- IndustriesMedical

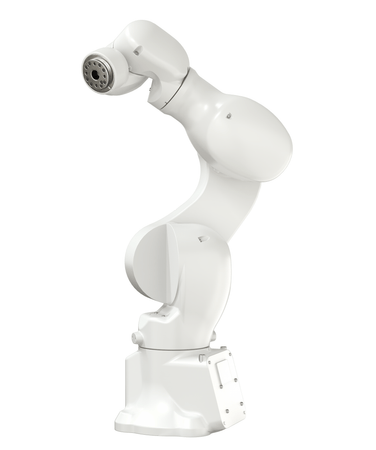

- Robot SeriesMC series

Yuyama Manufacturing was founded in November 1964 and continues to provide solutions to the medical field, where labor shortages are an issue. The company delivers systems and equipment to support various pharmaceutical operations, including dispensing equipment such as powdered medicine dispensers, as well as electronic medical records and sterilizers to the medical field. This time, we will focus on ChemoRo the Spike, an anticancer drug mixing and preparation robot developed by Yuyama Manufacturing to realize the automation of drug preparation, and the Kawasaki Robotics pharmaceutical robot MC004N, which was the driving force behind its development.

Protecting medical workers from exposure to anticancer drugs

Anticancer drugs are usually prepared manually at drug preparation sites. However, anticancer drugs made to fight cancer cells are harmful to humans, and pharmacists prepare them every day while facing that risk. Accidental exposure to radiation is a problem in itself, and there is a constant stream of women leaving their jobs due to the risk to pregnancy and childbirth. Furthermore, various issues have arisen in the medical field, such as the increased costs of using a closed drug transport system called CSTD, which is used to prevent exposure. In light of this situation, Yuyama Manufacturing was consulted about automation, and we started up the goal of automating the drug preparation of anticancer drugs to avoid risks in the medical field. This was the beginning of the development of ChemoRo.

The challenge of automation and the need for 6-axis robots

If the same movement is required for stable varieties, it is not that difficult to automate it as a dedicated device. However, the drug preparation work that was automated this time had to meet three requirements:

- Handling various varieties of drugs

- The amount changes depending on the preparation content

- Adapting to the different styles and techniques of each university and medical institution

To meet these requirements, ChemoRo’s drug preparation work needs to achieve flexible movements as close as possible to human hands, and for that reason, we decided to use a 6-axis robot with a wide range of variable techniques as the arm.In addition, the drug preparation system had to be kept in a clean environment (ISO class 5). The robots used there had to be suitable for clean environments, a specification that most manufacturers did not offer at the time. Although Yuyama Manufacturing had consulted with Kawasaki Heavy Industries, there were no plans to implement Kawasaki’s robots in ChemoRo, as Kawasaki did not have a lineup of 6-axis robots at the time. However, as Yuyama Manufacturing proceeded with the development, the technical team at Yuyama Manufacturing, impressed by Kawasaki’s polite response and sincere attitude, began to say, “We want to work together to make the project a success, taking advantage of each other’s strengths.” Kawasaki Heavy Industries was then put in charge of developing the MC004N robot, which is suitable for clean environments, and the two companies decided to work together on the ChemoRo anticancer drug preparation automation project. “It felt like Kawasaki’s sales and engineering teams could work together as one team,” says Koike, development manager at Yuyama Manufacturing, looking back on that time.

Reasons for choosing the MC series

The deciding factor for adopting the MC series in ChemoRo was that the cable is built into the arm. Conventional robots generally had their wiring coming out along with the arm, but for robots in clean environments, it was essential that the cable be built into the robot arm, considering not only appearance but also safety. “Anticancer drugs are powerful drugs, and we need to reduce the risk of accidents when handling them. If the cable is exposed, it could collide with the medicine and tip over, causing the bottle to break and spilling the medicine on the floor, so the built-in cable specification was a must,” says Kawachi (hereinafter Kawachi), development manager at Yuyama Manufacturing.

Three challenges and solutions at the time of introduction

Yuyama Manufacturing had no experience in commercializing equipment using 6-axis robots, so adopting them was a challenge in itself. “From the beginning, Kawasaki Heavy Industries supported us kindly and taught us how to use them from 1 to 10. As a result, I was able to acquire the know-how of robots myself, and the development was successful,” says Kawachi.

Development progressed as the Kawasaki Heavy Industries staff eliminated the initial hurdles, such as knowledge and anxiety about automation using robots. Pharmacists at hospitals prepare medicines in a safety cabinet, and Yuyama Manufacturing wanted to commercialize the product while maintaining the design image of the safety cabinet. With this design, it is possible to realize a layout that allows workers to wipe it clean afterwards, making it a product design that is closer to the user. Since it was difficult to imagine the robot working on a safety cabinet when placed on the floor, we adopted a so-called “ceiling-hanging” type robot that hangs from the ceiling, so that it can automatically perform the same tasks as a pharmacist.

One of the features of the MC004N is its highly accurate coordinated motion. The two robot arms, each holding a different part, work together like two human hands, enabling fine movements. However, we faced unexpected difficulties at the beginning of development. The first thing that bothered us was the stopping error of the robot’s repetitive motion. All robot manufacturers claim that the expected error is about 0.03 to 0.05 mm, but when we actually used it, we could not achieve that accuracy. This sometimes caused the needle to deviate from the intended insertion point or the machine to break down. The cause of this was on the side of the materials that the robot was holding, such as the syringes and vials. For example, when a robot grasps a syringe, it is able to grasp the center of the syringe with its hand with precision, but the bending precision of the “injection needle” attached to the tip of the syringe is unstable, so there was a problem that the grip and the needle tip were not always accurate.

“We improved the precision by repeatedly correcting the error based on the positional relationship between the robot and the needle detected by the sensor and operating it. There was also an issue with the rubber stopper that is punctured into the infusion bag, as the puncture position differs depending on the manufacturer, but by using Kawasaki Heavy Industries’ vision, the robot learned the positional relationship and was able to correctly insert the needle into the target puncture position,” says Koike. In this way, many development challenges were overcome based on Kawasaki Heavy Industries’ solutions using collaborative operation and sensing.

Effects of introduction

Koike says, “Ultimately, our goal is to automate all anticancer drug preparation.” Currently, by using machines to prescribe for hospitalized patients, he says that he has more time for human-to-human tasks, such as giving patients drug instructions. In addition, automation has ensured safety by preventing pharmacists from being exposed to radiation, but at the same time it also helps to avoid risks for patients. Conventionally, infusion bags were placed inside a safety cabinet, but this could expose the infusion bag to radiation and put patients who approached it at risk of exposure. Therefore, ChemoRo is designed to have the infusion bag placed outside the safety cabinet, ensuring the safety of everyone involved. “In more and more hospitals that have introduced it are switching to Yuyama Seisakusho for other machines. I feel that they are now evaluating our technical capabilities” (Mr. Kawachi) “ChemoRo is a product that was created with the founder’s intention of “solving real problems in the field” as a priority. I hope that ChemoRo will reduce the burden on people involved in anticancer drug preparation, even if only a little, and that it will increase the trust in our technology” (Mr. Koike)

About the future

Finally, Mr. Koike shared his thoughts as follows. “We would like Kawasaki to make the MC004N smaller. By making it less space-consuming, we think it will be easier to introduce in various fields. It is also important for ChemoRo to be known. We would like to spread awareness at academic conferences and continue to contribute to safety in the medical field.”