MaterIAL REMOVAL

Robots

What is ROBOTIC MATERIAL REMOVAL?

The purpose of material removal or finishing robots is to automate tasks such as deburring, grinding, sanding, polishing, cutting and surface finishing to name a few. These robots are most deployed in a fully automated system and equipped with specialized end-of-arm tooling. The automated system may also include force control sensors, vision, or compliant tools to be able to adapt to various surface textures, part shapes, and required quality finishing standards.

Material removal or finishing robots are often used to process plastic, metal, wood, and composite parts in industries like aerospace, automotive, metal fabrication, and consumer goods manufacturing. Robots are extremely useful for these types of applications as they help ensure precision, repeatability, and consistent surface quality while reducing labor costs and improving operator safety.

How Manufacturing Companies Can Overcome MATERIAL REMOVAL Challenges

Manual material removal and finishing can present several challenges for manufacturers still reliant on manual labor. Oftentimes, it is difficult to control quality due to human variability, leading to uneven finishes and rework. Finding skilled labor to perform these tasks is becoming increasingly complex, and there are potential risks to the workers involved. Manual material removal processes are often labor-intensive and challenging to scale, causing throughput bottlenecks that cannot handle increased demand.

With robotic automation, manufacturers can increase throughput while delivering more consistent results. It reduces the reliance on manual labor while increasing workplace safety.

With robotic automation, manufacturers can increase throughput while delivering more consistent results. It reduces the reliance on manual labor while increasing workplace safety.

The Kawasaki Robotics Difference

Kawasaki Robotics offers advanced robotic material removal solutions designed to deliver precision, consistency, and control across a wide range of applications.

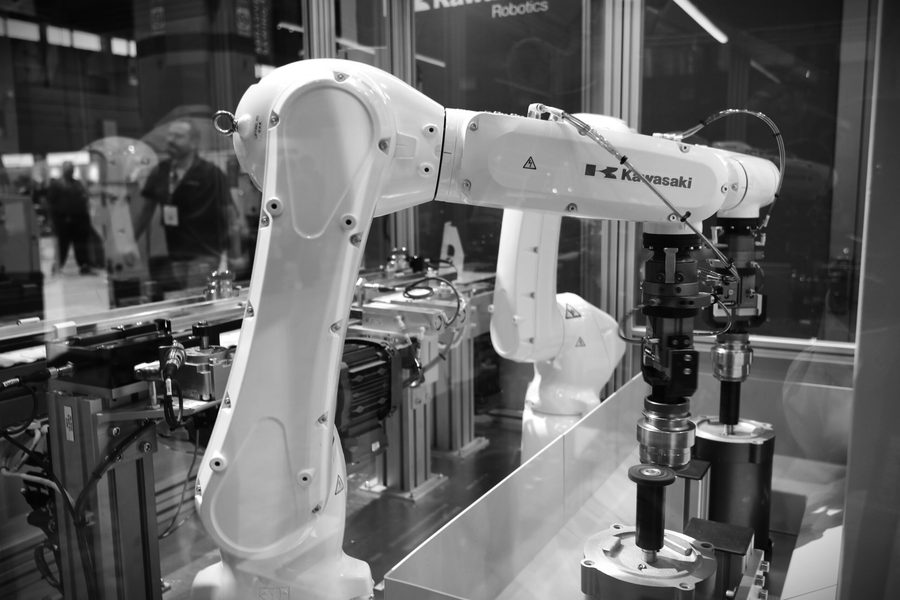

Our innovative software features force feedback control to ensure the optimal amount of pressure is applied between the robot and the workpiece—protecting surfaces while enhancing finish quality. We also offer motion coordination between multi-axis positioners and robots, enabling smooth, accurate movements even in the most complex material removal tasks.

Whether you’re grinding, sanding, deburring, or polishing, Kawasaki Robotics can help provide customizable material removal systems tailored to your specific manufacturing needs. Our standard robot controllers come fully equipped with built-in communication options for seamless integration with your existing material removal equipment.

When you work with us, you won’t find hidden and costly surprises for added software capability, product manuals, training, remote service calls and more. As we are committed to being your partner in achieving automated material removal solutions that improve product appearance, boosts consistency, and enhance overall production quality.

material removal robot RESOURCES

Case study: storage tank manufacturer automates

Case Study: AMT Dual RS080N Material Removal & Finishing

HOW WE do RobotiC MATERIAL

REMOVAL DIFFERENTLY

Whether you aim to reduce labor costs, improve part quality, or optimize tooling costs and minimize scrap, we can help. Backed by an integration network and decades of real-world application experience, our material removal and finishing solutions, whether a single manual deburring station or a fully automated multi-robot finishing line, are engineered for industrial environments, easy to integrate, and built for scale.

