Reduce Labor Costs by Automating Material Handling Tasks

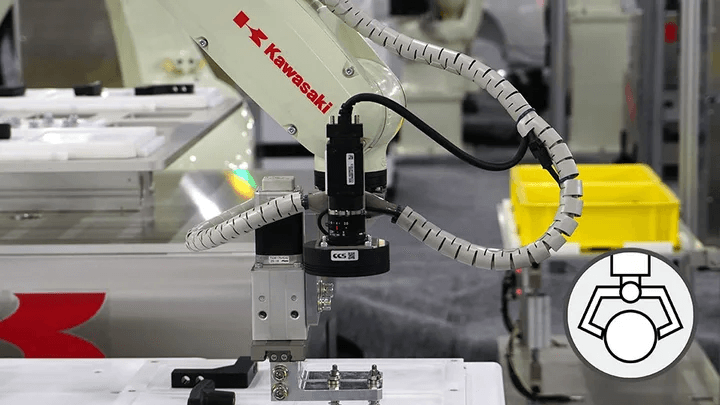

Material handling (MH) makes use of the robot's simple capability to transport objects from one place to another. By fitting the robot with an appropriate end of arm tool (e.g. gripper), the robot can efficiently and accurately move product to different locations. Kawasaki offers both products and services to solve a wide variety of material handling challenges.

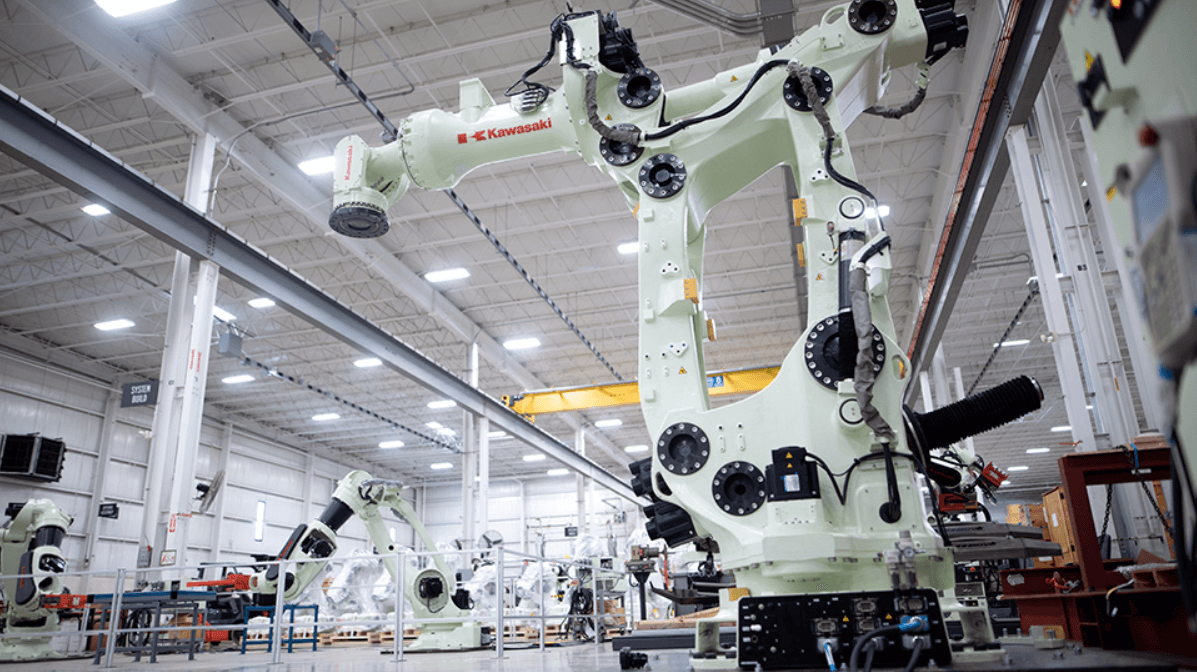

Kawasaki's material handling robots can eliminate the requirement of hazardous, tedious, or fatiguing labor in an industrial environment. The list of Kawasaki MH robots include 52 models ranging from 2 to 1500 kg payload capacity. Kawasaki robot controllers offer many options to aid in MH applications, including conveyor tracking, collision detection, and servo controlled end of arm tooling. These MH robots can interface with other equipment such as containers, conveyors, guided vehicles, automated storage/retrieval systems, and carousels.

Kawasaki offers an extensive line of robot models and software to fulfill your automated material handling needs.

