- IndustriesMarine

- ApplicationsMaterial Removal, Painting

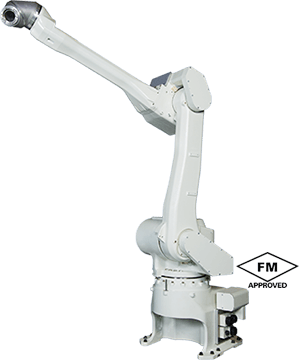

- Robot SeriesBXP/BTP series, K series

Fiber-reinforced plastic (FRP) manufacturing has long depended on the skills and intuition of experienced operators. Due to the material’s unique characteristics and the complex shapes involved, processes such as spray-up and cutting are notoriously difficult to standardize. Quality has traditionally been determined by human judgement, making automation a major technical challenge. Today, that challenge is being overcome.

In a groundbreaking project, KADO and IEC joined forces to automate the FRP manufacturing process for Kawasaki Motors’ jet skis, using industrial robots from Kawasaki Heavy Industries. Rather than simply replacing manual labor, the project focused on developing “technology that truly works on the shop floor”—automation designed around real manufacturing constraints and operator needs. The result is a practical, repeatable, and scalable robotic solution that brings consistency and mass-production capability to processes previously driven solely by human experience.

This case study explores how KADO and IEC—working closely with Kawasaki’s Robot Division—successfully automated FRP spray-up and cutting, overcoming significant on-site challenges and setting a new benchmark for composite manufacturing.

KADO x IEC: Combining Materials Expertise and System Integration

Founded in 2000, KADO began as a shipyard specialising in CFRP (carbon fiber reinforced plastic) racing yachts. From the outset, the company invested heavily in in-house R&D, developing advanced FRP molding technologies using high-performance materials, including CFRP and aramid fibers.

KADO’s technical expertise soon attracted attention beyond marine applications. When an automotive manufacturer requested support in developing a molding process, KADO expanded into industrial manufacturing—designing complete production processes rather than focusing solely on material processing. As production volumes increased, the need for stable, repeatable automation became unavoidable.

“Automation was the natural outcome of trying to stabilize our forming technology. Robots were a solution to real problems on the factory floor—not the goal itself.” explains Yasunari Kuratani, President of KADO.

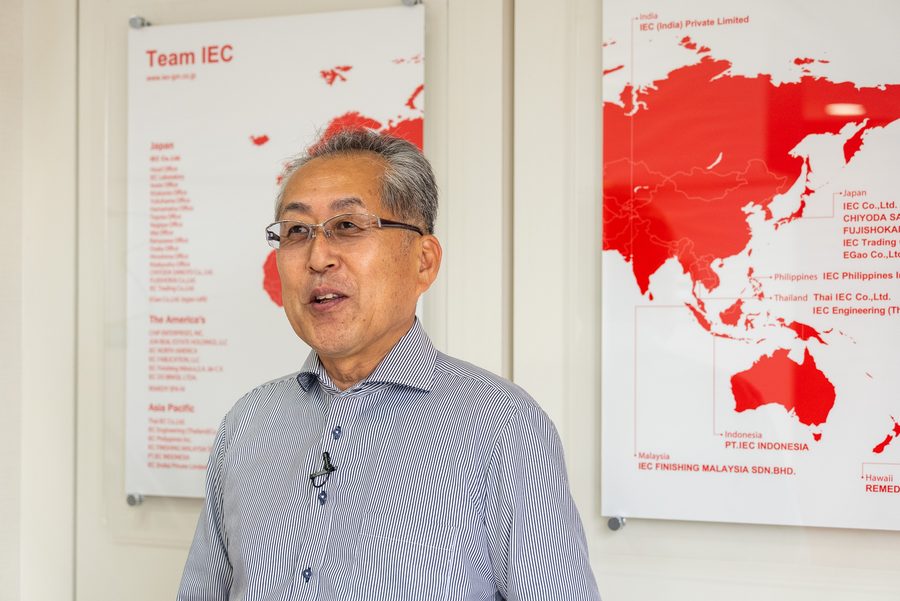

IEC Corporation, Experts in Fluid Transfer and Process Systems

IEC’s core strength lies in liquid handling, fluid transfer, and circulation supply systems. By combining robots, pumps, coating equipment, and control technologies, IEC delivers customized, proposal-driven automation solutions—primarily for the automotive industry, but increasingly for general industrial applications.

According to Kazuhiro Takeda, General Manager of IEC’s Osaka Sales Office, IEC was selected for this project because of its ability to design systems from the customer’s perspective and its demonstrated international capabilities on the factory automation project in Mexico.

Overcoming the First Major Challenge: Automating FRP Spray-Up

For IEC, automating the spray-up of glass fiber was a first.

