Wixom, Michigan, Sepember 4, 2025 – Sparks will fly at FABTECH 2025 in Chicago as Kawasaki Robotics turns up the heat with live robotic welding, next generation cobots, and powerful partnerships that prove the future of metal fabrication is faster, smarter, and more accessible than ever.

Under the theme “Unleash the Spark” Kawasaki will showcase hands-on welding demos, new collaborative cobot weld carts, and the compact, high-precision VeloWeld™ Velo-S Cell. Attendees can even bring their own part (≤40” in diameter) and watch it welded live on the show floor—real sparks, real results, real proof of performance.

New Innovations: Cobots & Weld Carts Built for the Shop Floor

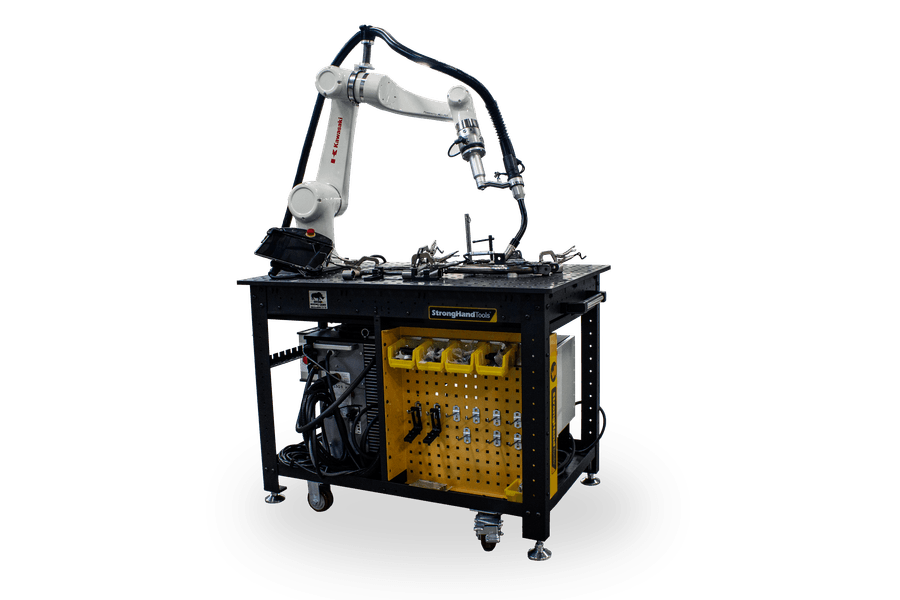

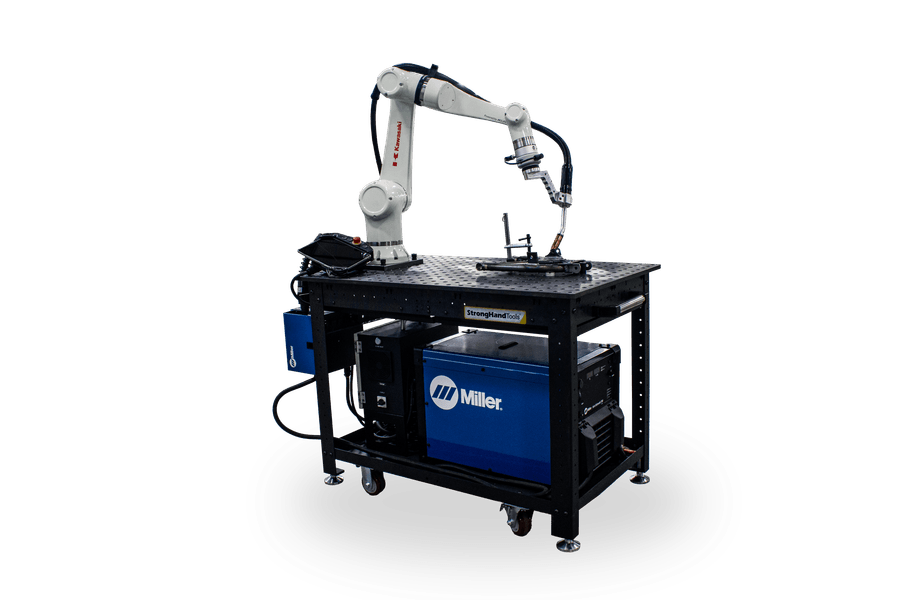

Kawasaki’s new CL Series Cobot Weld Carts bring industrial-strength collaboration to fabrication shops of all sizes:

- Efficiency & Productivity – Automate repetitive welds, boost uptime, and drive throughput.

