When Kawasaki manufactured the first domestic industrial robot in Japan in 1969, the automotive industry was the only field utilizing robotic automation. Now, you see vastly different types of industrial robotic arms used by companies from all industries, performing both complex and simple tasks. Let’s explore how the adoption of the Kawasaki-Unimate robot paved the way for the robots we see today.

What is an industrial robot?

An industrial robot is a machine with multiple, freely-moveable, operable joints capable of performing tasks such as welding or handling heavy objects. Once movements are configured through teaching and programming, industrial robots can continue their operations accurately for hours on end, making them an essential component of modern manufacturing sites.

The Start of Automation

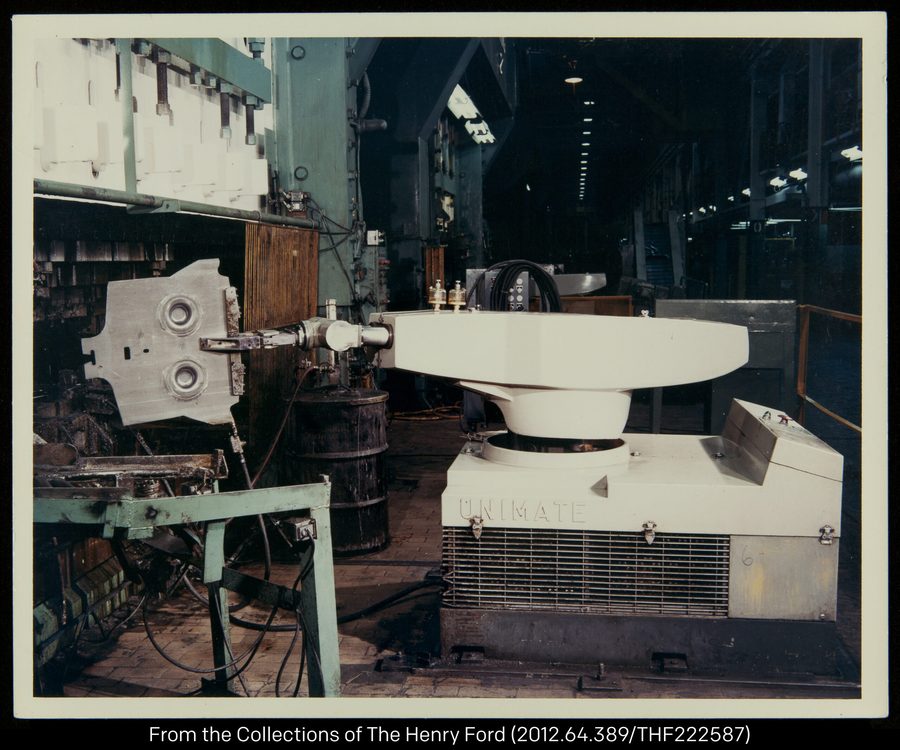

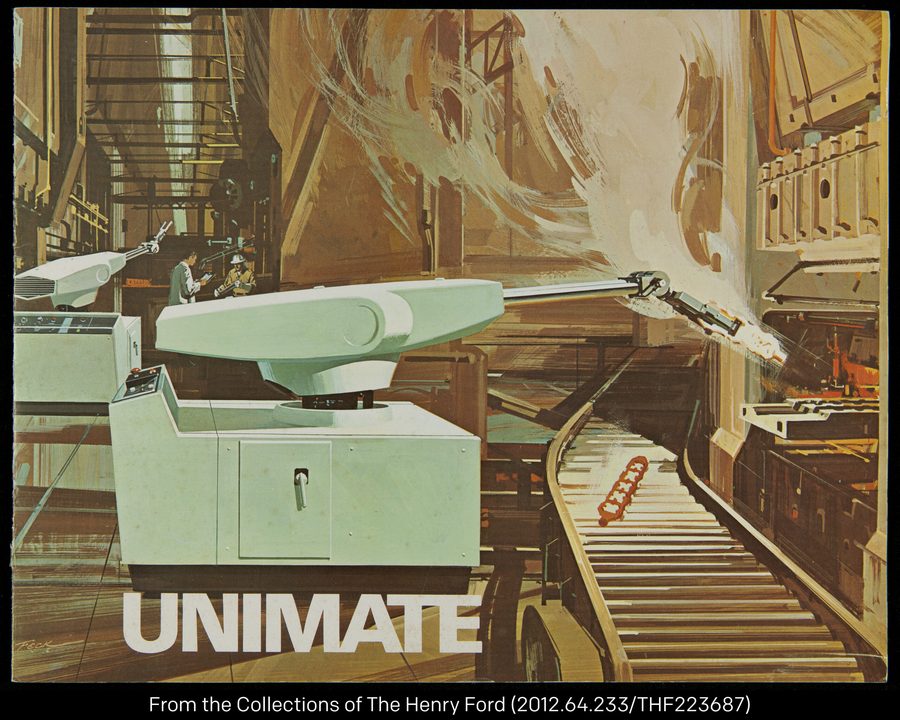

The history of industrial robots began in the 1950s. American engineer G. C. Devol, Jr. came up with the basic concept of industrial robots (automating repetitions of simple tasks) and applied for a patent in 1954. Then, J. F. Engelberger, an entrepreneur who paid a great deal of attention to this concept, established the venture company: Unimation, Inc. The Unimate, developed by the company, became the world’s first industrial robot. Because of this achievement, Engelberger came to be known as the father of robotics.