Application Video

Robots for Material Handling

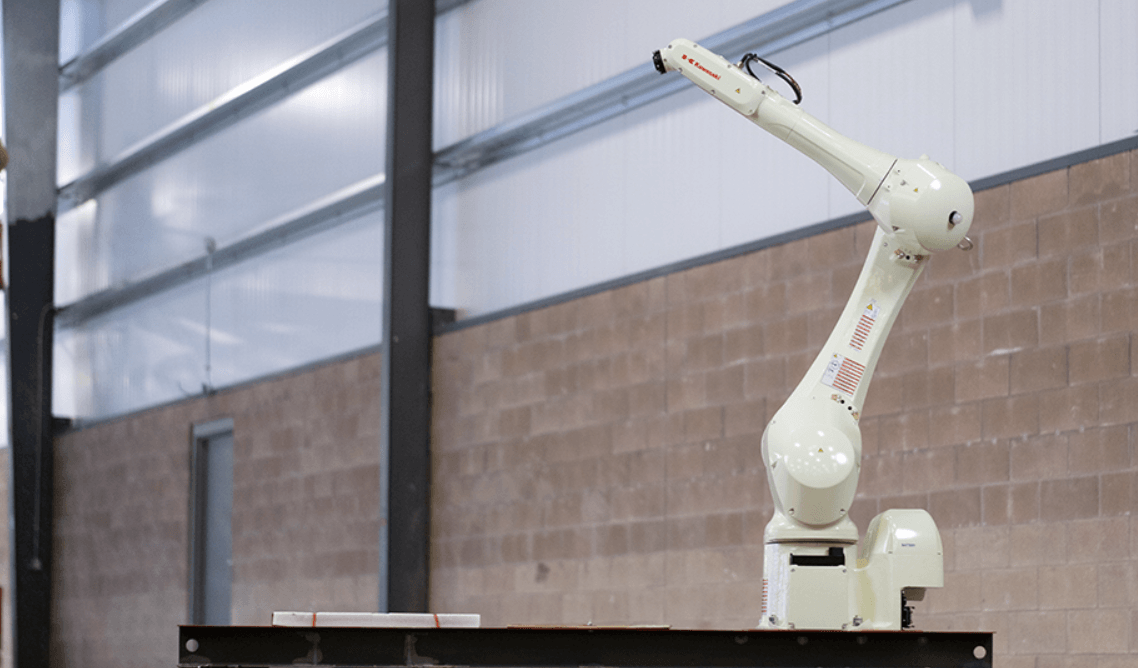

General Purpose Robots (3-80 kg payload)

Our general-purpose R series robots set the benchmark for small-to-medium duty industrial robots.

General Purpose Robots (100-300 kg payload)

Flexible, heavy duty, general-purpose robots with large payload capacities.

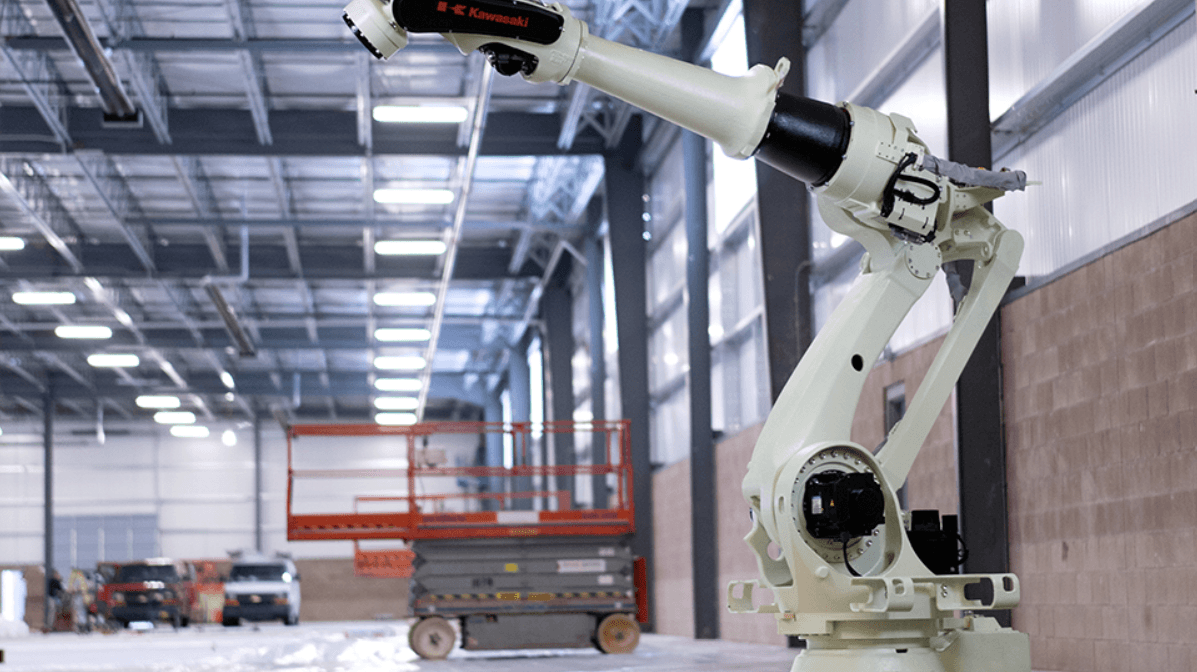

General Purpose Robots (350-1500 kg payload)