- Our robot software allows for both automatic quick-change tooling and servo-controlled end-of-arm tooling.

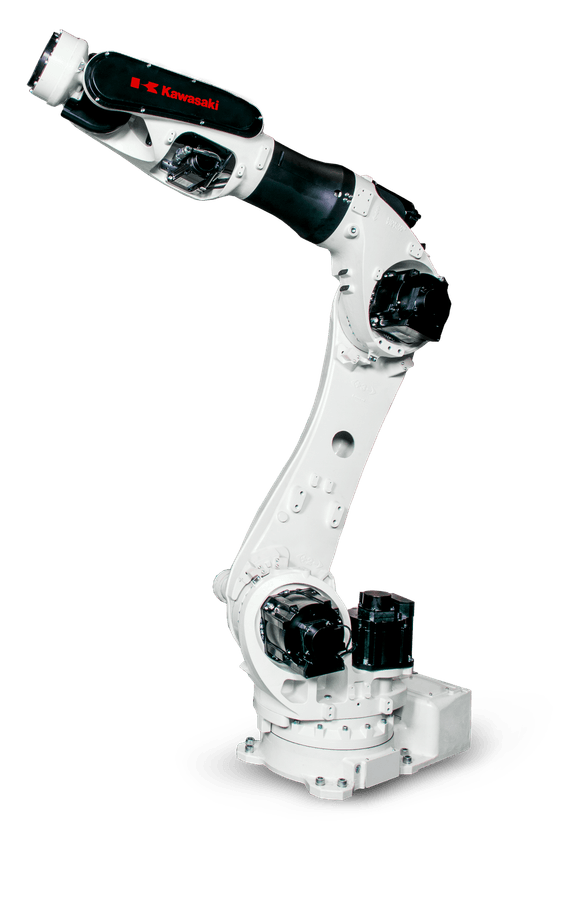

- Force/Torque sensors and compliant end-of-arm tooling can easily be integrated with our robots to ensure surface quality and consistency.

