss, the new and extremely intuitive NeoROSET OLP tool, numerous new options for the ASTORINO education robot and much more.