“We knew it would be difficult—but that made it worth doing,” Takeda recalls.

The challenge lay in synchronizing the robot’s motion with the behavior of the glass fibers. Unlike paint, fiber strands can tear, stretch, or detach if not handled precisely. During commissioning, repeated adjustments were required over several days to ensure the fibers followed the robot’s movement smoothly and consistently.

Using an explosion-proof coating robot, the team fine-tuned motion paths, handling brackets, and process parameters through continuous on-site collaboration with KADO. By combining KADO’s deep understanding of fiber forming with IEC’s system-building expertise, the team successfully stabilized the spray-up process and achieved reliable automated operation.

Automating FRP Cutting: Translating Human Skill into Robotic Motion

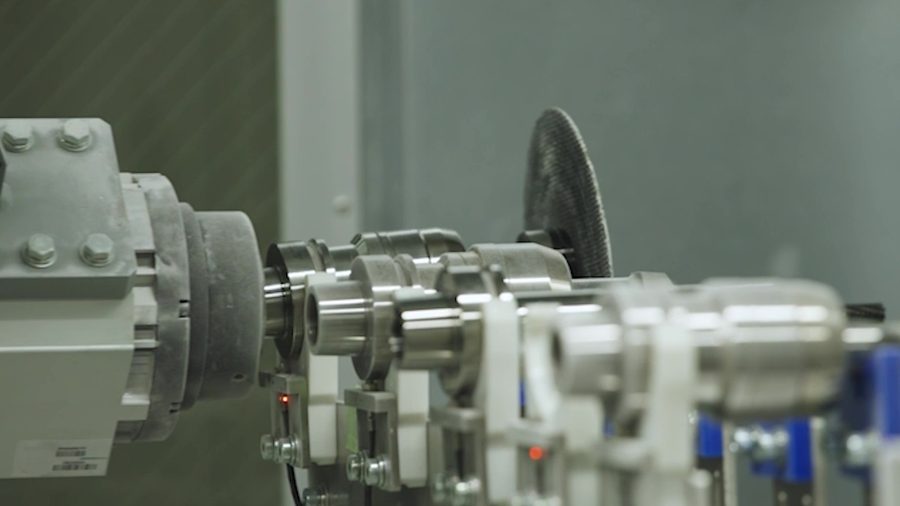

Automation of the FRP cutting process posed an equally demanding challenge for KADO. Jet ski components consist of layered materials, including gel coat and GFRP, each with different cutting characteristics. Tool selection, cutting speed, spindle rotation, vibration control, and fluctuating loads all had to be optimized.

“The most difficult part was translating the ‘feel’ of manual work into robot motion,” President Kuratani explains. “We carefully adjusted feed rates and rotation speeds while monitoring changes in cutting resistance caused by different materials.”

The solution involved robotic tool changers, carefully selected cutting tools, and extensive process tuning. Throughout development, the rigidity and motion stability of Kawasaki robots proved critical.

“Kawasaki robots offer exceptional stiffness and stable motion,” says Kuratani. “That gives us confidence when machining high-load materials like FRP. The technical support and clear design philosophy were also extremely reassuring.”

The Future of FRP Manufacturing: Digital, Scalable, and Traceable

FRP is lightweight, strong, and corrosion-resistant—qualities that are driving rapid adoption across aerospace, mobility, and next-generation transportation. Applications such as flying cars, drones, and advanced marine vehicles demand not only performance, but also reliable mass production.

For KADO, robotics is the key to that future.

By digitally managing molding processes with robots, KADO aims to optimize processing conditions based on material properties and enable full quality traceability across every production step. This approach significantly increases reliability and scalability for future FRP applications.

IEC is also expanding its focus beyond automotive manufacturing, applying its coating and handling technologies to complex materials like FRP. The Mexico project demonstrated IEC’s global capability, supported by overseas bases and strengthened further with the opening of a new office in Monterrey to enhance local after-sales support.

“Long-term trust comes from staying close to customers after delivery,” says Takeda. “We want to continue taking on new challenges—including fields like space and advanced mobility.”

Conclusion: Redefining the Role of System Integrators in Automation

This project highlights the power of collaboration. KADO’s strength in identifying on-site challenges and designing robust processes, combined with IEC’s expertise in dispensing, handling, and system integration, enabled a practical automation solution—delivered in close partnership with Kawasaki Heavy Industries.

The role of a system integrator (SIer) is no longer just to connect technologies. It is to listen to the factory floor, translate real-world feedback into engineering solutions, and bridge the gap between manufacturers and users. As AI and automation continue to advance, SIers who can unite on-site knowledge, robotics, and process design will play an increasingly vital role. The KADO × IEC project stands as a compelling example of how the future of manufacturing automation is being built—one practical solution at a time.