Our innovative design gives these models the power to lift heavy loads with ease and accuracy.

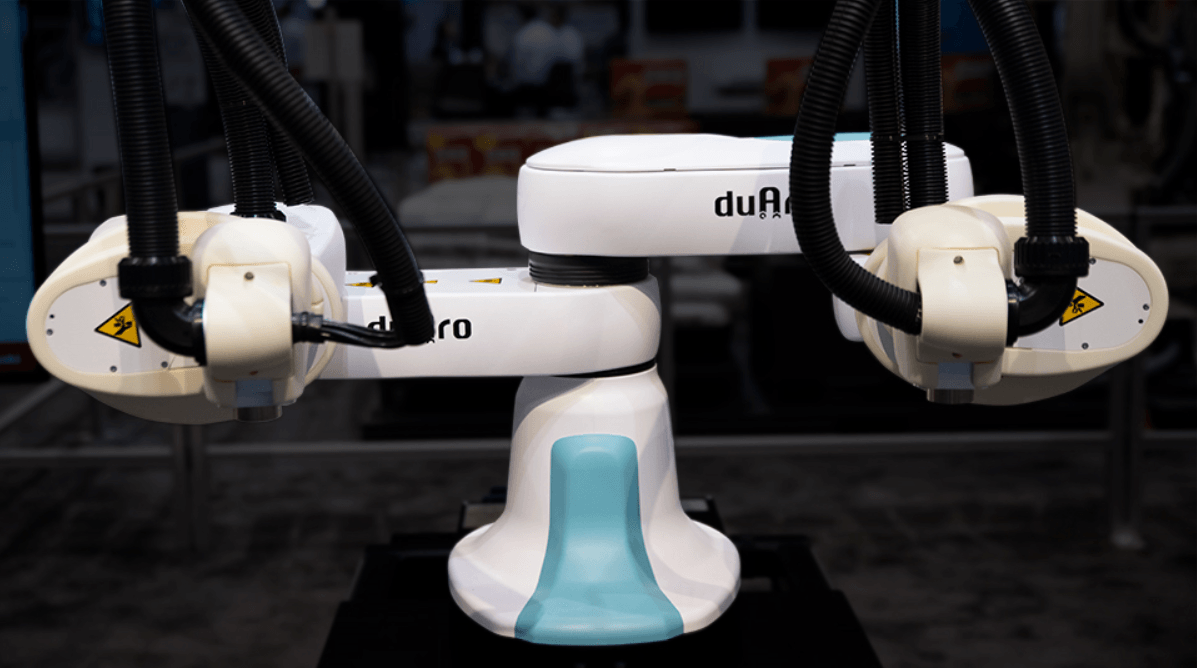

Dual Arm Collaborative Robots

Kawasaki’s unique dual-arm SCARA cobot can collaborate with and work safely alongside humans.