Kawasaki signed a technical license agreement with Unimation in 1968. Kawasaki sent its engineers to the United States to gain additional knowledge and import sample machines back to its factory in Japan for continuous research and development. A year later, the first industrial robot was domestically manufactured in Japan.

The Need for Automation

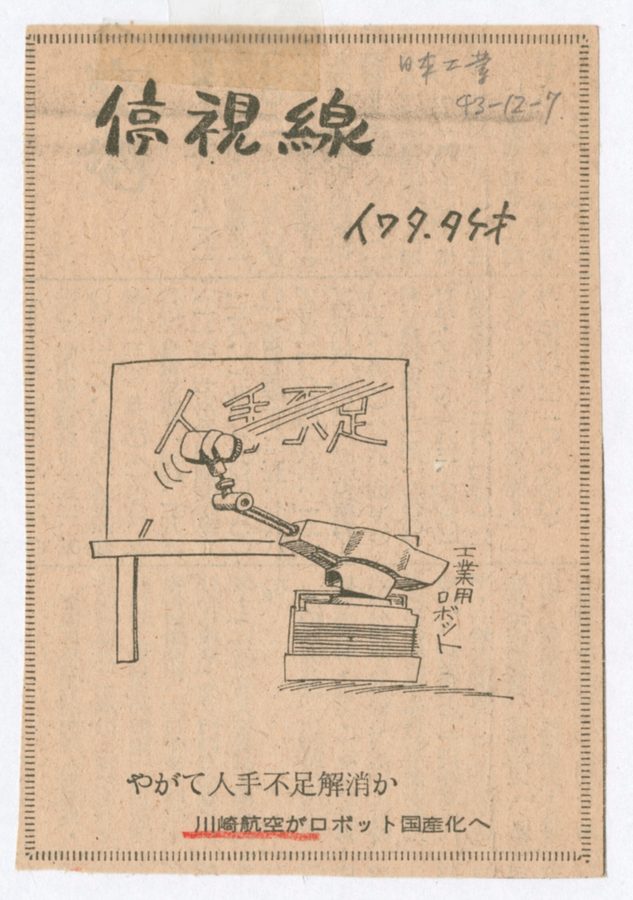

During this time, Japan was in a period of rapid economic growth. Labor shortages became a major social issue and people from rural areas were making their way to the city en masse to work. However, it still was not enough to fully alleviate the issues businesses experienced due to lack of labor.

The name “Unimate” means “working mate with universal capability.” The robot was introduced as a new type of worker that would solve labor shortage issues, setting high expectations to reduce manpower.

The first-generation “Kawasaki-Unimate 2000,” however, was not sufficient as a high-performance working mate. It was hefty, weighing in at 1.6 tons and measuring 1.6 x 1.2 x 1.3 meters, and its payload was only 12kg. It cost roughly $90k in USD, which is equivalent to approximately $595k in today’s currency. It was a very expensive device, considering the average initial monthly salary for university graduates was just over $200 USD.

