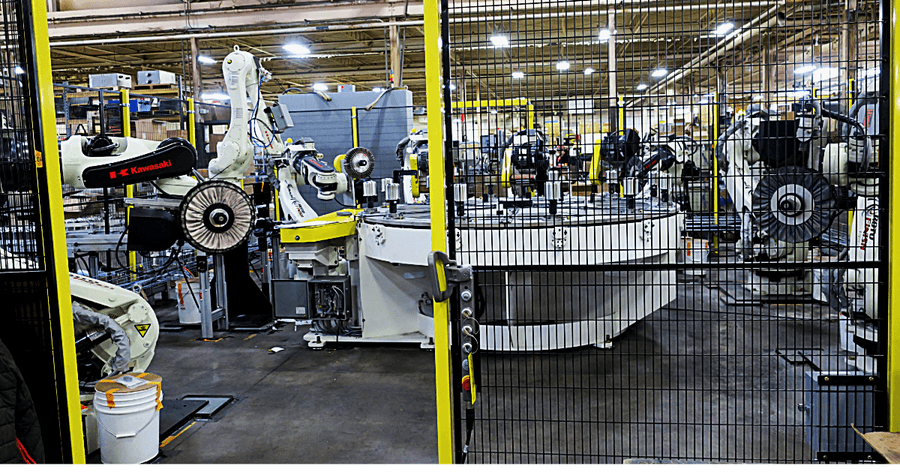

By Zachary Thoma, Regional Sales Manager at Kawasaki Robotics

I encounter this question often enough over the course of my week that I figured I’d park it in the chair and write a full guide. If you’re wondering what the difference is between fixed automation and flexible automation—and which is the best fit for you—get ready to scroll for a bit.

What Is Fixed Automation?

Put simply: fixed automation, also known as hard automation, is automation without a robot. It covers anything that is generally not flexible to changing orientation, adapting for multiple SKUs, or programmable as a single unit.

Instead, fixed automation is a system using servos, standalone servers, linear or rotary actuators, separate sensors, and programmable logic controllers (PLCs) all integrated into one system.

Benefits of Fixed Automation

Want to go fast above anything else? Fixed automation is for you. It tends to be faster than any other option. We robotics folk don’t love to admit that it’s faster than robots, but it’s true. Go to tradeshows and see actuators, they’re moving at wild speeds. I’m talking sub-one second cycles.

On top of the speed, actuators and servos are available and relatively cheap. A lot of foot-printing is standardized as well, and it’s easy to plug & play with a lot of different fixed automation components.

A couple more perks while we’ve got momentum: simplicity and robustness. A good PLC programmer doesn’t have to break a sweat to get fixed automation doing what it needs to do. It’s not overly complex. And in terms of robustness, breaking a part generally isn’t a huge deal because you probably have the spare part on the shelf.

Bottom line: good variety of product to choose from, fairly low cost, simple and robust, and mood-boosting speed and accuracy. Fixed automation is a great option for some. But not for all, because:

Weaknesses of Fixed Automation

Pretty simple: it’s not flexible. You might be able to move things a bit, but if flexibility is a key need for your application, you’ll have to look elsewhere.

We just mentioned that fixed automation is fairly easy to program, but the build of the fixed automation system itself can be tremendously complex. What’s more, there’s no manual for that system. The only people who know how it was set up are the people who built it in the first place.

Flexibility is honestly the biggest downside of fixed automation. But wouldn’t you know it, there’s a fantastic option for anyone who craves that flexibility.

Benefits of Flexible Automation

By now you’ve guessed what the key benefit is here, but I’ll say it anyway: that flexibility. Having the ability to use one robot on different products is a huge plus, and for high mix low volume environments, it’s downright huge.

As the years have progressed and robots have improved, their durability and robustness have grown to mimic fixed automation. They don’t tend to break unless accident or neglect happens. Their repeatability is good, but not as strong as some actuators. Flexible automation has too many things pulling other things around, and last I checked, physics is undefeated.

HOWEVER. For your application, you may not need repeatability as much as you need flexibility. Complete a job, and you can easily move that flexible robot to the next task. It’s a game-changer for HMLV facilities.

Weaknesses of Flexible Automation

Even the shiniest and toppest-of-the-line robots are bonafide boat anchors until someone tells them what to do. And programming that robot to capitalize on its flexibility takes real work.

But the good news is once you tell the robot what to do, it’s going to do that job consistently and without complaint for as long as you need it to. A robotics partner worth your time and budget will also provide with all the training materials you need to speed up the learning curve.

And of course, if speed is important, flexible automation might not be right for you. A good rule of thumb: if you want to move something heavier than 5 pounds in less than 5 seconds, flexible automation is probably too slow.

Where to use Fixed Automation

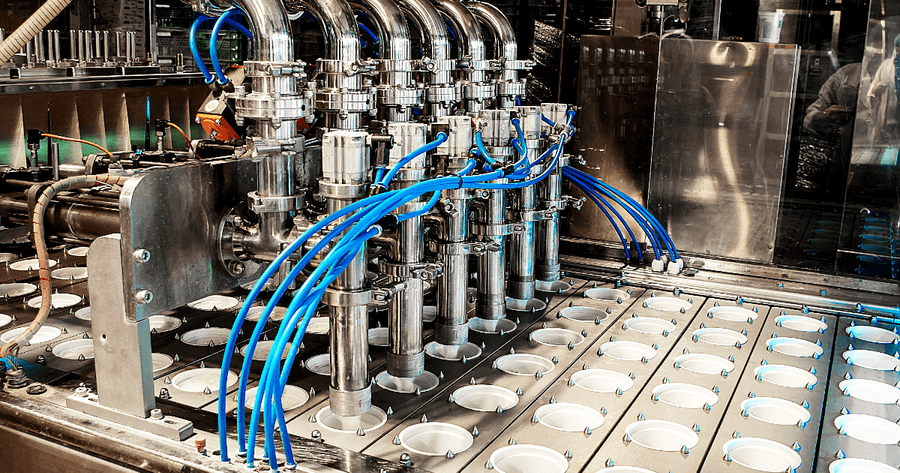

Use fixed automation on long runs of consecutive single-SKU or dual-SKU products that run for a REAL long time doing the same thing, over and over.

Couple examples: row after endless row of oil filters or food packaging coming off a conveyor line. Pick ‘em up, put ‘em over here.

A very real possibility: you might need both

We’ve implemented plenty of systems where flexible automation works closely with fixed automation. A whole lot of facilities see major benefits from doing what each system is good at: they get the speed and cost-effectiveness of fixed automation, combined with the flexible nature of robots.

Closing

You may already know this answer based on your application, but here’s the key question: which do you need: speed and repeatability, or flexibility? That answer will tell you whether you should pursue fixed automation or flexible automation.

If you have additional questions or want to know more about an application-specific offering from Kawasaki Robotics, contact us any time. We love nothing more than talking this stuff over.