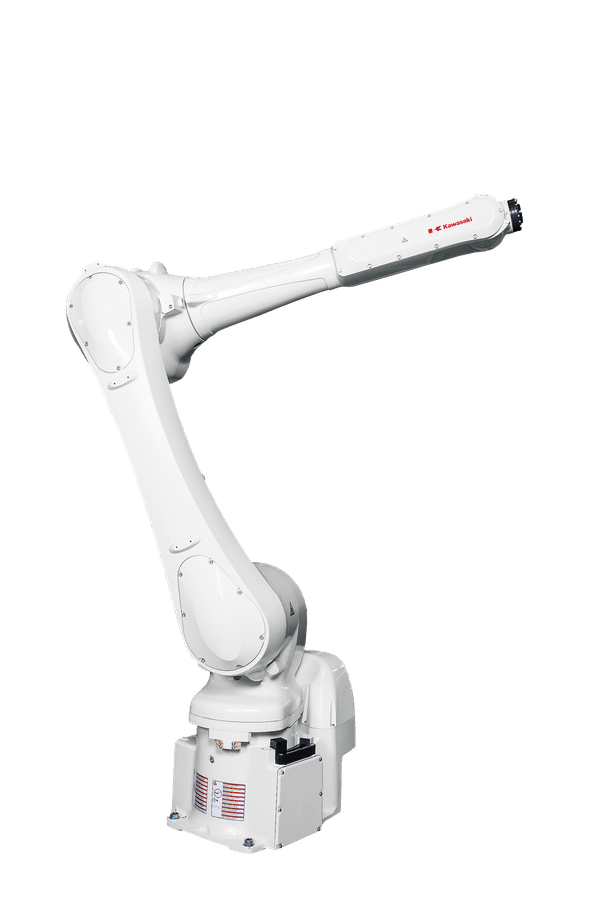

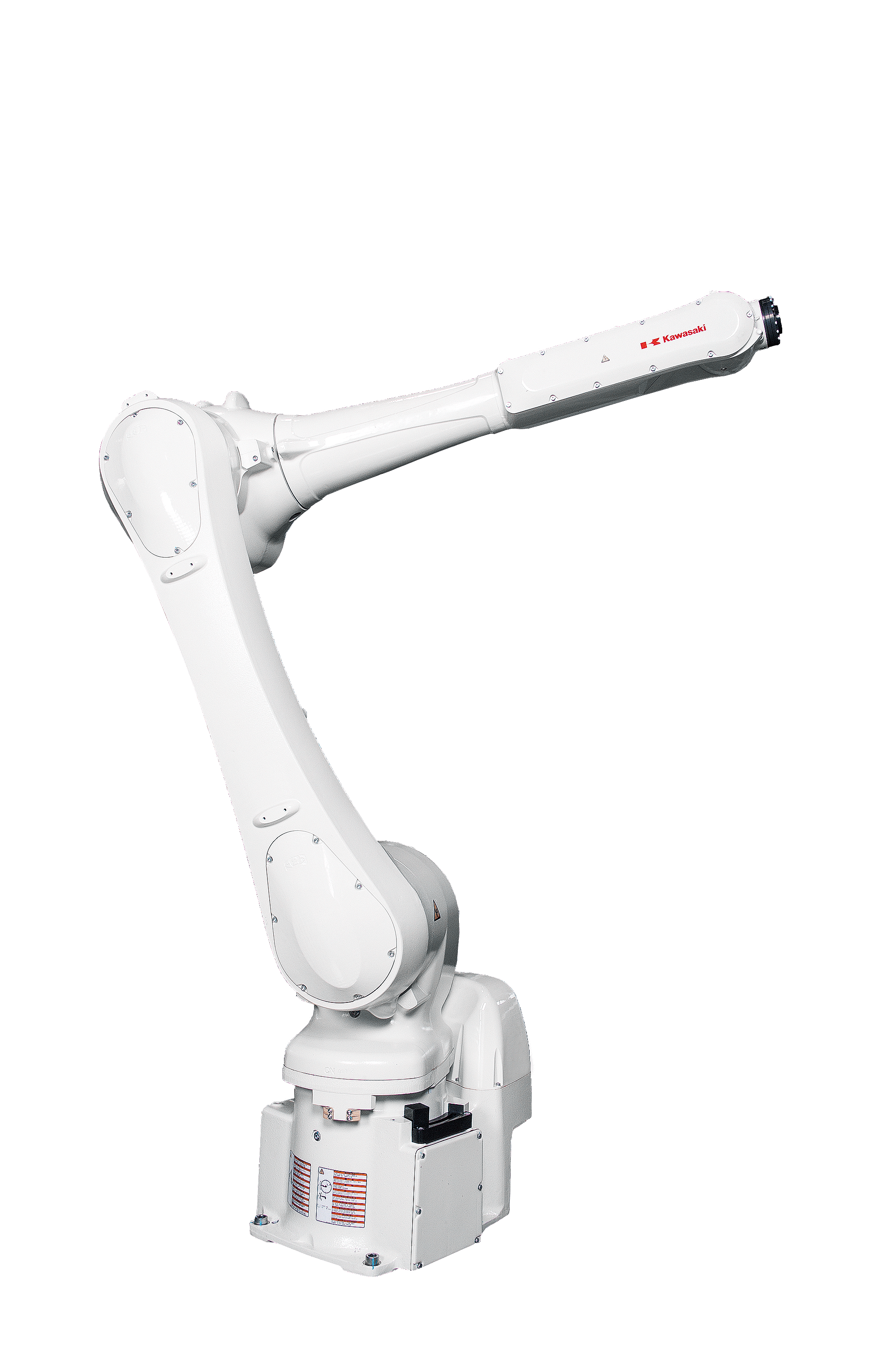

- Industrial-strength, high payload & extended reach robots are available for processing large complex parts or integrating multiple finishing steps into a single work cell.

- Kawasaki robots are engineered to withstand any environment that produces dust, debris, or abrasive wear.

- Kawasaki’s controllers enable seamless multi-axis motion coordination and offers standard interfaces for communication with peripheral equipment

- Our robots can be programmed using simple Block Step style programming.

- Or, for more logic-intensive work, the full Kawasaki AS programming language is yours.

ROBOTIC MATERIAL REmoVAL IS BETTER WITH KAWASAKI ROBOTICS

Our robots, paired with our open architecture software, allow us to be genuinely technology agnostic, which means we can select the best machine vision and end-effectors needed to complete material removal tasks while maintaining the highest standards of accuracy and precision.

At Kawasaki Robotics, we don’t just sell hardware. We provide comprehensive through-life support and services, backed by our proven and productive hardware, open architecture software, and technology-agnostic stance. This level of support is a rare find in the industry, and it’s our commitment to ensuring your success

Our extensive network of integration and technology partners allows you to harness the power of our comprehensive software suite. Whether you require a simple or complex solution, our suite, which includes AI capabilities, has you covered. And the icing on the cake: Kawasaki has inventory available. You get industry-best lead times on delivery, followed by complete freedom to develop exactly as you want to.