Automotive Adoption

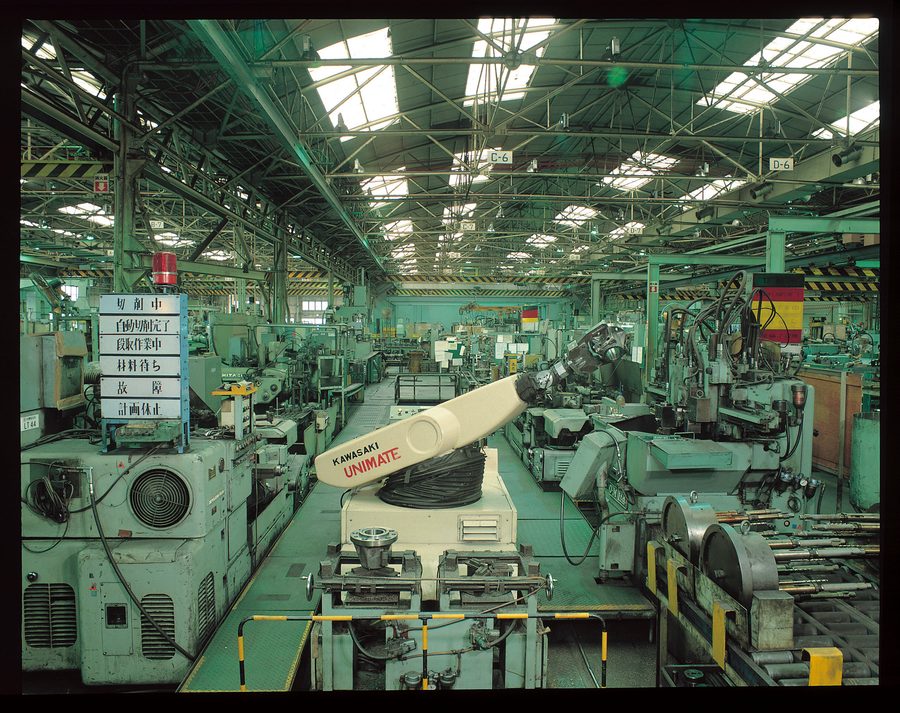

During this period, Japan saw a sharp rise in car sales thanks to the effects of rapid motorization. For the first time, it became commonplace for households to own a car for personal use. Automotive manufacturers had to automate their production lines to keep up with the booming demand.

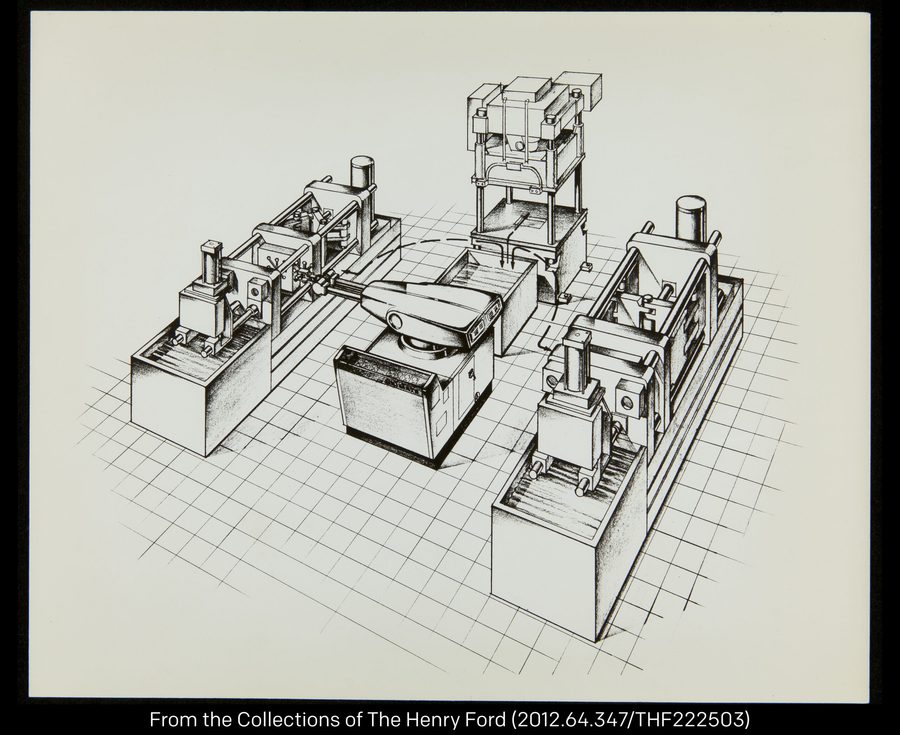

The automotive industry expressed a strong interest in these robots, but no precedent as set for these pricey machines working inside the manufacturing industry. In the most advanced car factories of the day, some manufacturing processes were already automated with dedicated devices. However, whenever the occasion called for a model change, production lines had to be reestablished from scratch, costing both time and money. But with the use of highly versatile robots, manufacturers can easily adapt to model changes by simply reprogramming the robot.