- Easy Teach Programming – User-friendly interface that requires no prior robotics experience.

- Safety-First Design – Collision detection and speed controls allow true human-robot collaboration.

- Shop-Ready Customization – Compatible with leading welding supply brands (Miller, Lincoln Electric, ESAB, SKS).

Packages Include: Strong Hand Rhino Carts and 66-pc. Fixturing Kit, full weld packages, and Kawasaki’s CL Series cobots (CL108N, CL110N, with the CL115N launching soon), and Easy Teach module, starting at $75,000.

Partnership Power: VeloWeld™ & Wauseon Machine

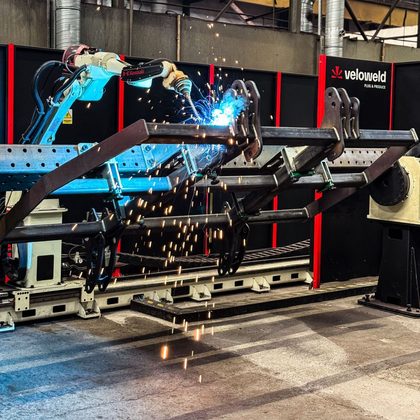

Kawasaki is joining forces with VeloWeld™ and Wauseon Machine to deliver flexible, high-performance welding and end-forming cells.

On display at FABTECH 2025:

- VeloWeld™ Velo-S BA006L Welding Cell – Compact, plug-and-produce system with Kawasaki’s BA006L robot, dual-axis positioner, and Fronius 400i MV power source. Designed for large part manufacturers, it’s proof that big weld performance can come in a small footprint.

- Wauseon Machine End Forming Demo – Kawasaki CL015N cobot tending a Wauseon 1004EL Electric End Forming Machine for precision tube handling and forming.

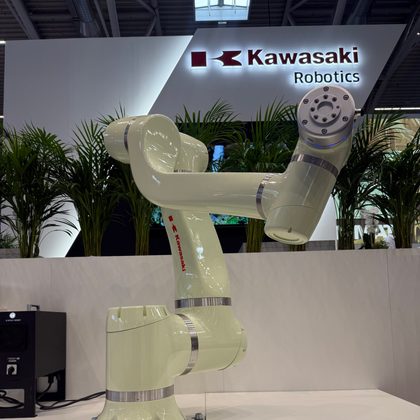

Sneak Peek: Next-Gen Kawasaki CL130L Cobot

FABTECH attendees will get an exclusive preview of the Kawasaki CL130L, launching in 2026. This next-gen collaborative robot boasts:

- 30 kg payload capacity

- 1,800 mm reach

- IP66 Rating

- Advanced safety systems for heavy-payload collaboration across industries from automotive to aerospace.

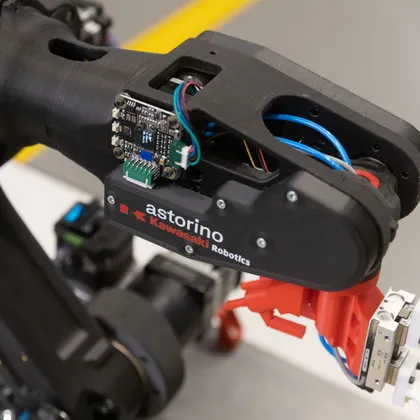

Education & Training Spotlight: The Astorino

Kawasaki will also highlight the Astorino, a 6-axis, 3D-printed educational robot designed for schools and technical training providers. Affordable and programmable with Kawasaki’s AS Language, it’s a hands-on way to prepare the next generation of fabricators and robotics technicians.

Show Exclusives & Giveaway

- Buy the Velo-S demo cell at FABTECH → get FREE commissioning + operator training.

- First attendee to cut a PO at the show → receives a bonus installation package.

- Hands-on demo of Kawasaki’s new F0X controller & teach pendant → chance to win FREE onsite consultation or robotics training.

Visit Kawasaki Robotics at FABTECH 2025

McCormick Place, Chicago, September 8-11, 2025

Booth #B15001

Don’t just watch a demo. Bring your part. Watch it get welded. Believe the difference.

About Kawasaki Robotics

With over 50 years of experience in the automation industry, Kawasaki Robotics is a leading supplier of industrial robots and robotic automation systems with expertise in a wide range of applications and industries. The company delivers the best-value robot offerings by providing a rich set of standard features on all models for application flexibility, renowned Kawasaki quality and performance, and unmatched customer support and after-sales service. Learn more about Kawasaki Robotics here, watch robot application videos here, and connect on Twitter, Facebook and LinkedIn