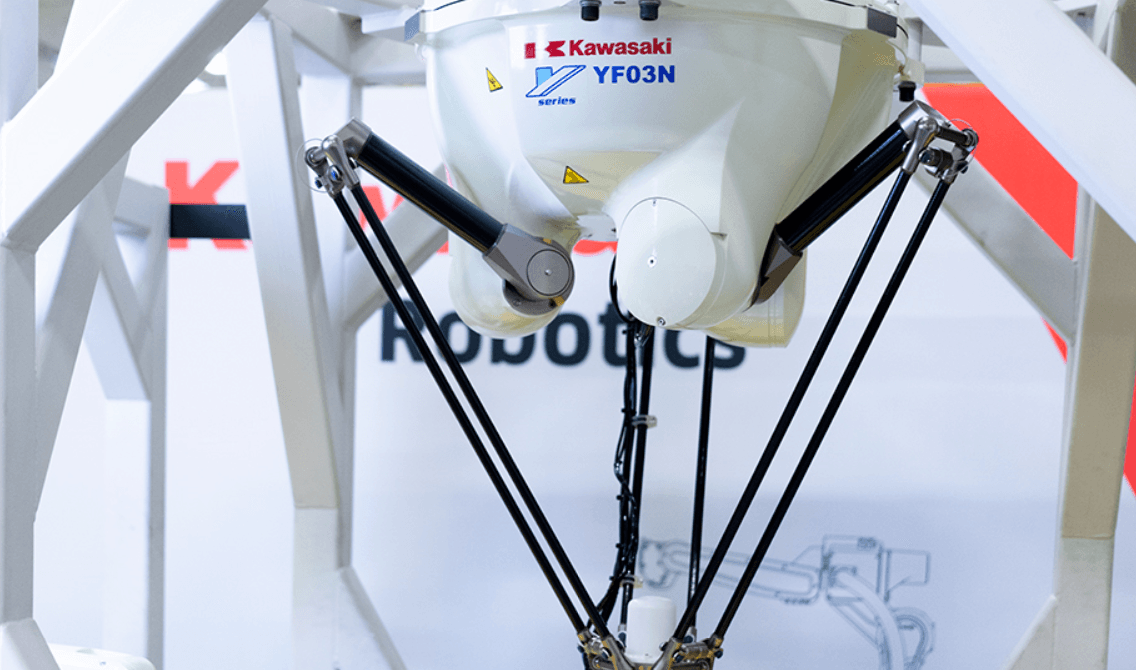

Pick & Place Robots

Flexible food-grade robots that pick and sort small parts and products at ultra high speeds.

Collaborative Robots

CL Series Collaborative Robots

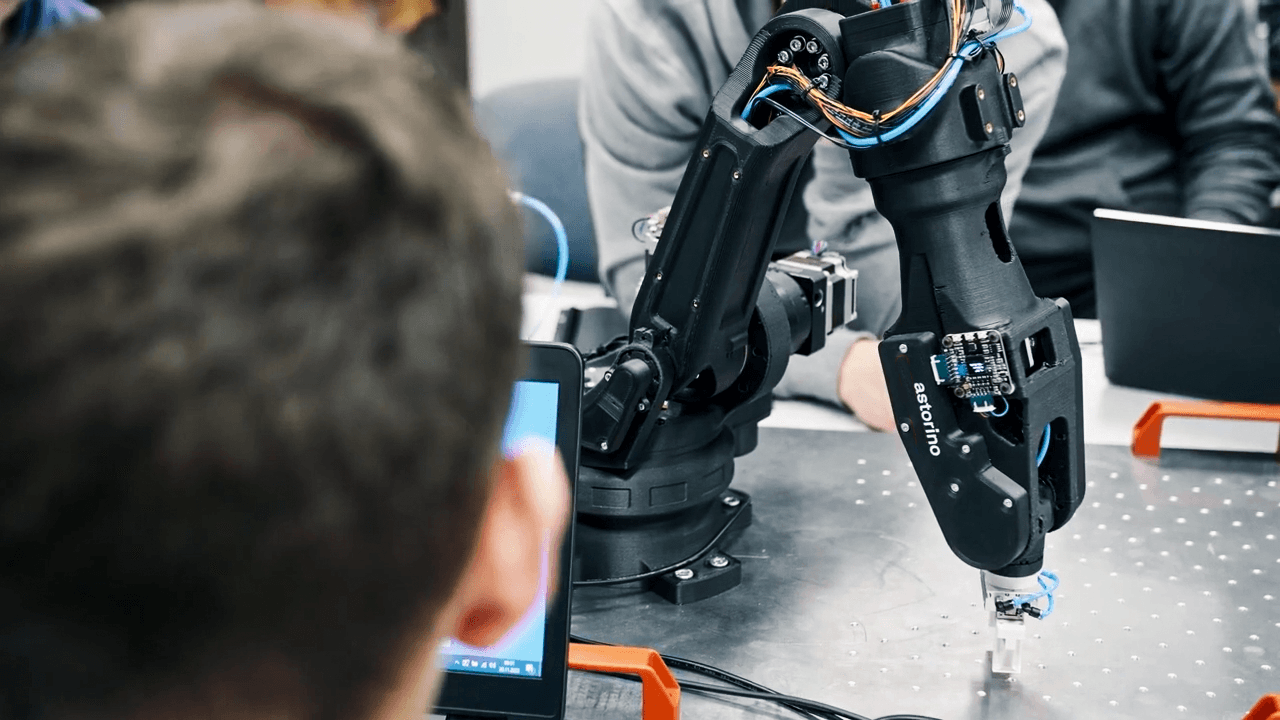

Educational Robots

Embrace the future of industrial robotics education with the Astorino. A unique and remarkably affordable educational robot for North American industrial/technical education providers.