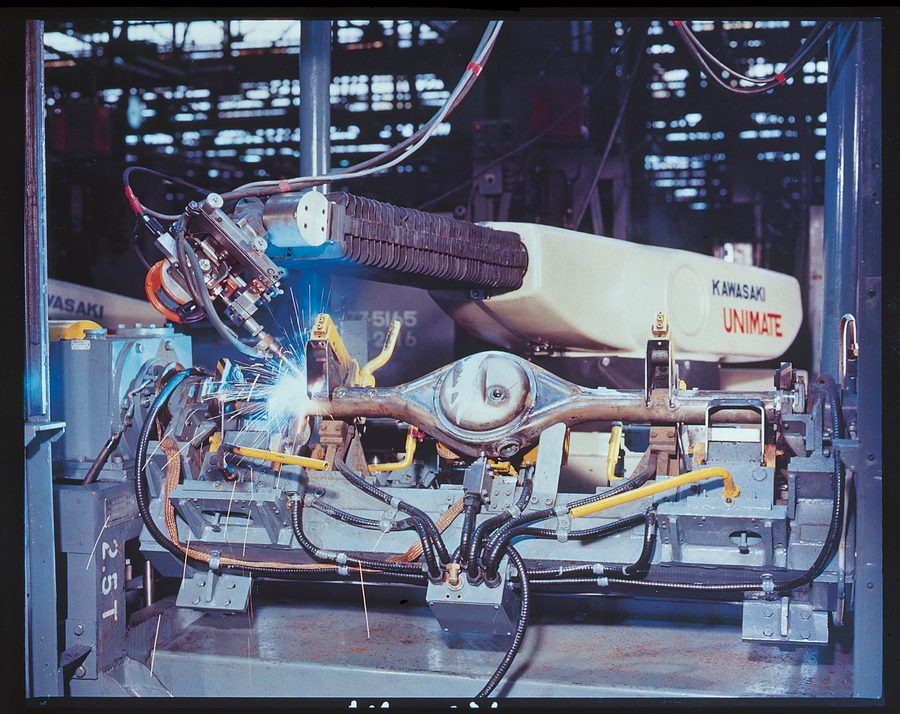

Car manufacturers began their robotic transition by automating spot welding lines – a process requiring a great deal of manpower. Completing one single automobile required spot welding an average of 4,000 pressed parts. The time and labor-intensive nature of this task made it a natural candidate for automation.

Because the first Kawasaki-Unimate 2000 was built using American specifications, Kawasaki needed to redesign it to fulfill the requirements of Japanese car manufacturers. They independently developed the 2630-type, which offered six degrees of freedom instead five, and a payload increased from 12kg to 25kg. The 2630-type was widely introduced in car factories and became a bestselling machine for years.

How Far Robotics Have Come

It has been more than 50 years since the birth of the Kawasaki-Unimate. Since then, the automotive industry has served as a catalyst for robot adoption. The overwhelming success of robots in this industry showed how beneficial automation can be for others as well. Now, industrial robots have expanded into other industries such as the electronics, food and beverage, medical, metal fabrication and more.

Not only did robotic automation improve productivity, but it also liberated workers from strenuous, monotonous jobs such as spot welding, palletizing and painting. Robots are prime candidates for tasks that fall into the 3D categories of automation: dull, dirty, and dangerous. By automating these tasks, humans can concentrate on higher level tasks that require decision-making.

Robots are no longer confined to working within the walls of factories; they are being increasingly utilized in commercial facilities and in the home as well. Similar to the way the Unimate set factory workers free from physically demanding jobs, Kawasaki robots will continue to evolve, responding to the needs of society and helping humans along the way.